Woodworker's Journal 2004-28-4, страница 4

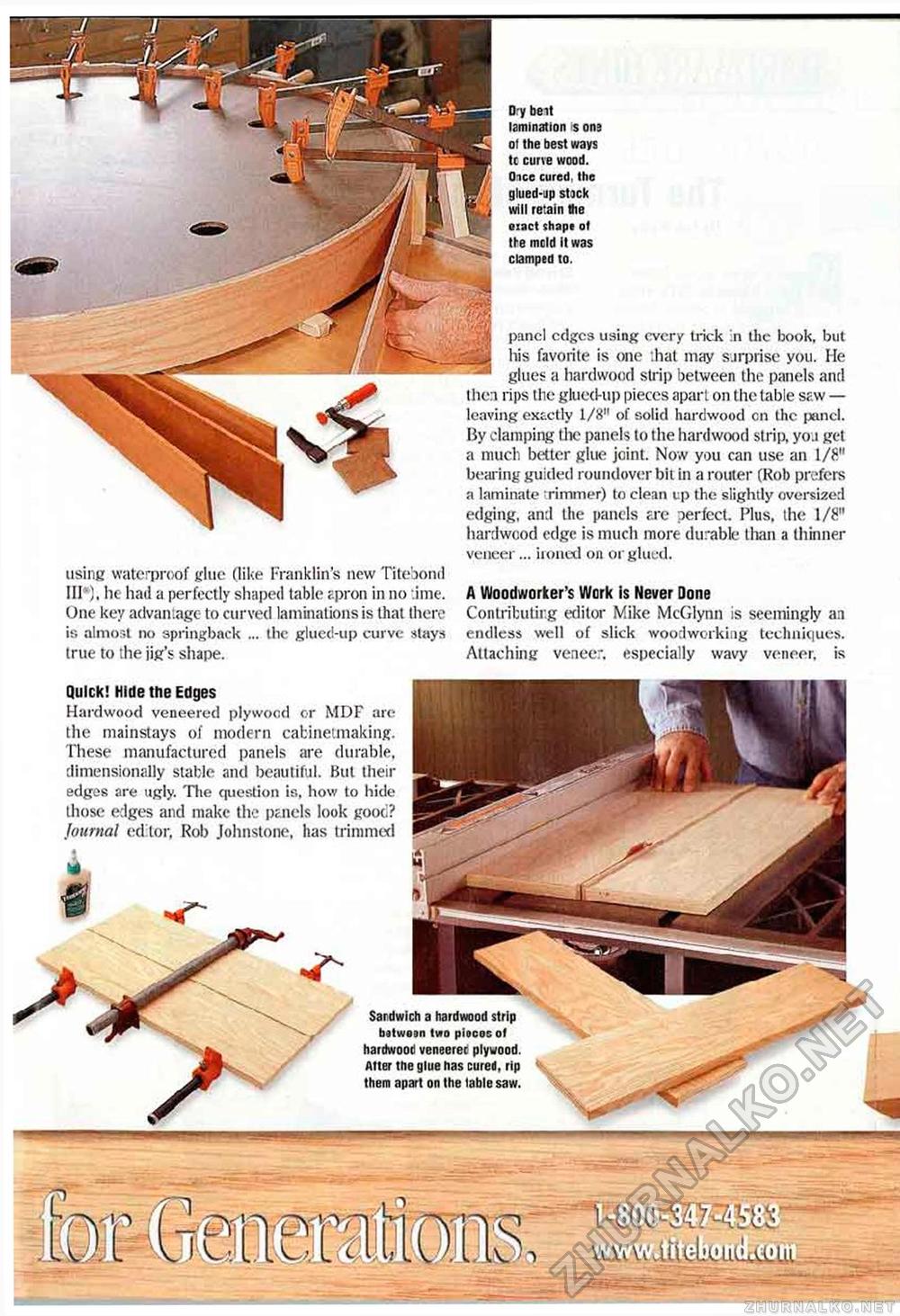

Dry belt lamination >s ons of the best ways tc curve wood. Once cured, the glued-up stack will retain the exact shape of the mold it was clamped to. using waterproof glue (like Franklin's new Titebond III*), he had a perfectly shaped table apron in no :ime. One key advantage to curved laminations is that there is almost no springback ... the glued-up curve stays true to the jig's shape. panel edges using every trick in the book, but 1 his favorite is one :hat may surprise you. Me 1 glues a hardwood strip between the panels and then rips the glued-up pieces apart on the table saw — leaving exactly 1/8" of solid hardwood on the panel. By clamping the panels to the hardwood strip, you gel a much better glue joint. Now you can use an 1/fi" bearing guided roundoverbit in a router (Rob prefers a laminate trimmer) to clean up the slightly oversized edging, and the panels are perfect Plus, the 1/8" hardwood edge is much more durable than a thinner veneer... ironed on or glued. A Woodworker's Work is Never Done Contributing editor Mike McGlynn is seemingly an endless well of slick woodworking techniques. Attaching veneer, especially wavy veneer, is Quick! Hide the Edges Hardwood veneered plywood or MDF are the mainstays of modern cabinetmaking. These manufactured panels are durable, dimensionally stable and beautiful. But their edges are ugly. The question is, how to hide those edges and make the panels look good? journal editor, Rob Johnstone, has trimmed Sandwich a hardwood strip batwean two pieces of hardwood veneerec plywood. After the glue has cured, rip them apart on the lable saw. |