Woodworker's Journal 2004-Winter, страница 20

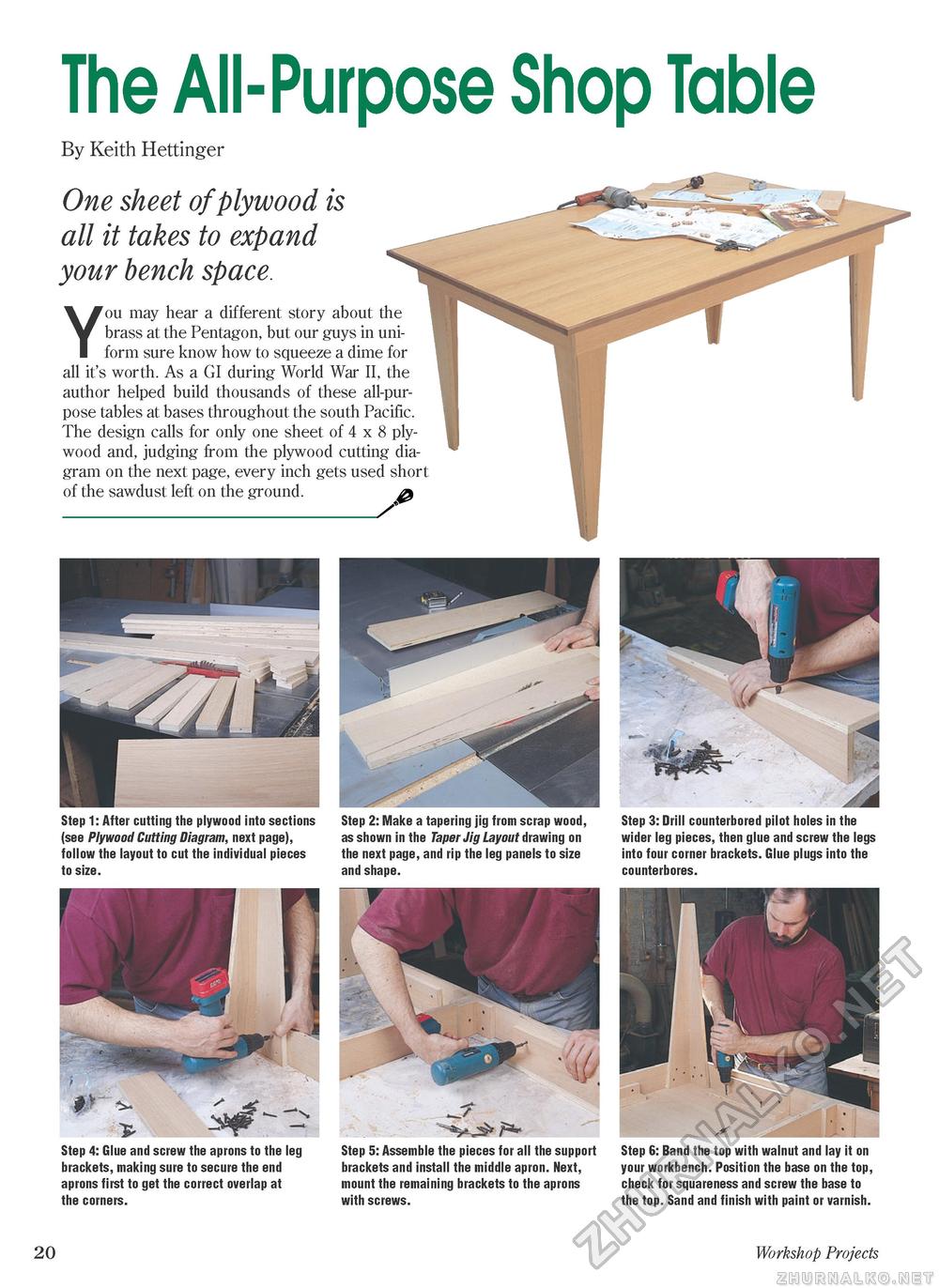

The All-Purpose Shop TableBy Keith Hettinger One sheet of plywood is all it takes to expand your bench space.You may hear a different story about the brass at the Pentagon, but our guys in uniform sure know how to squeeze a dime for all it's worth. As a GI during World War II, the author helped build thousands of these all-purpose tables at bases throughout the south Pacific. The design calls for only one sheet of 4 x 8 plywood and, judging from the plywood cutting diagram on the next page, every inch gets used short of the sawdust left on the ground. Step 1: After cutting the plywood into sections (see Plywood Cutting Diagram, next page), follow the layout to cut the individual pieces to size. Step 2: Make a tapering jig from scrap wood, as shown in the Taper Jig Layout drawing on the next page, and rip the leg panels to size and shape. Step 3: Drill counterbored pilot holes in the wider leg pieces, then glue and screw the legs into four corner brackets. Glue plugs into the counterbores. Step 4: Glue and screw the aprons to the leg brackets, making sure to secure the end aprons first to get the correct overlap at the corners. Step 5: Assemble the pieces for all the support brackets and install the middle apron. Next, mount the remaining brackets to the aprons with screws. Step 6: Band the top with walnut and lay it on your workbench. Position the base on the top, check for squareness and screw the base to the top. Sand and finish with paint or varnish. 20 * Workshop Projects |