Woodworker's Journal 2006-30-2, страница 22

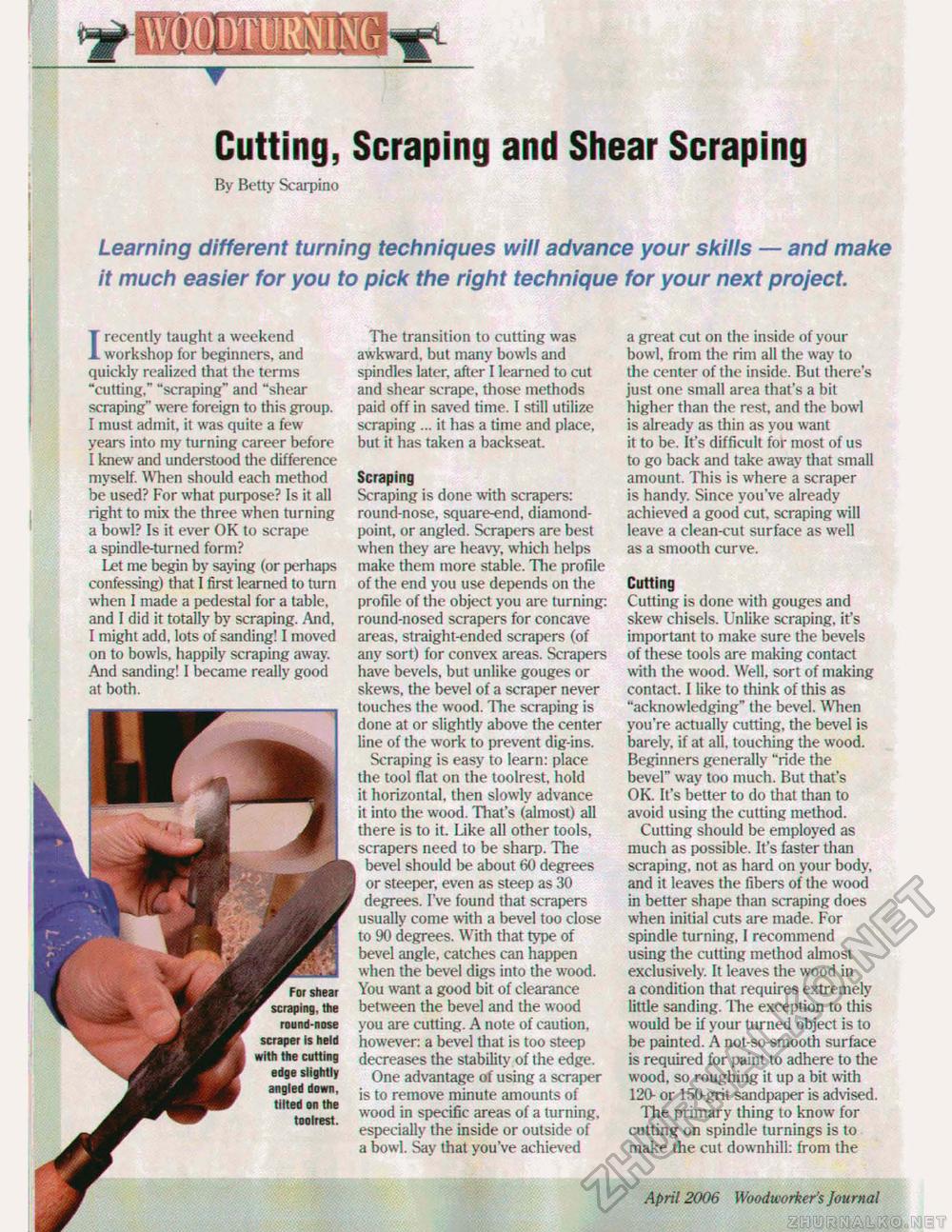

Cutting, Scraping and Shear Scraping By Betty Scarpino Learning different turning techniques will advance your skills — and make it much easier for you to pick the right technique for your next project. I recently taught a weekend workshop for beginners, and quickly realized that the terms "cutting," "scraping" and "shear scraping" were foreign to this group. I must admit, it was quite a few years into my turning career before I knew and understood the difference myself. When should each method be used? For what purpose? Is it all right to mix the three when turning a bowl? Is it ever OK to scrape a spindle-turned form? Let me begin by saying (or perhaps confessing) that I first learned to turn when I made a pedestal for a table, and I did it totally by scraping. .And, I might add, lots of sanding! I moved on to bowls, happily scraping away. And sanding! I became really good at both. shear scraping, the round-nose scraper is held with the cutting edge slightly angled dawn, tilted an the toolrest. The transition to cutting was awkward, but many bowls and spindles later, after I learned to cut and shear scrape, those methods paid off in saved time. I still utilize scraping ... it has a time and place, but it has taken a backseat. Scraping Scraping is done with scrapers: round-nose, square-end, diamond-point, or angled. Scrapers are best when they are heavy, which helps make them more stable. The profile of the end you use depends on the profile of the object you are turning: round-nosed scrapers for concave areas, straight-ended scrapers (of any sort) for convex areas. Scrapers have bevels, but unlike gouges or skews, the bevel of a scraper never touches the wood. Hie scraping is done at or slightly above the center line of the work to prevent dig-ins. Scraping is easy to learn: place the tool flat on the toolrest, hold it horizontal, then slowly advance it into the wood. That's (almost) all there is to it. Like all other tools, scrapers need to be sharp. The bevel should lie about 60 degrees or steeper, even as steep as 30 degrees. I've found that scrapers usually come with a bevel too close to 90 degrees. With that type of bevel angle, catches can happen when the bevel digs into the wood. You want a good bit of clearance between the bevel and the wood you are cutting. A note of caution, however: a bevel that is too steep decreases the stability of the edge. One advantage of using a scraper is to remove minute amounts of wood in specific areas of a turning, especially the inside or outside of a bowl. Say that you've achieved a great cut on the inside of your bowl, from the rim all the way to the center of the inside. But there's just one small area that's a bit higher than the rest, and the bowl is already as thin as you want it to be. It's difficult for most of us to go back and take away that small amount. This is where a scraper is handy. Since you've already achieved a good cut. scraping will leave a clean-cut surface as well as a smooth curve. Cutting Cutting is done with gouges and skew chisels. Unlike scraping, it's important to make sure the bevels of these tools are making contact with the wood. Well, sort of making contact. I like to think of this as "acknowledging" the bevel. When you're actually cutting, the bevel is barely, if at all. touching the wTood. Beginners generally "ride the bevel" way too much. But that's OK. It's better to do that than to avoid using the cutting method. Cutting should be employed as much as possible. It's faster than scraping, not as hard on your body, and it leaves the fibers of ihe wood in better shape than scraping does when initial cuts are made. For spindle turning, I recommend using the cutting method almost exclusively. It leaves the wood in a condition that requires extremely little sanding. The exception to this would be if your turned object is to be painted. A not-so-smooth surface is required for paint to adhere to the wood, so roughing it up a bit with 120- or 150-grit sandpaper is advised. The primary thing to know for cutting on spindle turnings is to make the cut downhill: from the 22 April 2006 Woodworker's Journal |