Woodworker's Journal 2008-32-1, страница 10

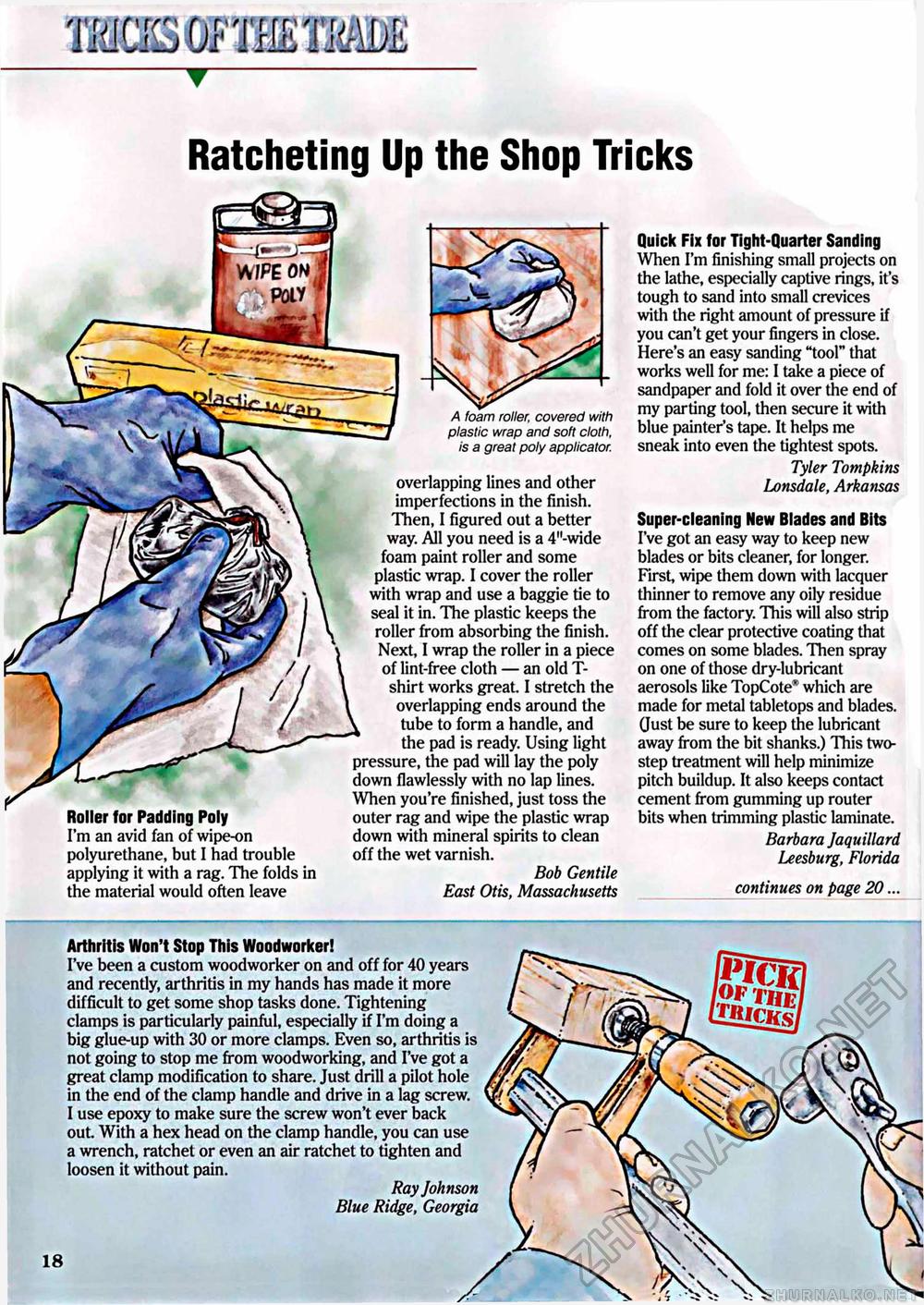

miGO nm*mm -▼- Tricks Quick Fix for Tight-Quarter Sanding When I'm finishing small projects on the lathe, especially captive rings, it's tough to sand into small crevices with the right amount of pressure if you can't get your fingers in close. Here's an easy sanding "tool" that works well for me: I take a piece of sandpaper and fold it over the end of my parting tool, then secure it with blue painter's tape. It helps me sneak into even the tightest spots. Tyler Tompkins Lonsdale, Arkansas Super-cleaning New Blades and Bits I've got an easy way to keep new blades or bits cleaner, for longer. First, wipe them down with lacquer thinner to remove any oily residue from the factory. This will also strip off the clear protective coating that comes on some blades. Then spray on one of those dry-lubricant aerosols like TopCote* which are made for metal tabletops and blades. Gust be sure to keep the lubricant away from the bit shanks.) This two-step treatment will help minimize pitch buildup. It also keeps contact cement from gumming up router bits when trimming plastic laminate. Barbara Jaquillard Leesburg, Florida _continues on page 20... Ratcheting Up the Shop Roller for Padding Poly I'm an avid fan of wipe-on polyurethane, but I had trouble applying it with a rag. The folds in the material would often leave A foam roller, covered with plastic wrap and soft cloth, is a great poly applicator. overlapping lines and other imperfections in the finish. Then, I figured out a better way. All you need is a 4"-wide foam paint roller and some plastic wrap. I cover the roller with wrap and use a baggie tie to seal it in. The plastic keeps the roller from absorbing the finish. Next, I wrap the roller in a piece of lint-free cloth — an old T-shirt works great. I stretch the overlapping ends around the tube to form a handle, and the pad is ready. Using light pressure, the pad will lay the poly down flawlessly with no lap lines. When you're finished, just toss the outer rag and wipe the plastic wrap down with mineral spirits to clean off the wet varnish. Bob Gentile East Otis, Massachusetts Arthritis Won't Stop This Woodworker! I've been a custom woodworker on and off for 40 years and recently, arthritis in my hands has made it more difficult to get some shop tasks done. Tightening clamps is particularly painful, especially if I'm doing a big glue-up with 30 or more clamps. Even so, arthritis is not going to stop me from woodworking, and I've got a great clamp modification to share. Just drill a pilot hole in the end of the clamp handle and drive in a lag screw. I use epoxy to make sure the screw won't ever back out. With a hex head on the clamp handle, you can use a wrench, ratchet or even an air ratchet to tighten and loosen it without pain. Ray Johnson Blue Ridge, Georgia |