Woodworker's Journal 2008-32-1, страница 13

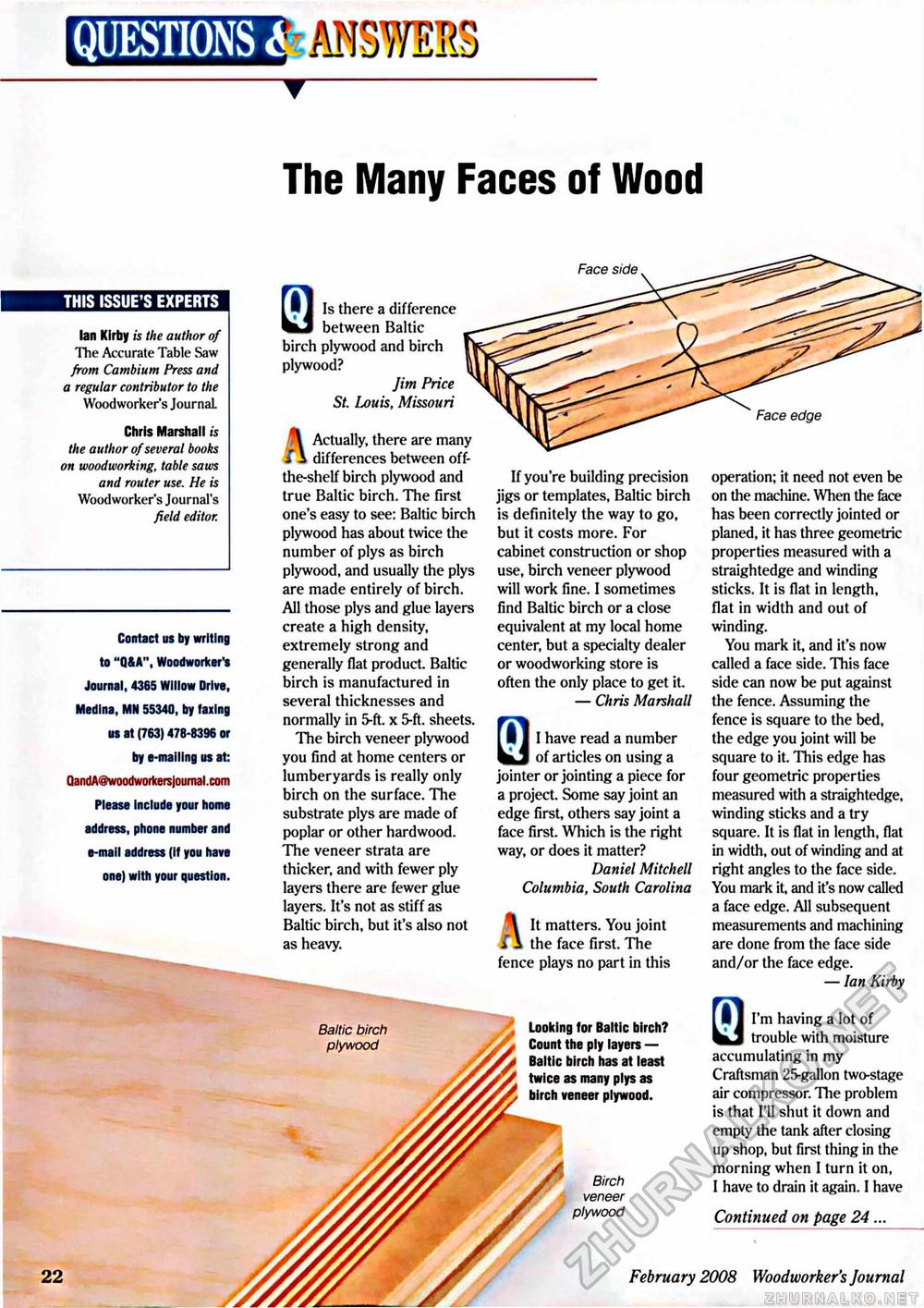

QUESTIONS I ANSWERS The Many Faces of Wood Face side THIS ISSUE S EXPERTS Ian Kirby is the author of The Accurate Table Saw from Cambium Press and a regular contributor to the Woodworker's Journal. Chris Marshall is the author of several books on woodworking, table saws and router use. He is Woodworker's Journal's field editor. Contact us by writing to "Q&A", Woodworker's Journal, 4365 Willow Drive, Medina, MN 55340, by faxing us at (763) 478-8396 or by e-mailing us at: QandA@woodwoikerejoumal. com Please Include your home address, phone number and e-mail address (If you have one) with your question. a Is there a difference between Baltic birch plywood and birch plywood? Jim Price St. Louis, Missouri ■\ Actually, there are many Tl differences between off-the-shelf birch plywood and true Baltic birch. The first one's easy to see: Baltic birch plywood has about twice the number of plys as birch plywood, and usually the plys are made entirely of birch. All those plys and glue layers create a high density, extremely strong and generally flat product. Baltic birch is manufactured in several thicknesses and normally in 5-ft. x 5-ft. sheets. The birch veneer plywood you find at home centers or lumberyards is really only birch on the surface. The substrate plys are made of poplar or other hardwood. The veneer strata are thicker, and with fewer ply layers there are fewer glue layers. It's not as stiff as Baltic birch, but it's also not as heavy. Baltic birch plywood 22 If you're building precision jigs or templates, Baltic birch is definitely the way to go, but it costs more. For cabinet construction or shop use, birch veneer plywood will work fine. I sometimes find Baltic birch or a close equivalent at my local home center, but a specialty dealer or woodworking store is often the only place to get it — Chris Marshall 0 I have read a number of articles on using a jointer or jointing a piece for a project. Some say joint an edge first, others say joint a face first. Which is the right way, or does it matter? Daniel Mitchell Columbia, South Carolina ^ It matters. You joint i \ the face first. The fence plays no part in this Looking for Baltic birch? Count the ply layers — birch has at least as many plys as veneer plywood. Birch veneer plywood Face edge operation; it need not even be on the machine. When the face has been correctly jointed or planed, it has three geometric properties measured with a straightedge and winding sticks. It is flat in length, flat in width and out of winding. You mark it, and it's now called a face side. This face side can now be put against the fence. Assuming the fence is square to the bed, the edge you joint will be square to it. This edge has four geometric properties measured with a straightedge, winding sticks and a try square. It is flat in length, flat in width, out of winding and at right angles to the face side. You mark it, and it's now called a face edge. All subsequent measurements and machining are done from the face side and/or the face edge. — Ian Kirby 0 I'm having a lot of trouble with moisture accumulating in my Craftsman 25-gallon two-stage air compressor. The problem is that I'll shut it down and empty the tank after closing up shop, but first thing in the morning when I turn it on, I have to drain it again. I have Continued on page 24... February 2008 Woodworker's Journal |