Woodworker's Journal 2008-32-1, страница 33

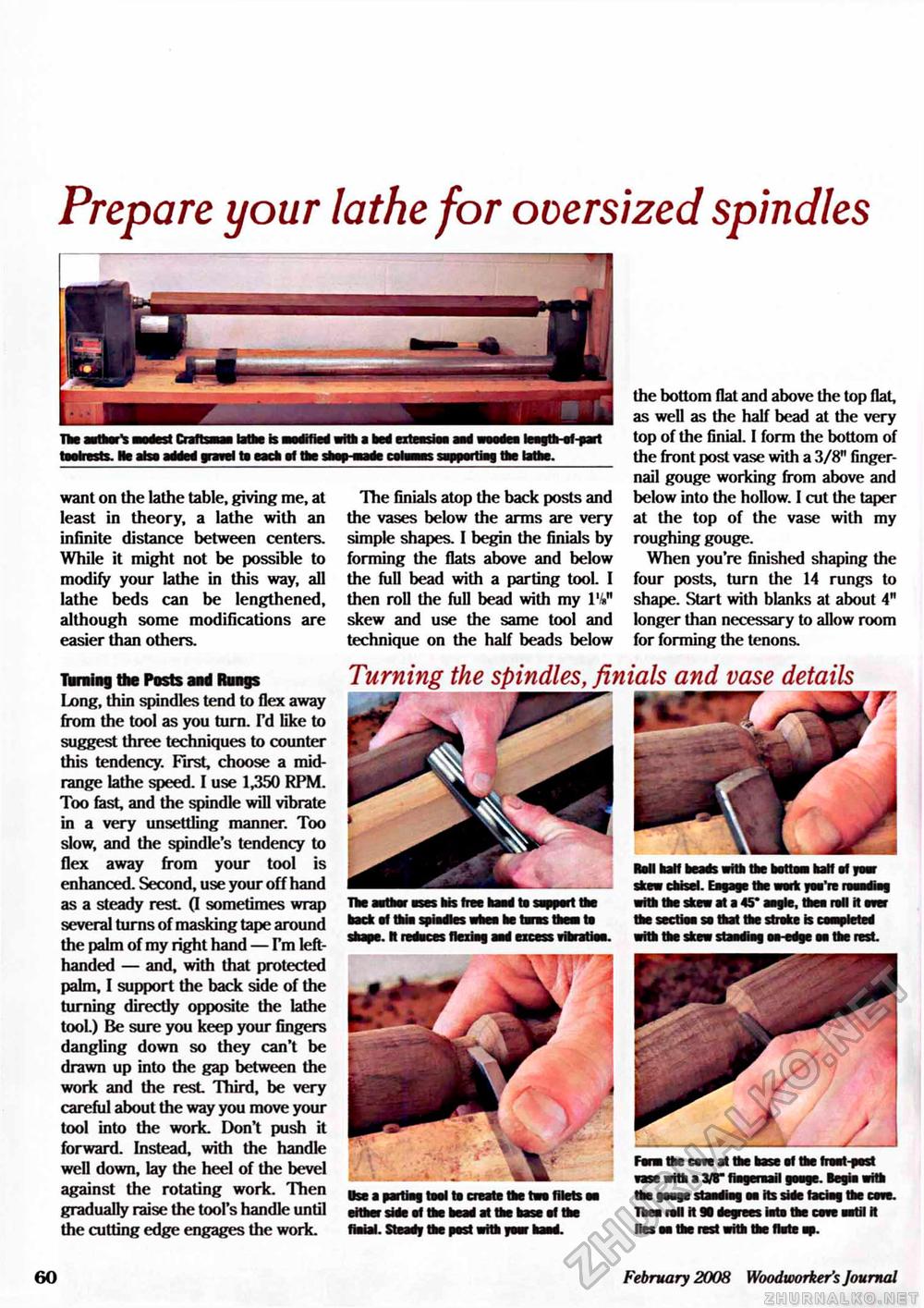

Prepare your lathe for oversized spindles Hm lather's Mtot Cnftsm laths is a^fM villi a bed eiteeiiea aad woedea leegth of-part taahmti- He alsa added gravel te each ef the shep-aade calaaas lappwtiag the lathe. want on the lathe table, giving me, at least in theory, a lathe with an infinite distance between centers. While it might not be possible to modify your lathe in this way, all lathe beds can be lengthened, although some modifications are easier than others. The finials atop the back posts and the vases below the arms are very simple shapes. I begin the finials by forming the flats above and below the full bead with a parting tool. I then roll the fiill bead with my 1%" skew and use the same tool and technique on the half beads below the bottom flat and above the top flat, as well as the half bead at the very top of the finial. I form the bottom of the front post vase with a 3/8" fingernail gouge working from above and below into the hollow. I cut the taper at the top of the vase with my roughing gouge. When you're finished shaping the four posts, turn the 14 rungs to shape. Start with blanks at about 4" longer than necessary to allow room for forming the tenons. Taming the Posts awl Rungs Long, thin spindles tend to flex away from the tool as you turn. I'd like to suggest three techniques to counter this tendency. First, choose a mid-range lathe speed. I use 1,350 RPM. Too fast, and the spindle will vibrate in a very unsettling manner. Too slow, and the spindle's tendency to flex away from your tool is enhanced. Second, use your off hand as a steady rest (I sometimes wrap several turns of masking tape around the palm of my right hand — I'm left-handed — and, with that protected palm, I support the back side of the turning directly opposite the lathe tool.) Be sure you keep your fingers dangling down so they can't be drawn up into the gap between the work and the rest Third, be very careful about the way you move your tool into the work. Don't push it forward. Instead, with the handle well down, lay the heel of the bevel against the rotating work. Then gradually raise the tool's handle until the cutting edge engages the work. Use a partial teel te create the tn filets ea either side ef the bead at the hase ef the ftaaal. Steady the past with year haad. Fane the cave at the hase ef the treat-pest vase with a 3/8" ftegereatl geage. Begia with the peage staadiag ee its side faciag the ceve. Them rail it 90 degrees iata the cave aatil ft lies ea the rest with the flate ap. Turning the spindles, finials and vase details The aether ases his free haad ta s^pert the back ef Urn spiadles whea he tares theai te shape. It redaces flexiag aad excess vihratiee. Hall half beads with the betteai half ef year skew chisel. Eagage the werk yea're rendiag with the skew at a 45* aagle, thea rail it ever the sectiee se that the strake is cea^ieted with the skew itiadiag ea edge ee the rest. 60 February 2008 Woodworker's Journal |