Woodworker's Journal 2008-32-1, страница 34

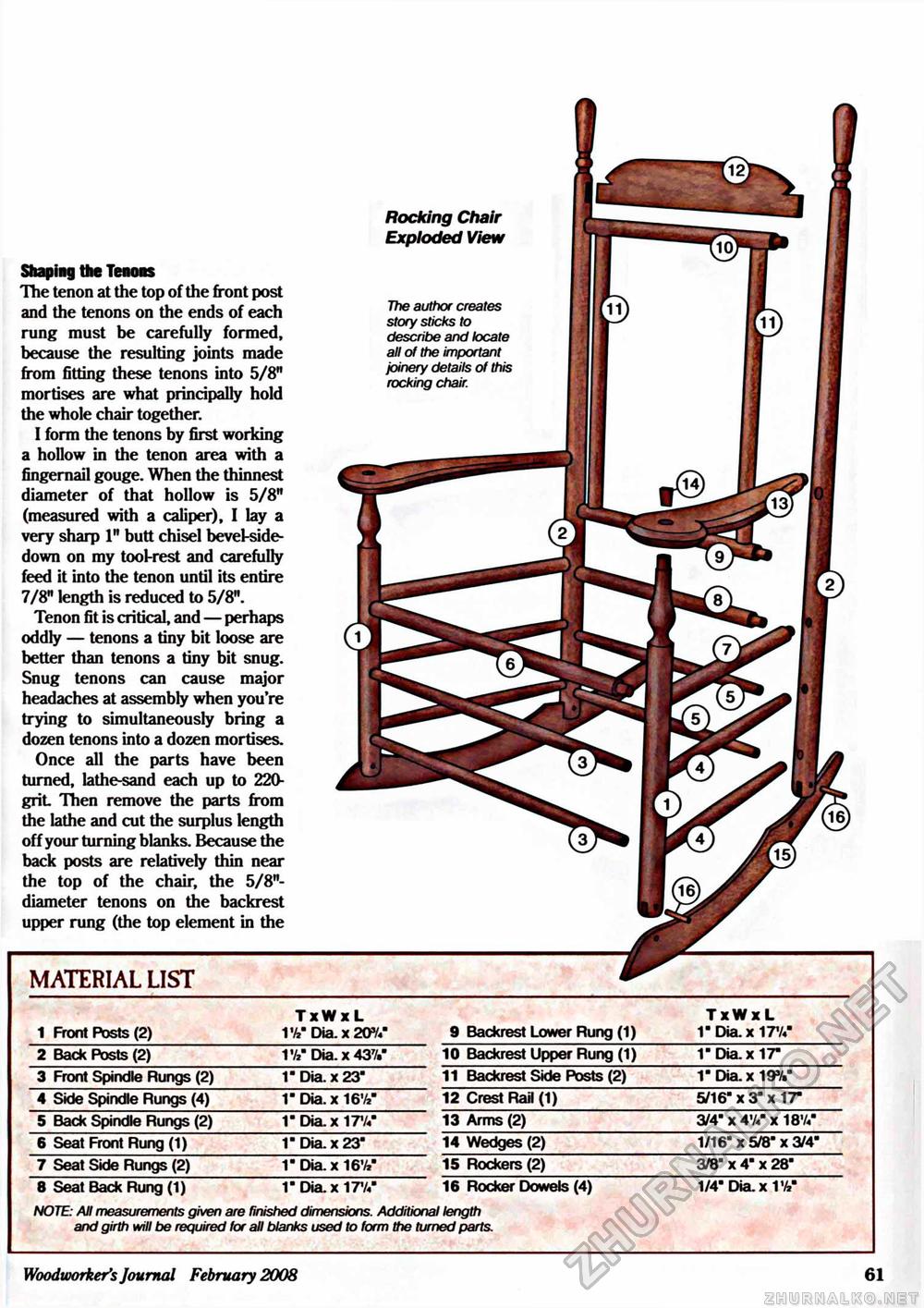

MATERIAL LIST TxWxL TxWxL 1 Front Posts (2) 1V Dia. x 207/ 9 Backrest Lower Rung (1) 1" Dia. x 177/ 2 Back Posts (2) 1 V Dia. x 437." 10 Backrest Upper Rung (1) 1' Dia. x 17" 3 Front Spindle Rungs (2) 1" Dia. x 23" 11 Backrest Side Posts (2)_1' Pia.x 19V 4 Side Spindle Rungs (4) 1" Dia. x 16V 12 Crest Rail (1) 5/16" x 3" x 17" 5 Back Spindle Rungs (2) 1" Dia. x 17V 13 Arms (2) 3/4" x 47/ x 187/ 6 Seat Front Rung (1) 1" Dia. x 23" 14 Wedges (2) 1/16" x 5/8" x 3/4" 7 Seat Side Rungs (2) 1" Dia. x 16V 15 Rockers (2) 3/8" x 4" x 28" 8 Seat Back Rung (1) 1" Dia. x 177/ 16 Rocker Dowels (4) 1/4" Dia. x 1V NOTE: All measurements given are finished dimensions. Additional length and girth will be required for all blanks used to form the turned parts. Shaping the Tenons The tenon at the top of the front post and the tenons on the ends of each rung must be carefully formed, because the resulting joints made from fitting these tenons into 5/8" mortises are what principally hold the whole chair together. I form the tenons by first working a hollow in the tenon area with a fingernail gouge. When the thinnest diameter of that hollow is 5/8" (measured with a caliper), I lay a very sharp 1" butt chisel bevel-side-down on my tool-rest and carefully feed it into the tenon until its entire 7/8" length is reduced to 5/8". Tenon fit is critical, and — perhaps oddly — tenons a tiny bit loose are better than tenons a tiny bit snug. Snug tenons can cause major headaches at assembly when you're trying to simultaneously bring a dozen tenons into a dozen mortises. Once all the parts have been turned, lathe-sand each up to 220-griL Then remove the parts from the lathe and cut the surplus length off your turning blanks. Because the back posts are relatively thin near the top of the chair, the 5/8"-diameter tenons on the backrest upper rung (the top element in the Rocking Chair Exploded View The author creates story sticks to describe and locate all of the important joinery details of this rocking chair Woodworker's Journal February 2008 61 |