Woodworker's Journal 2008-32-2, страница 38

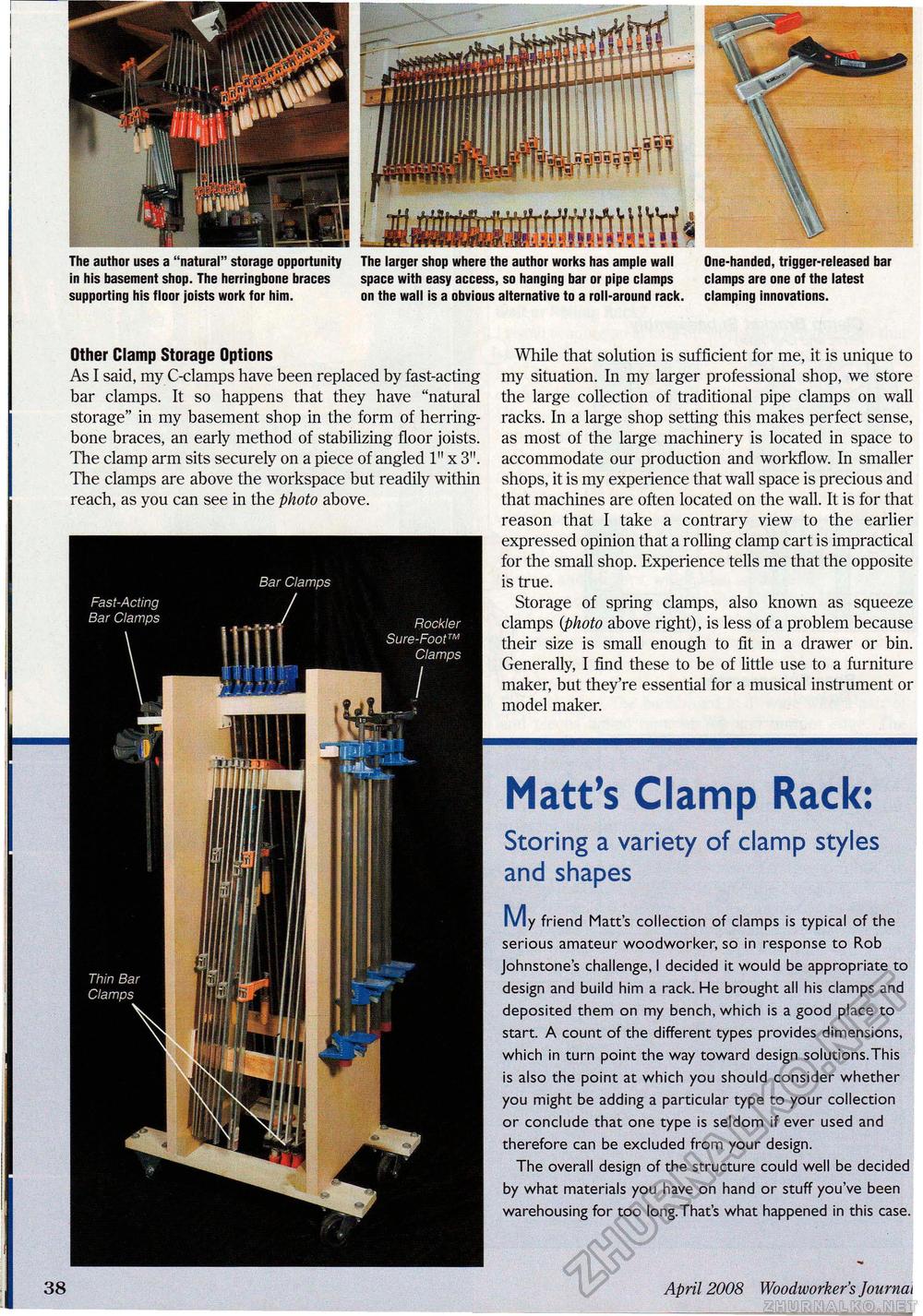

The author uses a "natural" storage opportunity in his basement shop. The herringbone braces supporting his floor joists work for him. The larger shop where the author works has ample wall space with easy access, so hanging bar or pipe clamps on the wall is a obvious alternative to a roll-around rack, One-handed, trigger-released bar clamps are one of the latest clamping innovations. While that solution is sufficient for me, it is unique to my situation. In my larger professional shop, we store the large collection of traditional pipe clamps on wall racks. In a large shop setting this makes perfect sense, as most of the large machinery is located in space to accommodate our production and workflow. In smaller shops, it is my experience that wall space is precious and that machines are often located on the wall. It is for that reason that I take a contrary view to the earlier expressed opinion that a rolling clamp cart is impractical for the small shop. Experience tells me that the opposite is true. Storage of spring clamps, also known as squeeze clamps (photo above right), is less of a problem because their size is small enough to fit in a drawer or bin. Generally, I find these to be of little use to a furniture maker, but they're essential for a musical instrument or model maker. Other Clamp Storage Options As I said, my C-clamps have been replaced by fast-acting bar clamps. It so happens that they have "natural storage" in my basement shop in the form of herringbone braces, an early method of stabilizing floor joists. The clamp arm sits securely on a piece of angled 1" x 3". The clamps are above the workspace but readily within reach, as you can see in the photo above. Matt's Clamp Rack: Storing a variety of clamp styles and shapes My friend Matt's collection of clamps is typical of the serious amateur woodworker, so in response to Rob Johnstone's challenge, I decided it would be appropriate to design and build him a rack. He brought all his clamps and deposited them on my bench, which is a good place to start. A count of the different types provides dimensions, which in turn point the way toward design solutions.This is also the point at which you should consider whether you might be adding a particular type to your collection or conclude that one type is seldom if ever used and therefore can be excluded from your design. The overall design of the structure could well be decided by what materials you have on hand or stuff you've been warehousing for too long.That's what happened in this case. 38 April 2008 Woodworker's Journal |