Woodworker's Journal 2008-32-2, страница 36

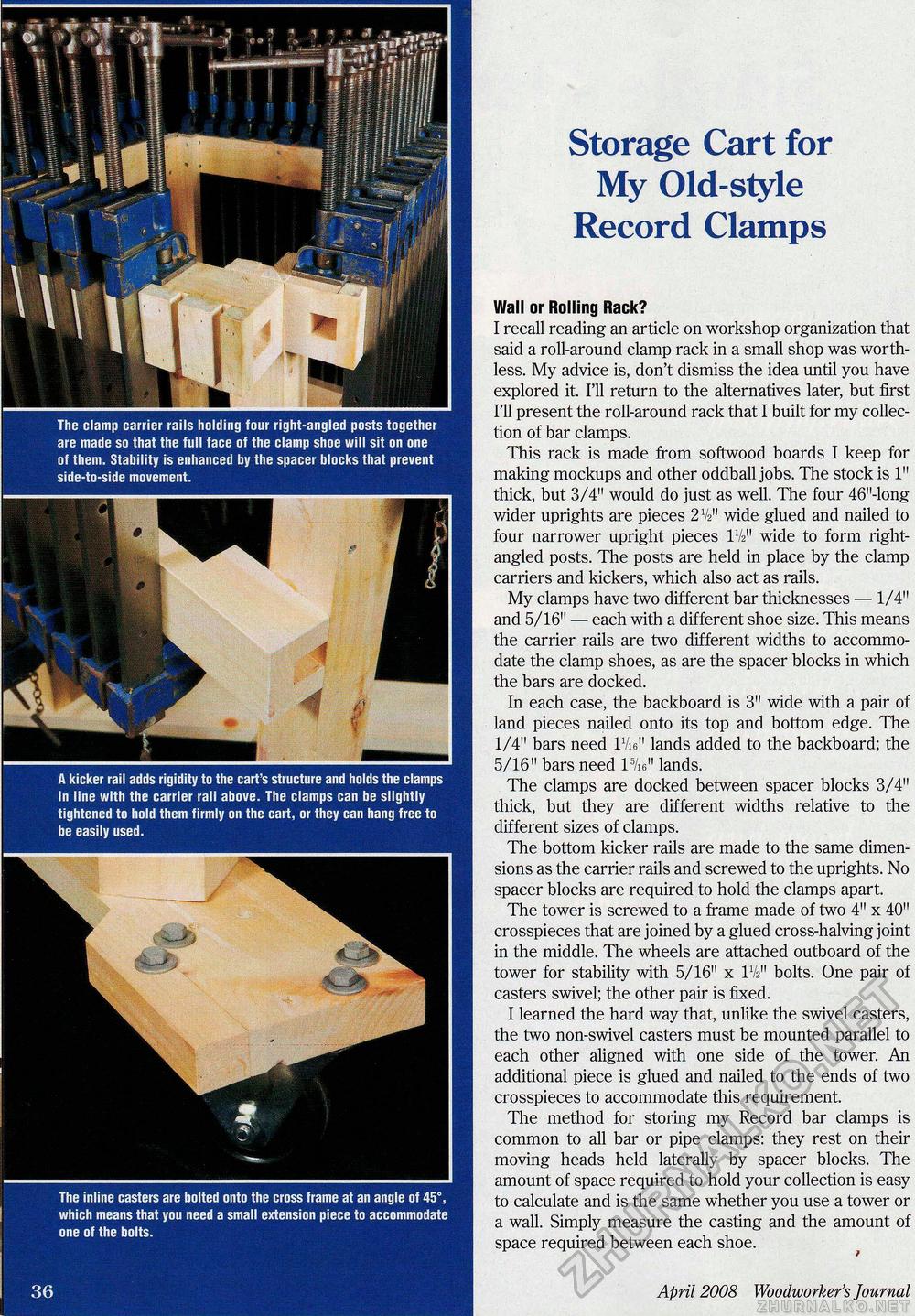

The clamp carrier rails holding four right-angled posts together are made so that the full face of the clamp shoe will sit on one of them. Stability is enhanced by the spacer blocks that prevent side-to-side movement. A kicker rail adds rigidity to the cart's structure and holds the clamps in line with the carrier rail above. The clamps can be slightly tightened to hold them firmly on the cart, or they can hang free to be easily used. The inline casters are bolted onto the cross frame at an angle of 45°, which means that you need a small extension piece to accommodate one of the bolts. Storage Cart for My Old-style Record Clamps Wall or Rolling Rack? I recall reading an article on workshop organization that said a roll-around clamp rack in a small shop was worthless. My advice is, don't dismiss the idea until you have explored it. I'll return to the alternatives later, but first I'll present the roll-around rack that I built for my collection of bar clamps. This rack is made from softwood boards I keep for making mockups and other oddball jobs. The stock is 1" thick, but 3/4" would do just as well. The four 46"-long wider uprights are pieces 2V2" wide glued and nailed to four narrower upright pieces IV2'1 wide to form right-angled posts. The posts are held in place by the clamp carriers and kickers, which also act as rails. My clamps have two different bar thicknesses — 1/4" and 5/16" — each with a different shoe size. This means the carrier rails are two different widths to accommodate the clamp shoes, as are the spacer blocks in which the bars are docked. In each case, the backboard is 3" wide with a pair of land pieces nailed onto its top and bottom edge. The 1/4" bars need lVis" lands added to the backboard; the 5/16" bars need Vhe" lands. The clamps are docked between spacer blocks 3/4" thick, but they are different widths relative to the different sizes of clamps. The bottom kicker rails are made to the same dimensions as the carrier rails and screwed to the uprights. No spacer blocks are required to hold the clamps apart. The tower is screwed to a frame made of two 4" x 40" crosspieces that are joined by a glued cross-halving joint in the middle. The wheels are attached outboard of the tower for stability with 5/16" x IV2" bolts. One pair of casters swivel; the other pair is fixed. I learned the hard way that, unlike the swivel casters, the two non-swivel casters must be mounted parallel to each other aligned with one side of the tower. An additional piece is glued and nailed to the ends of two crosspieces to accommodate this requirement. The method for storing my Record bar clamps is common to all bar or pipe clamps: they rest on their moving heads held laterally by spacer blocks. The amount of space required to hold your collection is easy to calculate and is the same whether you use a tower or a wall. Simply measure the casting and the amount of space required between each shoe. 36 April 2008 Woodworker's Journal |