Woodworker's Journal 2008-32-6, страница 21

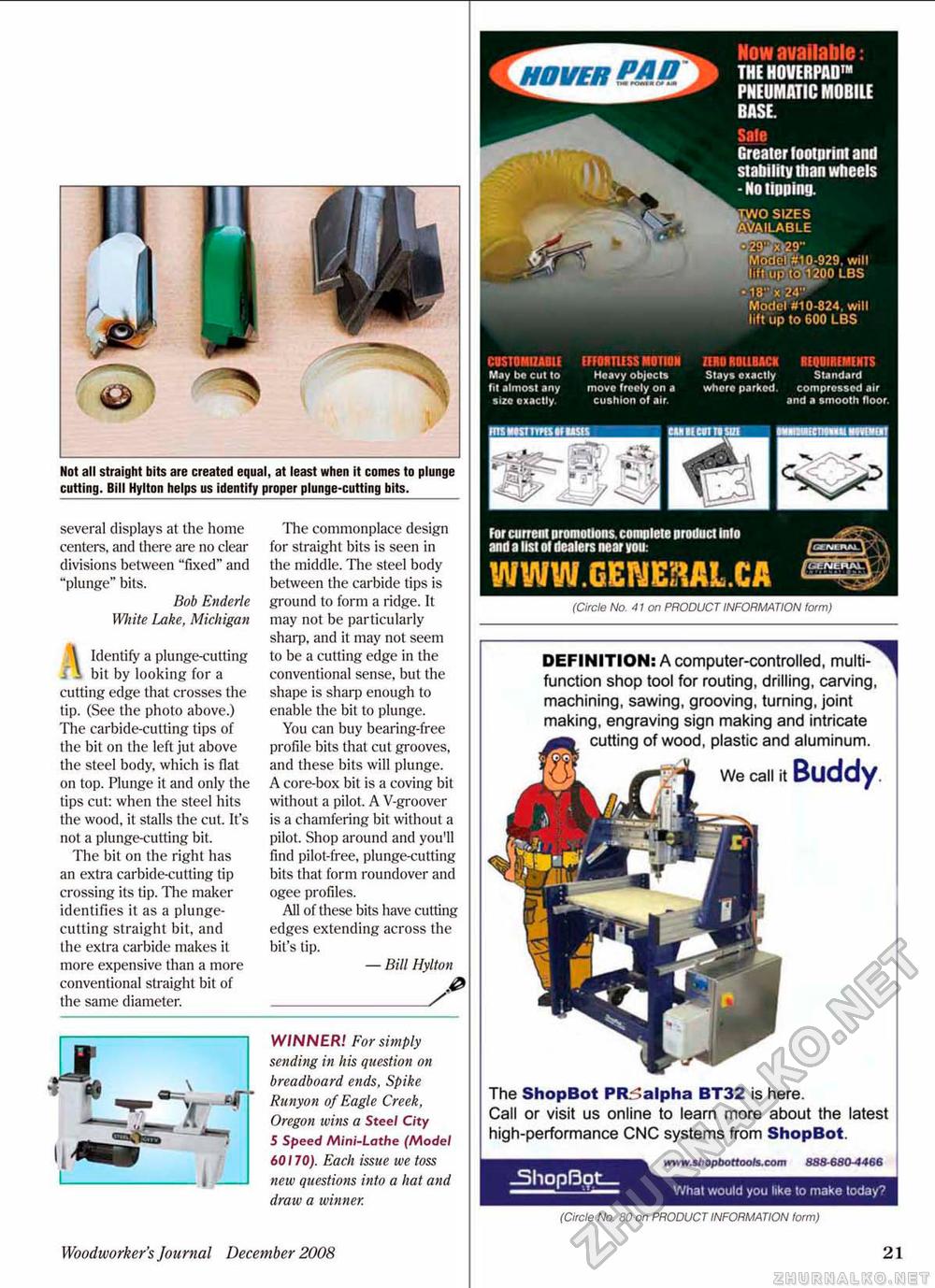

Not all straight bits are created equal, at least when it conies to plunge cutting. Bill Hylton helps us identify proper plunge-cutting bits. several displays at the home centals, and there are no clear divisions between "fixed" and "plunge" bits. Bob Enderie White Lake, Michigan \ identify a plunge-cutting - ' bit by looking for a cutting edge that crosses the tip. (See the photo above.) The carbide-cutting tips of the bit on the left jut above the steel body, which is flat on top. Plunge it and only the tips cut: when the steel hits the wood, it stalls the cut. It's not a plunge-cutting bit. The bit on the right has an extra carbide-cutting tip crossing its tip. The maker identifies it as a plunge-cutting straight bit, and the extra carbide makes it more expensive than a more conventional straight bit of the same diameter. The commonplace design for straight bits is seen in the middle. The steel body between the carbide tips is ground to form a ridge. It may not be particularly sharp, and it may not seem to be a cutting edge in the conventional sense, but the shape is sharp enough to enable the bit to plunge. You can buy bearing-free profile bits that cut grooves, and these bits will plunge. A core-box bit is a coving bit without a pilot. A V-groover is a chamfering bit without a pilot Shop around and you'll find pilot-free, plunge-cutting bits that form roundover and ogee pro files. All of these bits have cutting edges extending across the bit's lip. — Bill Hylton _ WINNER! For simply sending in his question on breadboard ends, Spike Runyon of Eagle Creek. Oregon wins a Steel City S Speed Mini-Lathe (Model 60170). Each issue we toss new questions into a hat and draw a winner. (Circle No. 41 on PRODUCT INFORMATION form) The ShopBot PR 'alpha BT32 is here. Call or visit us online to learn more about the latest high-performance CNC systems from ShopBot. _5hopf3ot_ tvww.s/ropftoftoofs, com 888-68CM466 What would you like to make today? (Circle No. 80 on PRODUCT INFORMATION lorm) Greater faotprinl and stability man wheels -No tipping. nyvo sizes 'available Model #10-824, will lift up to 600 LBS COSTDKtZABIf May be cm to M almost any size exactly. EHOftntSS MOTION HAD R011BACK Heavy objects Stays exactly move freely on a whero parked, cushion of air. REOUIRt MINTS Standard compressed ait and a smooth floor. For current promotions complete product Inlo and a list ol dealers near von DEFINITION: A computer-controlled, multifunction shop tool for routing, drilling, carving, machining, sawing, grooving, turning, joint making, engraving sign making and intricate cutting of wood, plastic and aluminum. We call it Woodworker's Journal December 2008 21 |