Woodworker's Journal 2010-34-1, страница 14

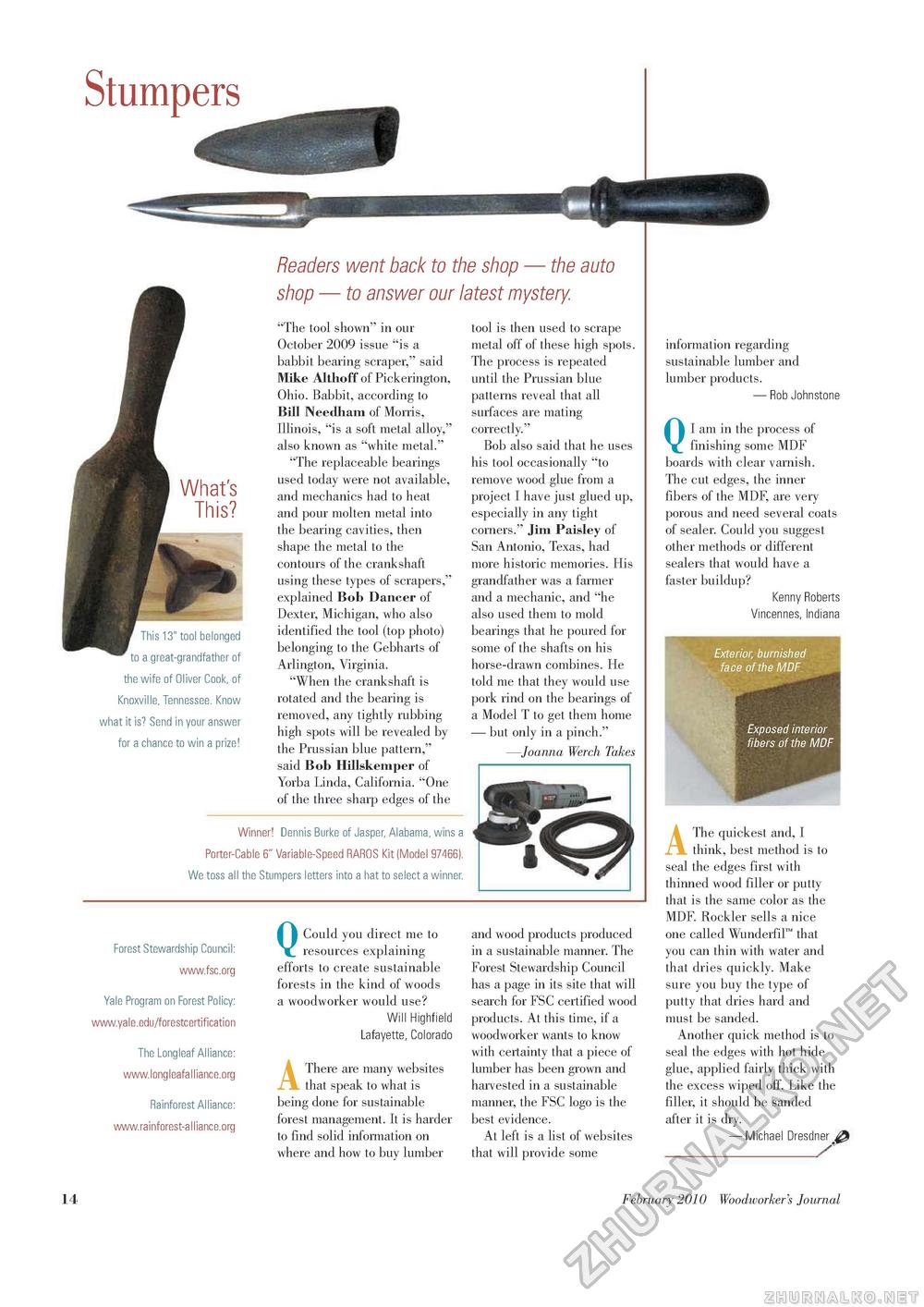

Stumpers What's This? This 13" tool belonged to a great-grandfather of the wife of Oliver Cook, of Knoxville, Tennessee. Know what it is? Send in your answer for a chance to win a prize! Readers went back to the shop — the auto shop — to answer our latest mystery. "The tool shown" in our October 2009 issue "is a babbit bearing scraper," said Mike Althoff of Pickerington, Ohio. Babbit, according to Bill Needham of Morris, Illinois, "is a soft metal alloy," also known as "white metal." "The replaceable bearings used today were not available, and mechanics had to heat and pour molten metal into the bearing cavities, then shape the metal to the contours of the crankshaft using these types of scrapers," explained Bob Dancer of Dexter, Michigan, who also identified the tool (top photo) belonging to the Gebharts of Arlington, Virginia. "When the crankshaft is rotated and the bearing is removed, any tightly rubbing high spots will be revealed by the Prussian blue pattern," said Bob Hillskemper of Yorba Linda, California. "One of the three sharp edges of the Winner! Dennis Burke of Jasper, Alabama, wins a Porter-Cable 6" Variable-Speed RAROS Kit (Model 97466). We toss all the Stumpers letters into a hat to select a winner. tool is then used to scrape metal off of these high spots. The process is repeated until the Prussian blue patterns reveal that all surfaces are mating correctly." Bob also said that he uses his tool occasionally "to remove wood glue from a project I have just glued up, especially in any tight corners." Jim Paisley of San Antonio, Texas, had more historic memories. His grandfather was a farmer and a mechanic, and "he also used them to mold bearings that he poured for some of the shafts on his horse-drawn combines. He told me that they would use pork rind on the bearings of a Model T to get them home — but only in a pinch." —Joanna Werch Takes Forest Stewardship Council: www.fsc.org Yale Program on Forest Policy: www.yale.edu/forestcertification The Longleaf Alliance: www.longleafalliance.org Rainforest Alliance: www.rainforest-alliance.org Q Could you direct me to resources explaining efforts to create sustainable forests in the kind of woods a woodworker would use? Will Highfield Lafayette, Colorado A There are many websites that speak to what is being done for sustainable forest management. It is harder to find solid information on where and how to buy lumber and wood products produced in a sustainable manner. The Forest Stewardship Council has a page in its site that will search for FSC certified wood products. At this time, if a woodworker wants to know with certainty that a piece of lumber has been grown and harvested in a sustainable manner, the FSC logo is the best evidence. At left is a list of websites that will provide some information regarding sustainable lumber and lumber products. — Rob Johnstone QI am in the process of finishing some MDF boards with clear varnish. The cut edges, the inner fibers of the MDF, are very porous and need several coats of sealer. Could you suggest other methods or different sealers that would have a faster buildup? Kenny Roberts Vincennes, Indiana Exterior, burnished face of the MDF Exposed interior fibers of the MDF A The quickest and, I think, best method is to seal the edges first with thinned wood filler or putty that is the same color as the MDF. Rockler sells a nice one called Wunderfil™ that you can thin with water and that dries quickly. Make sure you buy the type of putty that dries hard and must be sanded. Another quick method is to seal the edges with hot hide glue, applied fairly thick with the excess wiped off. Like the filler, it should be sanded after it is dry. — Michael Dresdner^ 14 February 2010 Woodworker's Journal |