Woodworker's Journal 2010-34-1, страница 18

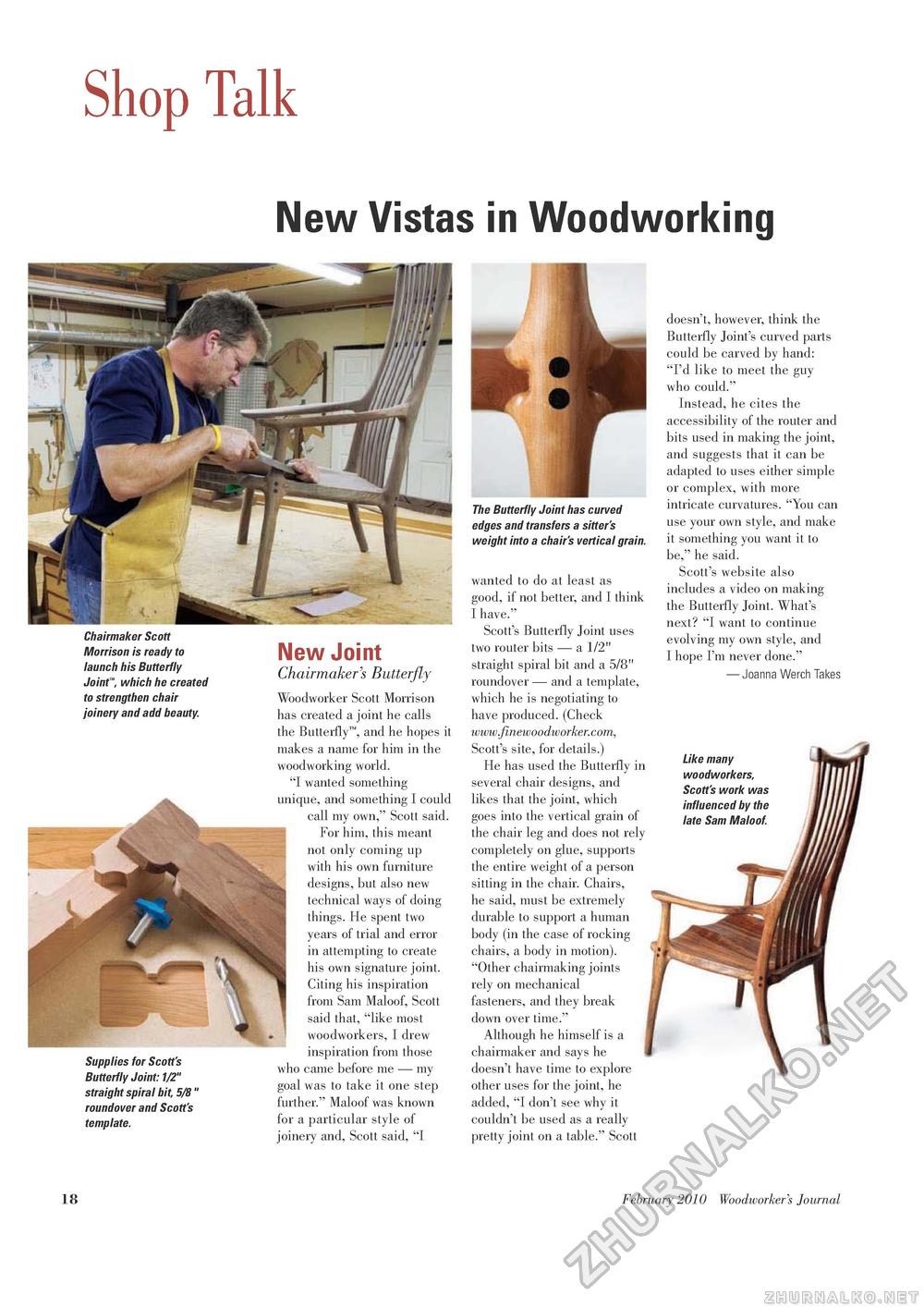

Shop Talk New Vistas in Woodworking Chairmaker Scott Morrison is ready to launch his Butterfly Joint™, which he created to strengthen chair joinery and add beauty. Supplies for Scott's Butterfly Joint:1/2" straight spiral bit, 5/8 " roundover and Scott's template. New Joint Chairmakers Butterfly Woodworker Scott Morrison has created a joint he calls the Butterfly™, and he hopes it makes a name for him in the woodworking world. "I wanted something unique, and something I could call my own," Scott said. For him, this meant not only coming up with his own furniture designs, but also new technical ways of doing things. He spent two years of trial and error in attempting to create his own signature joint. Citing his inspiration from Sam Maloof, Scott said that, "like most woodworkers, I drew inspiration from those who came before me — my goal was to take it one step further." Maloof was known for a particular style of joinery and, Scott said, "I The Butterfly Joint has curved edges and transfers a sitter's weight into a chair's vertical grain. wanted to do at least as good, if not better, and I think I have." Scott's Butterfly Joint uses two router bits — a 1/2" straight spiral bit and a 5/8" roundover — and a template, which he is negotiating to have produced. (Check www.finewoodworker.com, Scott's site, for details.) He has used the Butterfly in several chair designs, and likes that the joint, which goes into the vertical grain of the chair leg and does not rely completely on glue, supports the entire weight of a person sitting in the chair. Chairs, he said, must be extremely durable to support a human body (in the case of rocking chairs, a body in motion). "Other chairmaking joints rely on mechanical fasteners, and they break down over time." Although he himself is a chairmaker and says he doesn't have time to explore other uses for the joint, he added, "I don't see why it couldn't be used as a really pretty joint on a table." Scott doesn't, however, think the Butterfly Joint's curved parts could be carved by hand: "I'd like to meet the guy who could." Instead, he cites the accessibility of the router and bits used in making the joint, and suggests that it can be adapted to uses either simple or complex, with more intricate curvatures. "You can use your own style, and make it something you want it to be," he said. Scott's website also includes a video on making the Butterfly Joint. What's next? "I want to continue evolving my own style, and I hope I'm never done." — Joanna Werch Takes Like many woodworkers, Scott's work was influenced by the late Sam Maloof. 18 February 2010 Woodworker's Journal |