Woodworker's Journal 2010-34-2, страница 63

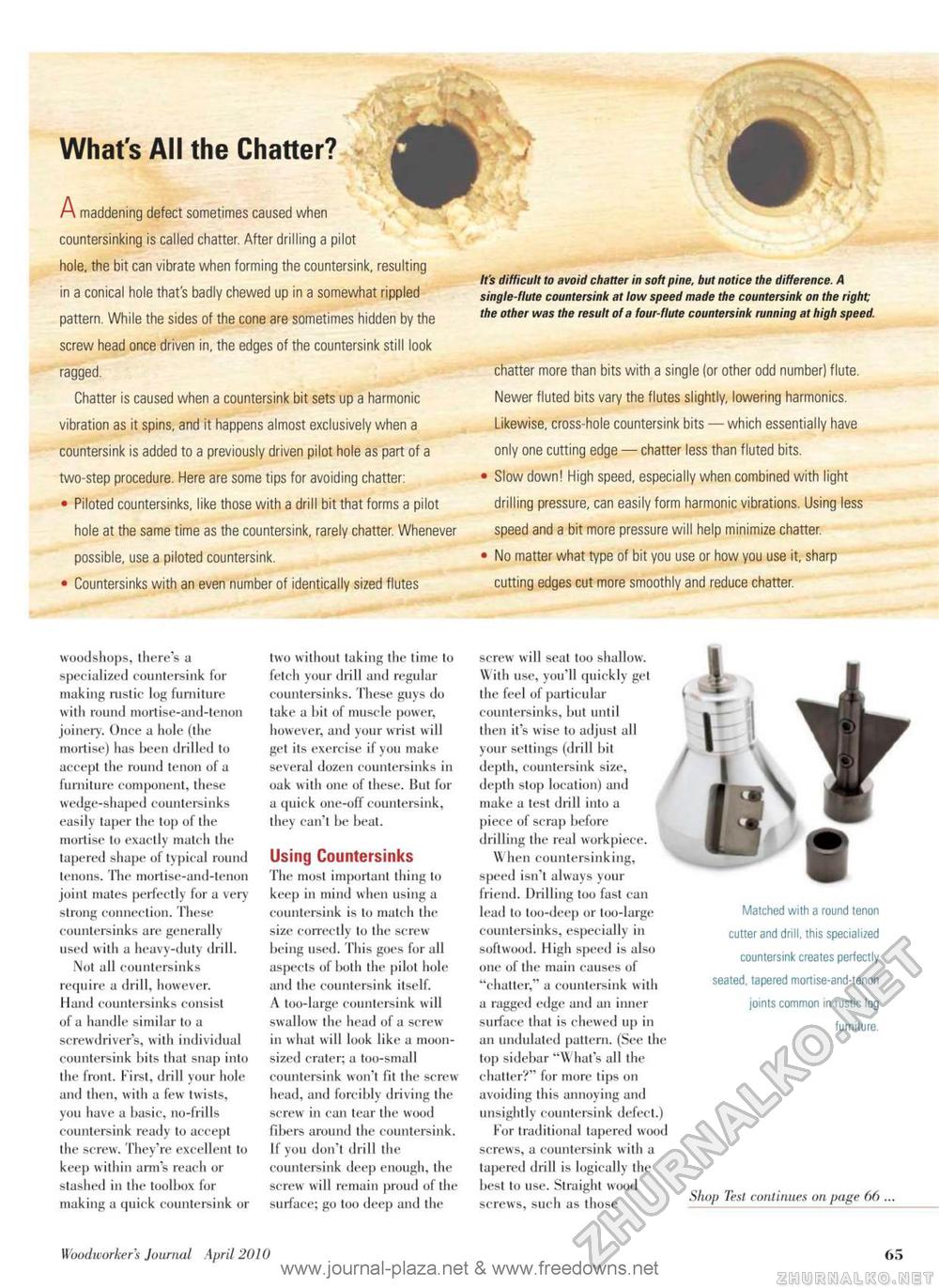

What's All the Chatter? A maddening defect sometimes caused when countersinking is called chatter. After drilling a pilot hole, the bit can vibrate when forming the countersink, resulting in a conical hole that's badly chewed up in a somewhat rippled pattern. While the sides of the cone are sometimes hidden by the screw head once driven in, the edges of the countersink still look ragged. Chatter is caused when a countersink bit sets up a harmonic vibration as it spins, and it happens almost exclusively when a countersink is added to a previously driven pilot hole as part of a two-step procedure. Here are some tips for avoiding chatter: • Piloted countersinks, like those with a drill bit that forms a pilot hole at the same time as the countersink, rarely chatter. Whenever possible, use a piloted countersink. • Countersinks with an even number of identically sized flutes It's difficult to avoid chatter in soft pine, but notice the difference. A single-flute countersink at low speed made the countersink on the right the other was the result of a four-flute countersink running at high speed. chatter more than bits with a single (or other odd number) flute. Newer fluted bits vary the flutes slightly, lowering harmonics. Likewise, cross-hole countersink bits — which essentially have only one cutting edge — chatter less than fluted bits. • Slow down! High speed, especially when combined with light drilling pressure, can easily form harmonic vibrations. Using less speed and a bit more pressure will help minimize chatter. • No matter what type of bit you use or how you use it, sharp cutting edges cut more smoothly and reduce chatter. woodshops, there's a spec ialized countersink for making rustic log furniture with round mortise-and-tenon joinery. Once a hole (the mortise) has been drilled to accept the round tenon of a furniture component, these wedge-shaped countersinks easily taper the top of the mortise to exactly match the tapered shape of typical round tenons. The mortise-and-tenon joint mates perfectly for a very strong connection. These countersinks are generally used with a heavy-duty drill. Not all countersinks require a drill, however. Hand countersinks consist of a handle similar lo a screwdriver's, with individual countersink bits that snap into the front. First, drill your hole and then, with a few twists, you have a basic, no-frills countersink ready to accept the screw. They're excellent lo keep within arm's reach or stashed in the toolbox for making a quick countersink or two without taking the time to fetch your drill and regular countersinks. These guys do take a hit of muscle power, however, and your wrist will get its exercise if you make several dozen countersinks in oak with one of these. But for a quick one-off countersink, they can't be beat. Using Countersinks The most important thing lo keep in mind when using a countersink is lo malch the size correctly lo the screw being used. This goes for all aspects of bolh the pilot hole and the countersink itself. A too-large countersink will swallow the head of a screw in what will look like a moon-sized crater; a too-small countersink won't fit the screw head, and forcibly driving the screw in can tear the wood fibers around the countersink. If you don't drill the countersink deep enough, the screw will remain proud of the surface; go too deep and the screw will seal too shallow. With use, you'll quickly gel the feel of particular countersinks, but until then it's wise to adjust all your settings (drill bit depth, countersink size, depth stop location) and make a test drill into a piece of scrap before drilling the real workpiece. When countersinking, speed isn't always your friend. Drilling too fast can lead lo loo-deep or too-large countersinks, especially in softwood. High speed is also one of the main causes of "chatter," a countersink with a ragged edge and an inner surface that is chewed up in an undulated pattern. (See the lop sidebar "What's all the chatter?" for more tips on avoiding this annoying and unsightly countersink defect.) For traditional tapered wood screws, a countersink with a tapered drill is logically the best to use. Straight wood screws, such as those ! Matched with a round tenon cutter and drill, this specialized countersink creates perfectly seated, tapered mortise-and-tenon joints common in rustic log furniture. Shop Test continues on page 66 . Woodworker's Journal April 2010 www.journal-plaza.net & www.freedowns.net it |