Woodworker's Journal fall-2008, страница 19

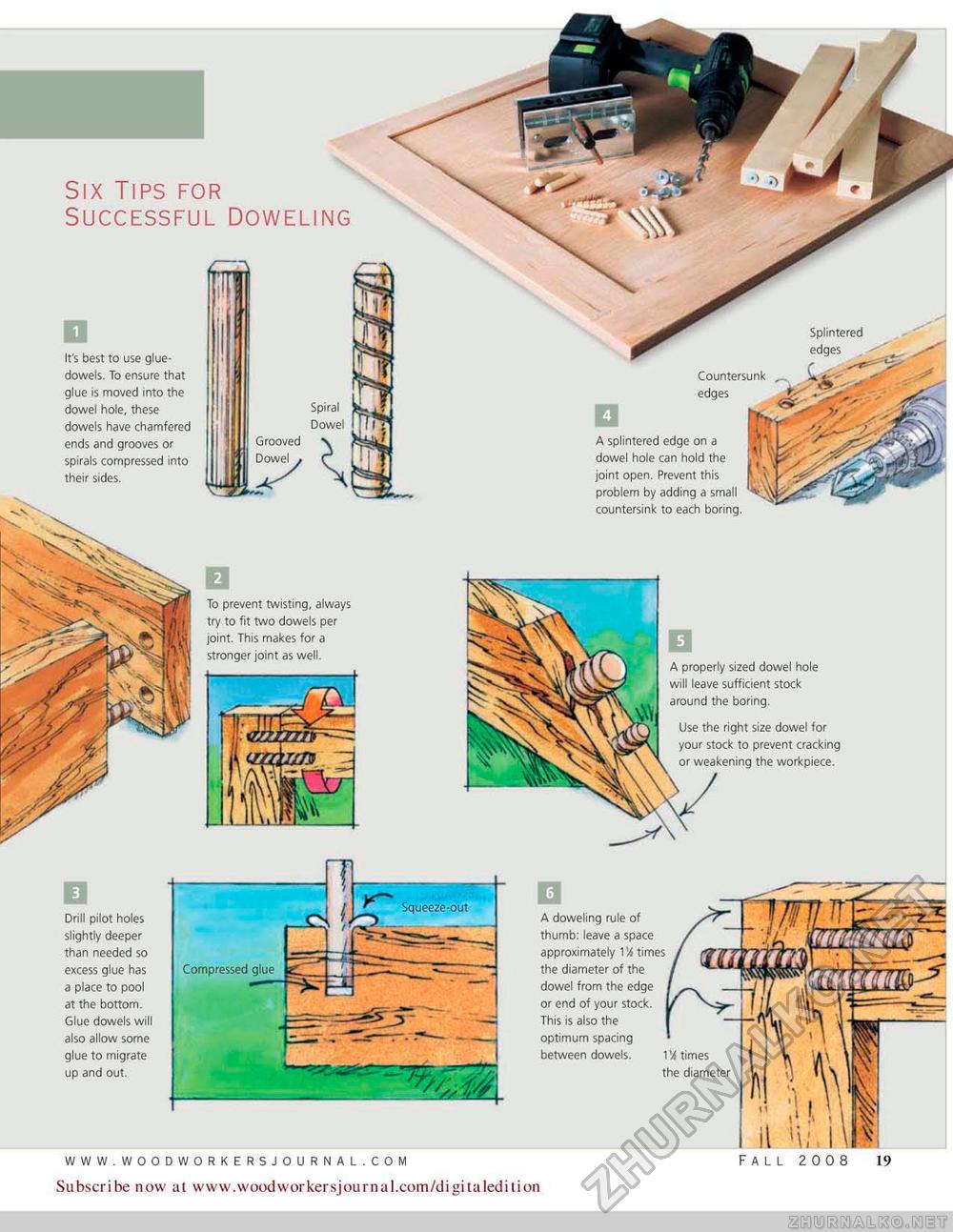

Six Tips for Successful Doweling Spiintered edges It's best to use glue-dowels. To ensure that glue is moved into the dowel hole, these dowels have chamfered ends and grooves or spirals compressed into their sides. Countersunk edges Spiral Dowel Grooved Dowel y A splintered edge on a dowel hole can hold the joint open. Prevent this problem by adding a small countersink to each boring. To prevent twisting, always try to fit two dowels per joint. This makes for a stronger joint as well. A properly sized dowel hole will leave sufficient stock around the boring. Use the right size dowel for your stock to prevent cracking or weakening the workpiece. Drill pilot holes slightly deeper than needed so excess glue has a place to pool at the bottom. Glue dowels will also allow some glue to migrate up and out. A doweling rule of thumb: leave a space approximately 1 \i times the diameter of the dowel from the edge or end of your stock. This is also the optimum spacing between dowels. 1'i times the diameter Subscribe now at www.wpodwoirkersjournal.com/digitaledition |