Woodworker's Journal fall-2009, страница 60

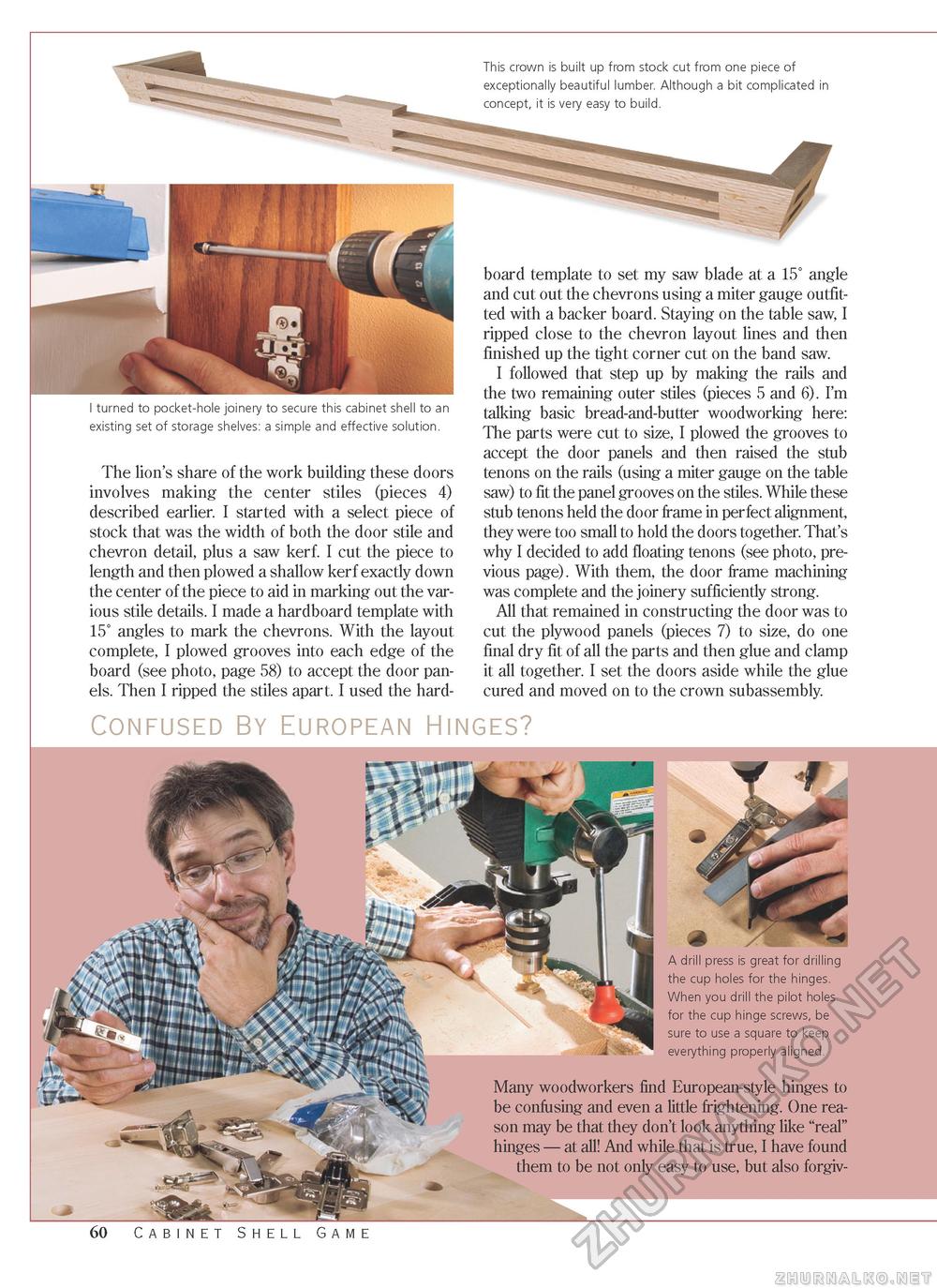

This crown is built up from stock cut from one piece of exceptionally beautiful lumber. Although a bit complicated in concept, it is very easy to build. / I turned to pocket-hole joinery to secure this cabinet shell to an existing set of storage shelves: a simple and effective solution. The lion's share of the work building these doors involves making the center stiles (pieces 4) described earlier. I started with a select piece of stock that was the width of both the door stile and chevron detail, plus a saw kerf. I cut the piece to length and then plowed a shallow kerf exactly down the center of the piece to aid in marking out the various stile details. I made a hardboard template with 15° angles to mark the chevrons. With the layout complete, I plowed grooves into each edge of the board (see photo, page 58) to accept the door panels. Then I ripped the stiles apart. I used the hard- f board template to set my saw blade at a 15° angle and cut out the chevrons using a miter gauge outfitted with a backer board. Staying on the table saw, I ripped close to the chevron layout lines and then finished up the tight corner cut on the band saw. I followed that step up by making the rails and the two remaining outer stiles (pieces 5 and 6). I'm talking basic bread-and-butter woodworking here: The parts were cut to size, I plowed the grooves to accept the door panels and then raised the stub tenons on the rails (using a miter gauge on the table saw) to fit the panel grooves on the stiles. While these stub tenons held the door frame in perfect alignment, they were too small to hold the doors together. That's why I decided to add floating tenons (see photo, previous page). With them, the door frame machining was complete and the joinery sufficiently strong. All that remained in constructing the door was to cut the plywood panels (pieces 7) to size, do one final dry fit of all the parts and then glue and clamp it all together. I set the doors aside while the glue cured and moved on to the crown subassembly. Confused By European Hinges? A drill press is great for drilling the cup holes for the hinges. When you drill the pilot holes for the cup hinge screws, be sure to use a square to keep everything properly aligned. Many woodworkers find European-style hinges to be confusing and even a little frightening. One reason may be that they don't look anything like "real" hinges — at all! And while that is true, I have found them to be not only easy to use, but also forgiv- 60 Cabinet Shell Game |