Woodworker's Journal fall-2010, страница 33

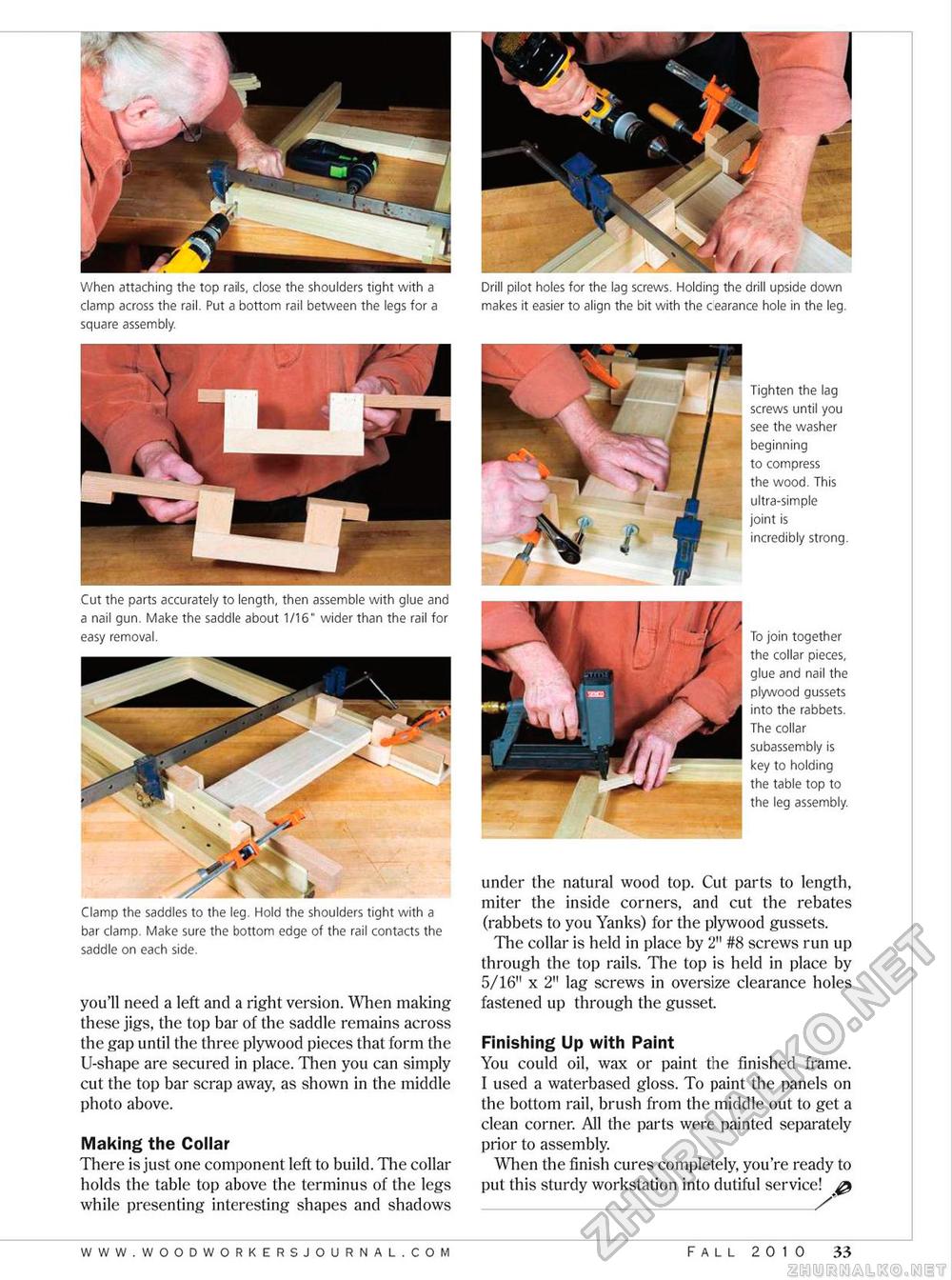

When attaching the top rails, close the shoulders tight with a clamp across the rail. Put a bottom rail between the legs for a square assembly. Cut the parts accurately to length, then assemble with glue and a nail gun. Make the saddle about 1/16" wider than the rail for easy removal. Clamp the saddles to the leg. Hold the shoulders tight with a bar clamp. Make sure the bottom edge of the rail contacts the saddle on each side. you'll need a left and a right version. When making these jigs, the top bar of the saddle remains across the gap until the three plywood pieces that form the U-shape are secured in place. Then you can simply cut the top bar scrap away, as shown in the middle photo above. Making the Collar There is just one component left to build. The collar holds the table top above the terminus of the legs while presenting interesting shapes and shadows Drill pilot holes for the lag screws. Holding the drill upside down makes it easier to align the bit with the cearance hole in the leg. Tighten the lag screws until you see the washer beginning to compress the wood. This ultra-simple joint is incredibly strong. To join together the collar pieces, glue and nail the plywood gussets into the rabbets. The collar subassembly is key to holding the table top to the leg assembly. under the natural wood top. Cut parts to length, miter the inside corners, and cut the rebates (rabbets to you Yanks) for the plywood gussets. The collar is held in place by 2" #8 screws run up through the top rails. The top is held in place by 5/16" x 2" lag screws in oversize clearance holes fastened up through the gusset. Finishing Up with Paint You could oil, wax or paint the finished frame. I used a waterbased gloss. To paint the panels on the bottom rail, brush from the middle out to get a clean corner. All the parts were painted separately prior to assembly. When the finish cures completely, you're ready to put this sturdy workstation into dutiful service! ^ Fall 2010 33 |