Woodworker's Journal fall-2010, страница 38

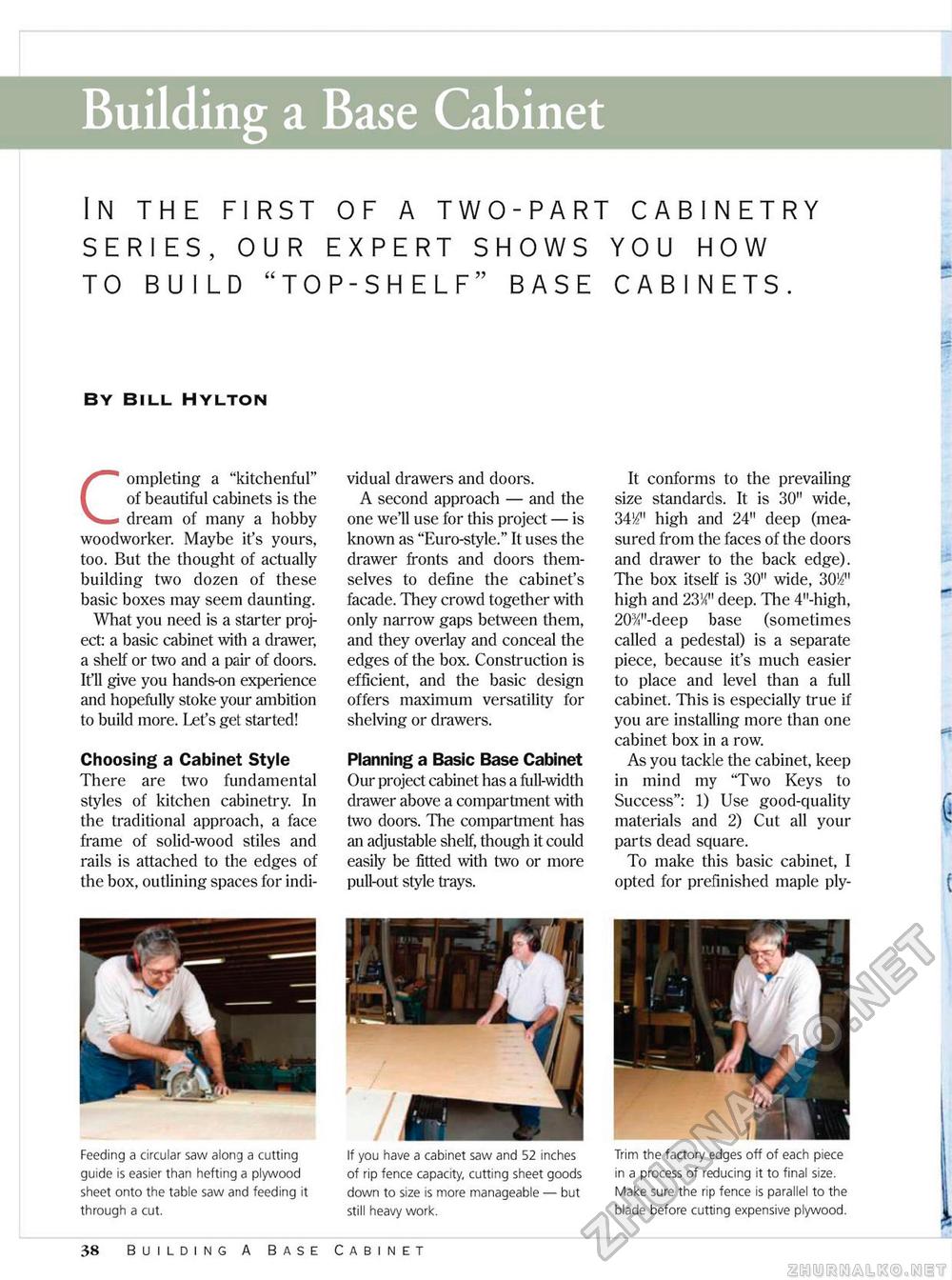

Building a Base Cabinet In the first of a two-part cabinetry series, our expert shows you how to build "top-shelf" base cabinets. BY BILL HYLTON Completing a "kitchenful" of beautiful cabinets is the dream of many a hobby woodworker. Maybe it's yours, too. But the thought of actually building two dozen of these basic boxes may seem daunting. What you need is a starter project: a basic cabinet with a drawer, a shelf or two and a pair of doors. It'll give you hands-on experience and hopefully stoke your ambition to build more. Let's get started! Choosing a Cabinet Style There are two fundamental styles of kitchen cabinetry. In the traditional approach, a face frame of solid-wood stiles and rails is attached to the edges of the box, outlining spaces for indi vidual drawers and doors. A second approach — and the one we'll use for this project — is known as "Euro-style." It uses the drawer fronts and doors themselves to define the cabinet's facade. They crowd together with only narrow gaps between them, and they overlay and conceal the edges of the box. Construction is efficient, and the basic design offers maximum versatility for shelving or drawers. Planning a Basic Base Cabinet Our project cabinet has a full-width drawer above a compartment with two doors. The compartment has an adjustable shelf, though it could easily be fitted with two or more pull-out style trays. It conforms to the prevailing size standards. It is 30" wide, 34 ^ high and 24" deep (measured from the faces of the doors and drawer to the back edge). The box itself is 30" wide, 3010' high and 23tf" deep. The 4"-high, 20%"-deep base (sometimes called a pedestal) is a separate piece, because it's much easier to place and level than a full cabinet. This is especially true if you are installing more than one cabinet box in a row. As you tackle the cabinet, keep in mind my 'Two Keys to Success": 1) Use good-quality materials and 2) Cut all your parts dead square. To make this basic cabinet, I opted for prefinished maple ply- Feeding a circular saw along a cutting guide is easier than hefting a plywood sheet onto the table saw and feeding it through a cut. If you have a cabinet saw and 52 inches of rip fence capacity, cutting sheet goods down to size is more manageable — but still heavy work. Trim the factory edges off of each piece in a process of reducing it to final size. Make sure the rip fence is parallel to the blade before cutting expensive plywood. 38 Building A Base Cabinet |