Woodworker's Journal Harvest-Table, страница 5

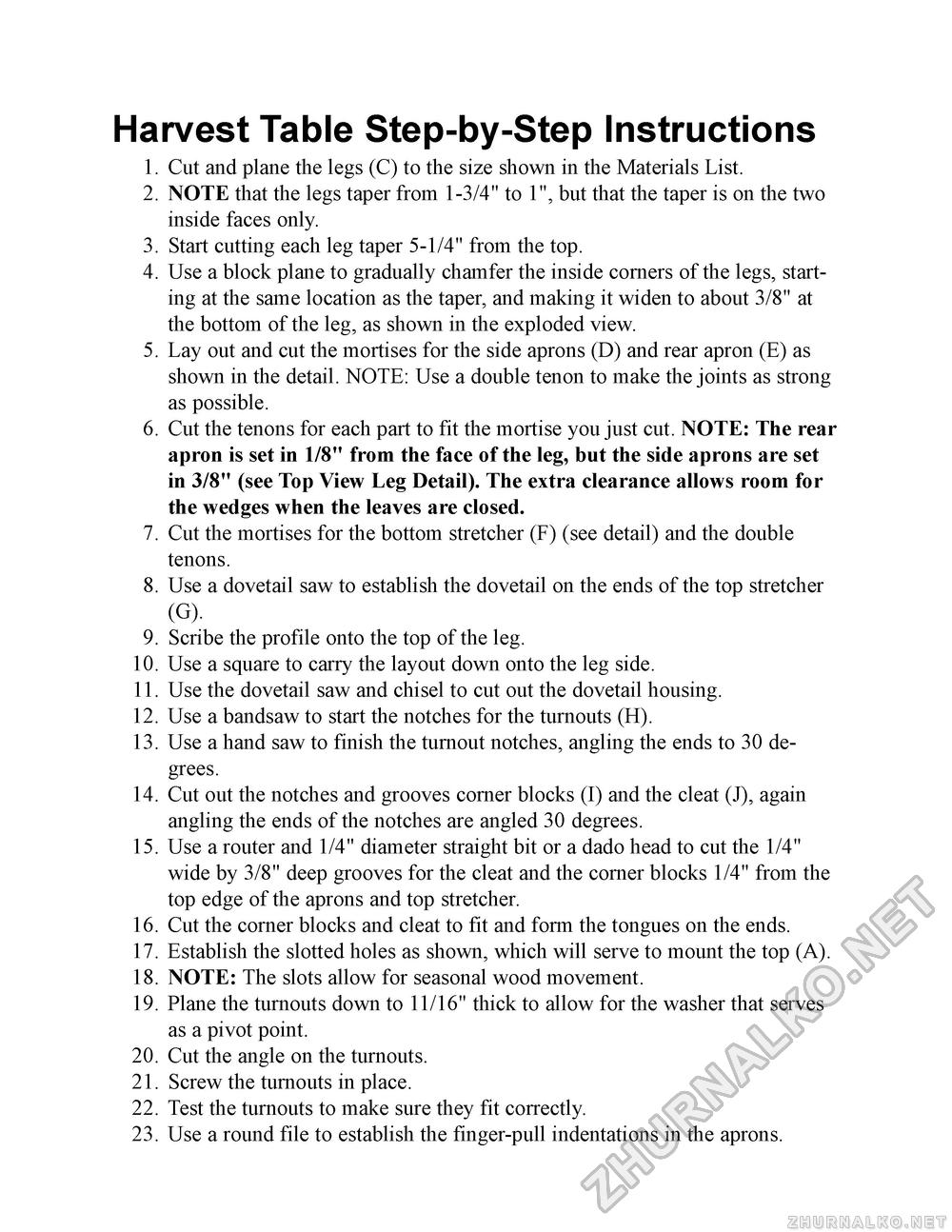

Harvest Table Step-by-Step Instructions1. Cut and plane the legs (C) to the size shown in the Materials List. 2. NOTE that the legs taper from 1-3/4" to 1", but that the taper is on the two inside faces only. 3. Start cutting each leg taper 5-1/4" from the top. 4. Use a block plane to gradually chamfer the inside corners of the legs, starting at the same location as the taper, and making it widen to about 3/8" at the bottom of the leg, as shown in the exploded view. 5. Lay out and cut the mortises for the side aprons (D) and rear apron (E) as shown in the detail. NOTE: Use a double tenon to make the joints as strong as possible. 6. Cut the tenons for each part to fit the mortise you just cut. NOTE: The rear apron is set in 1/8" from the face of the leg, but the side aprons are set in 3/8" (see Top View Leg Detail). The extra clearance allows room for the wedges when the leaves are closed. 7. Cut the mortises for the bottom stretcher (F) (see detail) and the double tenons. 8. Use a dovetail saw to establish the dovetail on the ends of the top stretcher (G). 9. Scribe the profile onto the top of the leg. 10. Use a square to carry the layout down onto the leg side. 11. Use the dovetail saw and chisel to cut out the dovetail housing. 12. Use a bandsaw to start the notches for the turnouts (H). 13. Use a hand saw to finish the turnout notches, angling the ends to 30 degrees. 14. Cut out the notches and grooves corner blocks (I) and the cleat (J), again angling the ends of the notches are angled 30 degrees. 15. Use a router and 1/4" diameter straight bit or a dado head to cut the 1/4" wide by 3/8" deep grooves for the cleat and the corner blocks 1/4" from the top edge of the aprons and top stretcher. 16. Cut the corner blocks and cleat to fit and form the tongues on the ends. 17. Establish the slotted holes as shown, which will serve to mount the top (A). 18. NOTE: The slots allow for seasonal wood movement. 19. Plane the turnouts down to 11/16" thick to allow for the washer that serves as a pivot point. 20. Cut the angle on the turnouts. 21. Screw the turnouts in place. 22. Test the turnouts to make sure they fit correctly. 23. Use a round file to establish the finger-pull indentations in the aprons. |