Woodworker's Journal winter-2009, страница 11

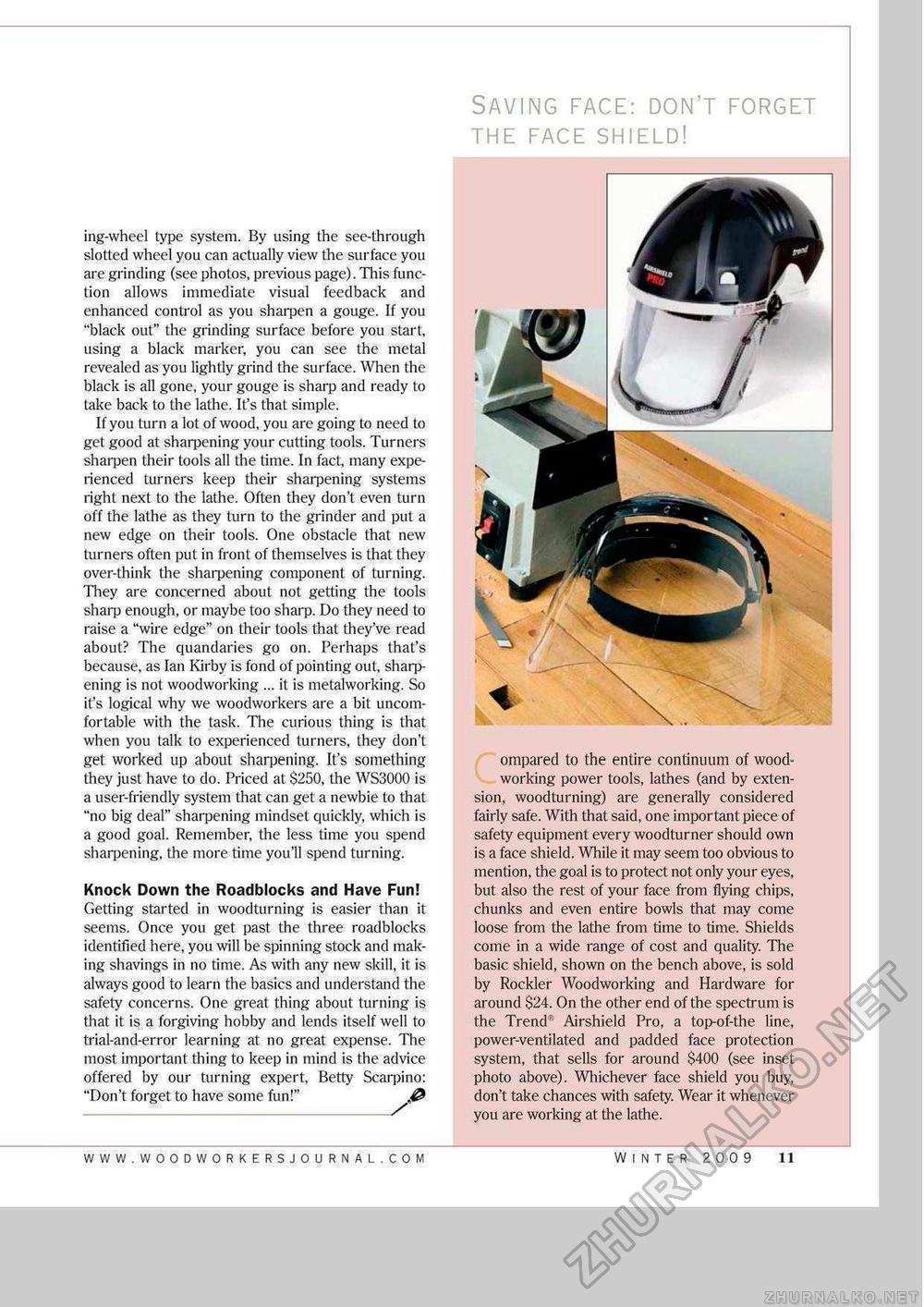

saving face: don't forget the face shield! ing-wheel type system. By using the see-through slotted wheel you can actually view the surface you are grinding (see photos, previous page). This function allows immediate visual feedback and enhanced control as you sharpen a gouge. If you "black out" the grinding surface before you start, using a black marker, you can see the metal revealed as you lightly grind the surface. When the black is all gone, your gouge is sharp and ready to take back to the lathe. It's that simple. If you turn a lot of wood, you are going to need to get good at sharpening your cutting tools. Turners sharpen their tools all the time. In fact, many experienced turners keep their sharpening systems right next to the lathe. Often they don't even turn off the lathe as they turn to the grinder and put a new edge on their tools. One obstacle that new turners often put in front of themselves is that they over-think the sharpening component of turning. They are concerned about not getting the tools sharp enough, or maybe too sharp. Do they need to raise a "wire edge" on their tools that they've read about? The quandaries go on. Perhaps that's because, as Ian Kirby is fond of pointing out, sharpening is not woodworking ... it is metalworking. So it's logical why we woodworkers are a bit uncomfortable with the task. The curious thing is that when you talk to experienced turners, they don't get worked up about sharpening. It's something they just have to do. Priced at $250, the WS3000 is a user-friendly system that can get a newbie to that "no big deal" sharpening mindset quickly, which is a good goal. Remember, the less time you spend sharpening, the more time you'll spend turning. Knock Down the Roadblocks and Have Fun! Getting started in woodturning is easier than it seems. Once you get past the three roadblocks identified here, you will be spinning stock and making shavings in no time. As with any new skill, it is always good to learn the basics and understand the safety concerns. One great thing about turning is that it is a forgiving hobby and lends itself well to trial-and-error learning at no great expense. The most important thing to keep in mind is the advice offered by our turning expert, Betty Scarpino: "Don't forget to have some fun!" \ ompared to the entire continuum of woodworking power tools, lathes (and by extension, woodturning) are generally considered fairly safe. With that said, one important piece of safety equipment every woodturner should own is a face shield. While it may seem too obvious to mention, the goal is to protect not only your eyes, but also the rest of your face from flying chips, chunks and even entire bowls that may come loose from the lathe from time to time. Shields come in a wide range of cost and quality. The basic shield, shown on the bench above, is sold by Rockier Woodworking and Hardware for around $24. On the other end of the spectrum is the Trend" Airshield Pro, a top-of-the line, power-ventilated and padded face protection system, that sells for around $400 (see inset photo above). "Whichever face shield you buy, don't take chances with safety. Wear it whenever you are working at the lathe. winter 2009 11 |