Woodworker's Journal winter-2009, страница 39

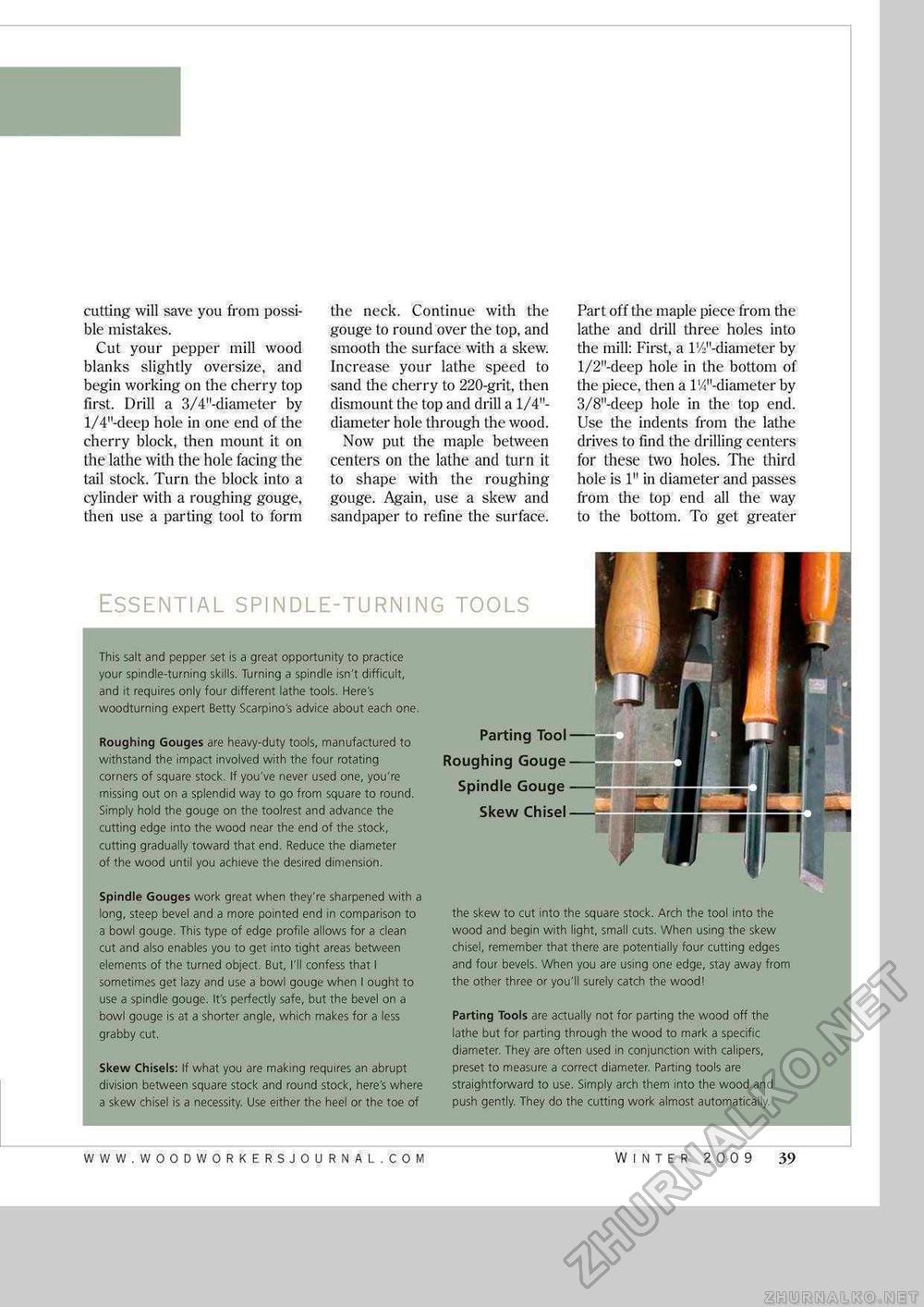

cutting will save you from possible mistakes. Cut your pepper mill wood blanks slightly oversize, and begin working on the cherry top first. Drill a 3/4"-diameter by l/4"-deep hole in one end of the cherry block, then mount it on the lathe with the hole facing the tail stock. Turn the block into a cylinder with a roughing gouge, then use a parting tool to form the neck. Continue with the gouge to round over the top, and smooth the surface with a skew. Increase your lathe speed to sand the cherry to 220-grit, then dismount the top and drill a 1/4"-diameter hole through the wood. Now put the maple between centers on the lathe and turn it to shape with the roughing gouge. Again, use a skew and sandpaper to refine the surface. Part off the maple piece from the lathe and drill three holes into the mill: First, a 1'/-"-diameter by l/2"-deep hole in the bottom of the piece, then a 1'/"-diameter by 3/8"-deep hole in the top end. Use the indents from the lathe drives to find the drilling centers for these two holes. The third hole is 1" in diameter and passes from the top end all the way to the bottom. To get greater Essential spindle-turning tools This salt and pepper set is a great opportunity to practice your spindle-turning skills. Turning a spindle isn't difficult, and it requires only four different lathe tools. Here's woodturning expert Betty Scarpino's advice about each one. Roughing Gouges are heavy-duty tools, manufactured to withstand the impact involved with the four rotating corners of square stock. If you've never used one, you're missing out on a splendid way to go from square to round. Simply hold the gouge on the toolrest and advance the cutting edge into the wood near the end of the stock, cutting gradually toward that end. Reduce the diameter of the wood until you achieve the desired dimension. Parting Tool Roughing Gouge Spindle Gouge Skew Chisel Spindle Gouges work great when they're sharpened with a long, steep bevel and a more pointed end in comparison to a bowl gouge. This type of edge profile allows for a clean cut and also enables you to get into tight areas between elements of the turned object. But, I'll confess that I sometimes get lazy and use a bowi gouge when I ought to use a spindle gouge. It's perfectly safe, but the bevel on a bowl gouge is at a shorter angle, which makes for a less grabby cut. Skew Chisels: If what you are making requires an abrupt division between square stock and round stock, here's where a skew chisel is a necessity. Use either the heel or the toe of the skew to cut into the square stock. Arch the tool into the wood and begin with light, small cuts. When using the skew chisel, remember that there are potentially four cutting edges and four bevels. When you are using one edge, stay away from the other three or you'll sureiy catch the wood! Parting Tools are actually not for parting the wood off the lathe but for parting through the wood to mark a specific diameter. They are often used in conjunction with calipers, preset to measure a correct diameter. Parting tools are straightforward to use. Simply arch them into the wood and push gently. They do the cutting work almost automatically. WINTER 2009 39 |