Woodworker's Journal winter-2009, страница 42

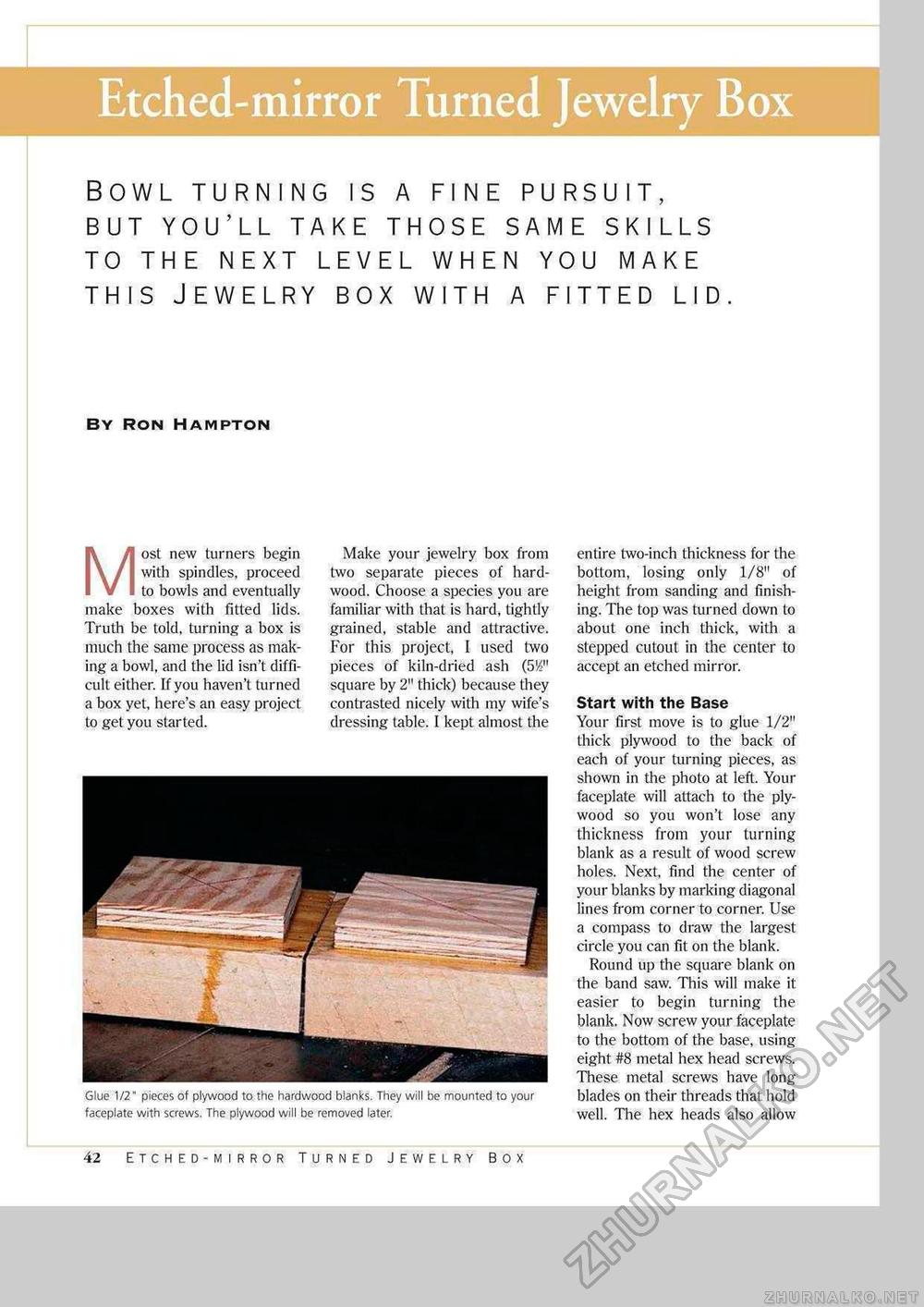

Etched-mirror Turned Jewelry Box Bowl turning is a fine pursuit, but you'll take those same skills to the next level when you make this Jewelry box with a fitted lid. By Ron Hampton Most new turners begin with spindles, proceed to bowls and eventually make boxes with fitted lids. Truth be told, turning a box is much the same process as making a bowl, and the lid isn't difficult either. If you haven't turned a box yet, here's an easy project to get you started. Make your jewelry box from two separate pieces of hardwood. Choose a species you are familiar with that is hard, tightly grained, stable and attractive. For this project, I used two pieces of kiln-dried ash square by 2" thick) because they contrasted nicely with my wife's dressing table. I kept almost the entire two-inch thickness for the bottom, losing only 1/8" of height from sanding and finishing. The top was turned clown to about one inch thick, with a stepped cutout in the center to accept an etched mirror. Start with the Base Your first move is to glue 1/2" thick plywood to the back of each of your turning pieces, as shown in the photo at left. Your faceplate will attach to the plywood so you won't lose any thickness from your turning blank as a result of wood screw holes. Next, find the center of your blanks by marking diagonal lines from corner to corner. Use a compass to draw the largest circle you can fit on the blank. Round up the square blank on the band saw. This will make it easier to begin turning the blank. Now screw your faceplate to the bottom of the base, using eight #8 metal hex head screws. These metal screws have long blades on their threads that, hold well. The hex heads also allow Glue 1/2" pieces of plywood to the hardwood blanks. They will be mounted to your faceplate with screws. The plywood will be removed later. 42 Etched-mirror Turned Jewelry Box |