Woodworker's Journal winter-2009, страница 44

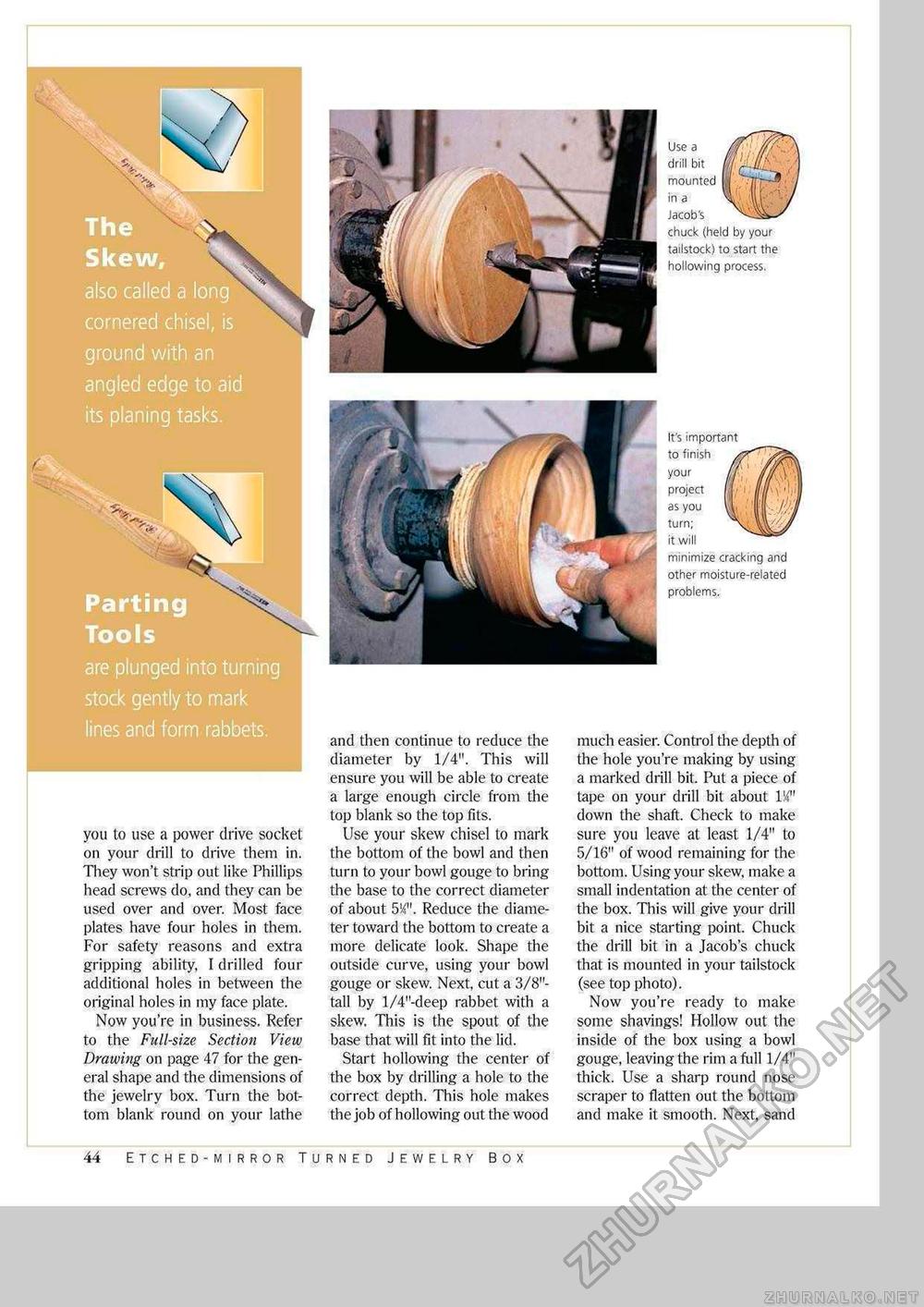

\ '<*■ also called a long cornered chisel, is ground with an angled edge to aid its planing tasks. Parting Tools are plunged into turning stock gently to mark lines and form rabbets. It's important to finish your project as you turn; it will minimize cracking and other moisture-related problems. and then continue to reduce the diameter by 1/4". This will ensure you will be able to create a large enough circle from the top blank so the top fits. Use your skew chisel to mark the bottom of the bowl and then turn to your bowl gouge to bring the base to the correct diameter of about 5!4". Reduce the diameter toward the bottom to create a more delicate look. Shape the outside curve, using your bowl gouge or skew. Next, cut a 3/8"-tall by 1/4"-deep rabbet with a skew. This is the spout of the base that will fit into the lid. Start hollowing the center of the box by drilling a hole to the correct depth. This hole makes the job of hollowing out the wood much easier. Control the depth of the hole you're making by using a marked drill bit. Put a piece of tape on your drill bit about 1!<(" down the shaft. Check to make sure you leave at least 1/4" to 5/16" of wood remaining for the bottom. Using your skew, make a small indentation at the center of the box. This will give your drill bit a nice starting point. Chuck the drill bit in a Jacob's chuck that is mounted in your tailstock (see top photo). Now you're ready to make some shavings! Hollow out the inside of the box using a bowl gouge, leaving the rim a full 1/4" thick. Use a sharp round nose scraper to flatten out the bottom and make it smooth. Next, sand you to use a power drive socket on your drill to drive them in. They won't strip out like Phillips head screws do, and they can be used over and over. Most face plates have four holes in them. For safety reasons and extra gripping ability, I drilled four additional holes in between the original holes in my face plate. Now you're in business. Refer to the Full-size Section View Drawing on page 47 for the general shape and the dimensions of the jewelry box. Turn the bottom blank round on your lathe Use a drill bit mounted in a Jacob's chuck (held by your tailstock) to start the hollowing process. 44 Etched-mirror Turned Jewelry Box |