Woodworker's Journal winter-2010, страница 12

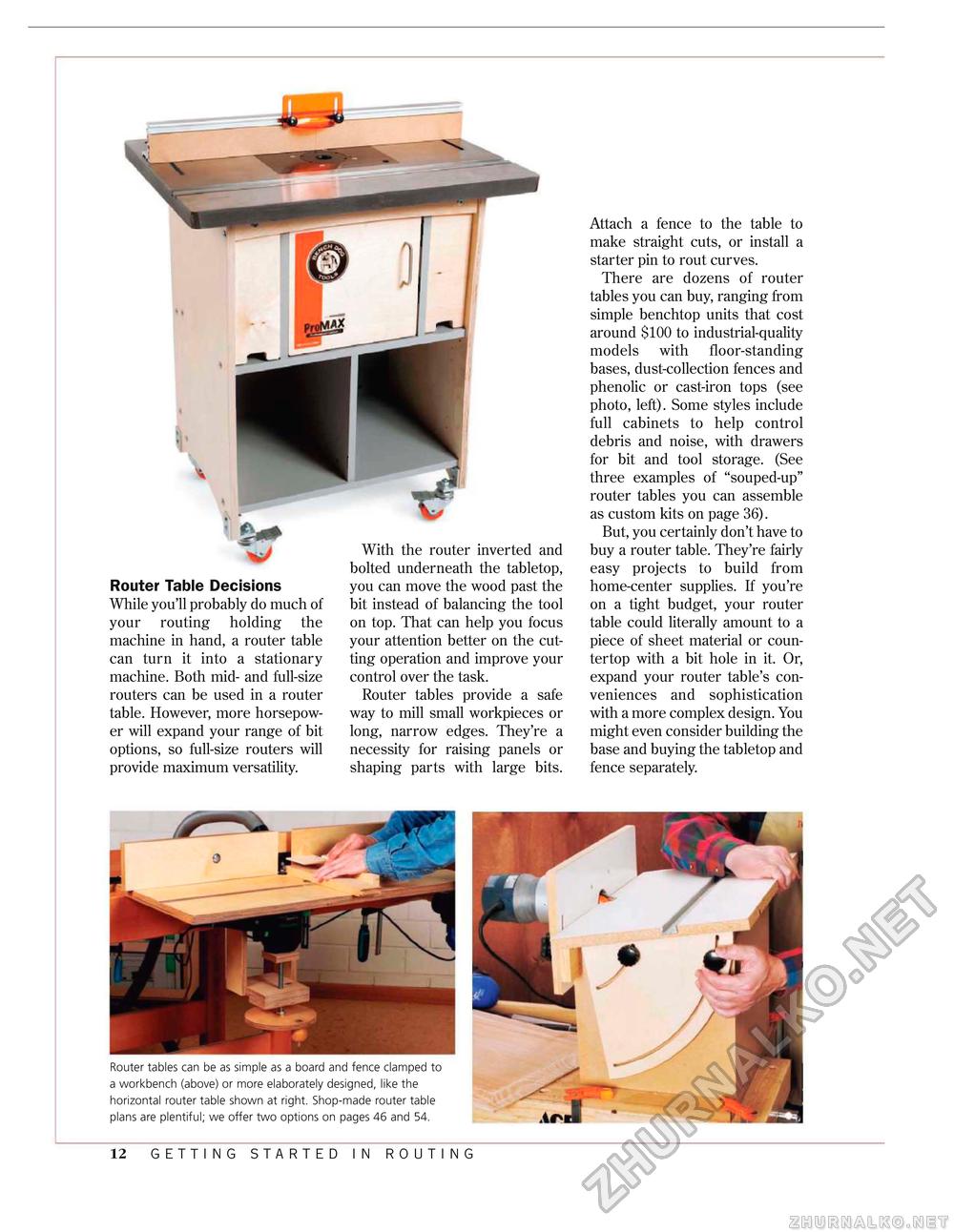

Attach a fence to the table to make straight cuts, or install a starter pin to rout curves. There are dozens of router tables you can buy, ranging from simple benchtop units that cost around $100 to industrial-quality models with floor-standing bases, dust-collection fences and phenolic or cast-iron tops (see photo, left). Some styles include full cabinets to help control debris and noise, with drawers for bit and tool storage. (See three examples of "souped-up" router tables you can assemble as custom kits on page 36). But, you certainly don't have to buy a router table. They're fairly easy projects to build from home-center supplies. If you're on a tight budget, your router table could literally amount to a piece of sheet material or coun-tertop with a bit hole in it. Or, expand your router table's conveniences and sophistication with a more complex design. You might even consider building the base and buying the tabletop and fence separately. With the router inverted and bolted underneath the tabletop, you can move the wood past the bit instead of balancing the tool on top. That can help you focus your attention better on the cutting operation and improve your control over the task. Router tables provide a safe way to mill small workpieces or long, narrow edges. They're a necessity for raising panels or shaping parts with large bits. Router Table Decisions While you'll probably do much of your routing holding the machine in hand, a router table can turn it into a stationary machine. Both mid- and full-size routers can be used in a router table. However, more horsepower will expand your range of bit options, so full-size routers will provide maximum versatility. Router tables can be as simple as a board and fence clamped to a workbench (above) or more elaborately designed, like the horizontal router table shown at right. Shop-made router table plans are plentiful; we offer two options on pages 46 and 54. 12 GETTING STARTED IN ROUTING |