Creative Woodworks & crafts 1999-11, страница 26

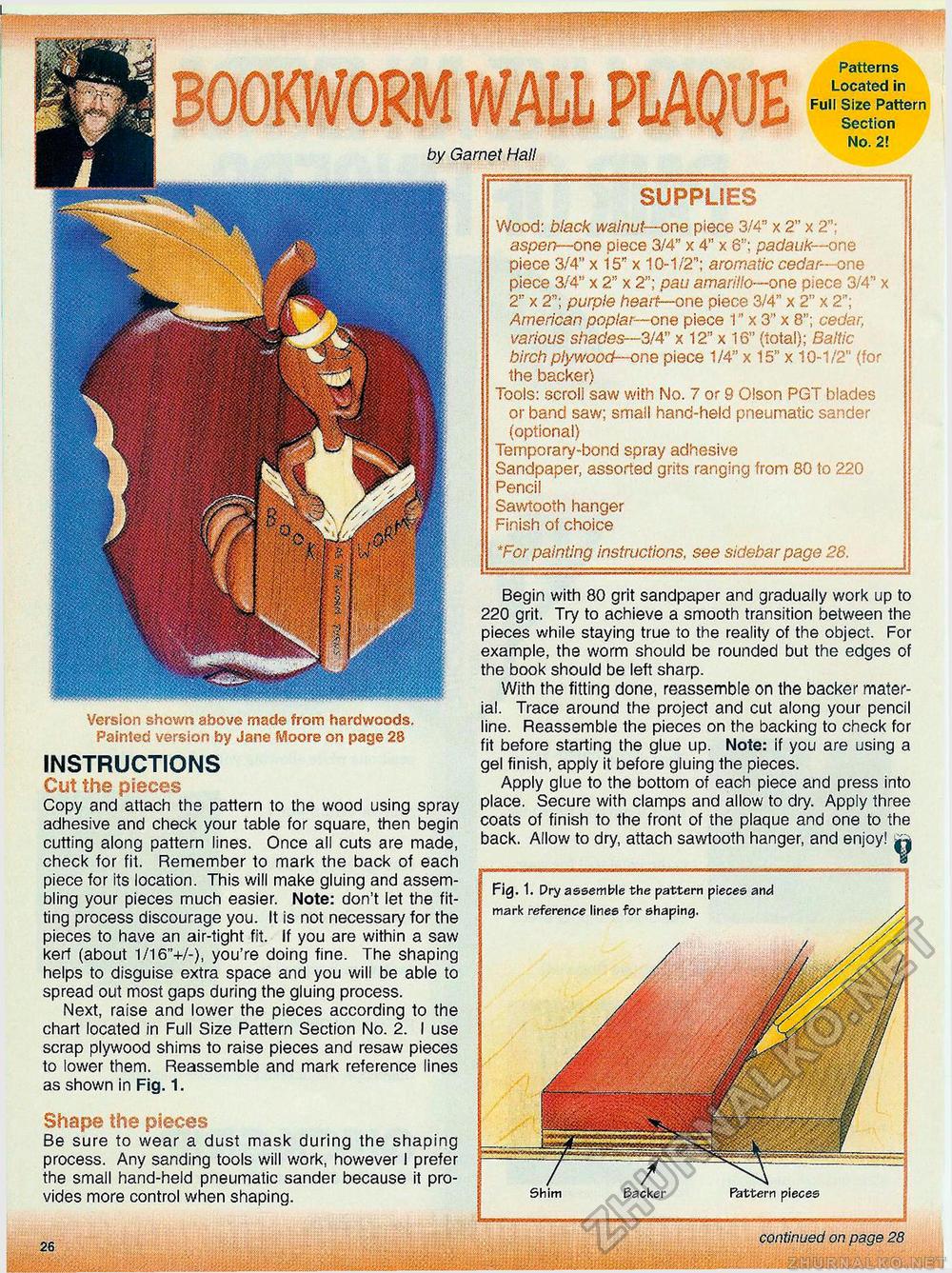

Patterns Located in Full Size Pattern Section No. 2! by Garnet Hall Wood: black walnut— one piece 3/4" x 2" x 2": aspen—one piece 3/4" x 4" x 8"; padauk— one piece 3/4" x 15" x 10-1/2"; aromatic cedar—-one piece 3/4" x 2" x 2"; pau amariilo—one piece 3/4" x 2" x 2"; purple heart— one piece 3/4" x 2" x 2"; American poplar— one piece 1" x 3" x 8"; cedar, various shades— 3/4" x 12" x 16" (total); Baltic birch plywood—one piece 1/4" x 15" x 10-1/2" (for the backer) Tools: scroll saw with No. 7 or 9 Olson PGT blades or band saw; small hand-held pneumatic sander (optional) Temporary-bond spray adhesive Sandpaper, assorted grits ranging from 80 to 220 Pencil Sawtooth hanger Finish of choice Tor painting instructions, see sidebar page 28. Begin with 80 grit sandpaper and gradually work up to 220 grit. Try to achieve a smooth transition between the pieces while staying true to the reality of the object. For example, the worm should be rounded but the edges of the book should be left sharp. With the fitting done, reassemble on the backer material. Trace around the project and cut along your pencil line. Reassemble the pieces on the backing to check for fit before starting the glue up. Note: if you are using a gel finish, apply it before gluing the pieces. Apply glue to the bottom of each piece and press into place. Secure with clamps and allow to dry. Apply three coats of finish to the front of the plaque and one to the back. Allow to dry, attach sawtooth hanger, and enjoy! gi Version shown above made from hardwoods. Painted version by Jane Moore on page 28 instructions Cut the pieces Copy and attach the pattern to the wood using spray adhesive and check your table for square, then begin cutting along pattern lines. Once all cuts are made, check for fit. Remember to mark the back of each piece for its location. This will make gluing and assembling your pieces much easier. Note: don't let the fitting process discourage you. It is not necessary for the pieces to have an air-tight fit. if you are within a saw kerf (about 1/16"+/-), you're doing fine. The shaping helps to disguise extra space and you will be able to spread out most gaps during the gluing process. Next, raise and lower the pieces according to the chart located in Full Size Pattern Section No. 2. I use scrap plywood shims to raise pieces and resaw pieces to lower them. Reassemble and mark reference lines as shown in Fig. 1. Shape the pieces Be sure to wear a dust mask during the shaping process. Any sanding tools will work, however I prefer the small hand-held pneumatic sander because it provides more control when shaping. : Fig. 1. Pry assemble the pattern pieces and { mark reference lines for shaping. Backer Shim Pattern continued on page 28 |