Creative Woodworks & crafts 2000-04, страница 14

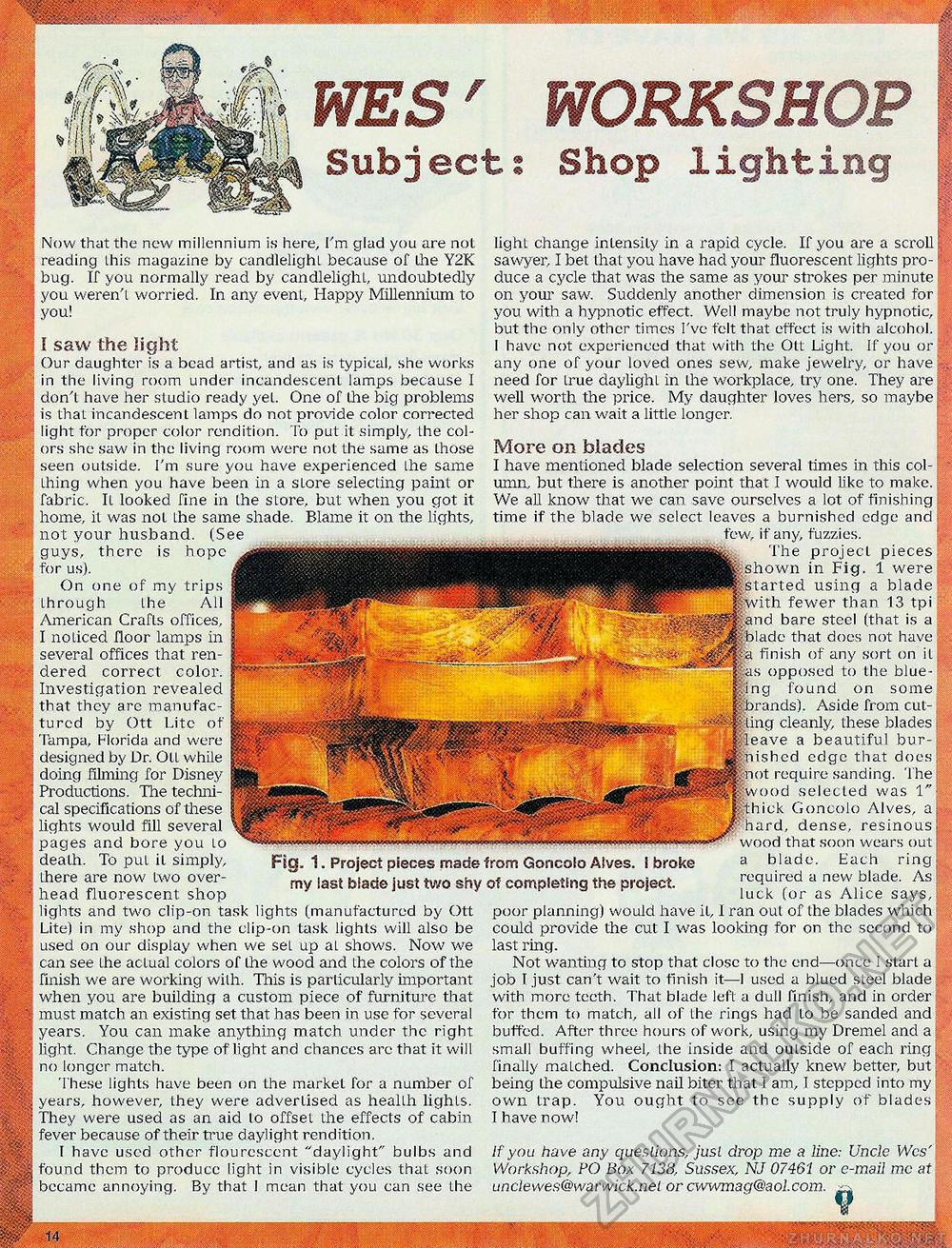

/ ■ ■ - Jms,' | Now that the new millennium is here, I'm glad you are not | reading Ihis magazine by candlelight because of the Y2K bug. If you normally read by candlelight, undoubtedly I you weren't worried. In any event, Happy Millennium to I you! E saw the light I Our daughter is a bead artist, and as is typical, she works i in the living room under incandescent lamps because I | don't have her studio ready yet. One of the big problems j is thai incandescent lamps do not provide color corrected ! light for proper color rendition. To put it simply, the col-j ors she saw in the living room were not the same as those I seen outside. I'm sure you have experienced the same | thing when you have been in a store selecting paint or fabric. It looked fine in the store, but when you got it home, it was not the same shade. Blame it on the lights, ! not your husband. (See guys, there is hope for us). On one of my trips through the All American Crafts offices, I noticed floor lamps in several offices that rendered correct color. Investigation revealed ! that they are manufactured by Ott Lite of Tampa, Florida and were designed by Dr. Ott while doing filming for Disney Productions. The technical specifications of these lights would fill several pages and bore you 10 death. To put it simply, there are now two overhead fluorescent shop lights and two clip-on task lights (manufactured by Ott Lite) in my shop and the clip-on task lights will also be used on our display when we set up at shows. Now we can see the actual colors of the wood and the colors of the finish we are working with. This is particularly important when you are building a custom piece of furniture that must match an existing set that has been in use for several years. You can make anything match under the right light. Change the type of light and chances are that it will no longer match. These lights have been on the market for a number of years, however, they were advertised as health lights. They were used as an aid to offset the effects of cabin fever because of their true daylight rendition. I have used other flourescent "daylight" bulbs and found them to produce light in visible cycles that soon became annoying. By that I mean that you can see the Fig. 1. Project pieces made from Goncoto Alves. I broke my last blade just two shy of completing the project light change intensity in a rapid cycle. If you are a scroll sawyer, I bet that you have had your fluorescent lights pro- • duce a cycle that was the same as your strokes per minute j on your saw. Suddenly another dimension is created for : you with a hypnotic effect. Well maybe not truly hypnotic, r»| but the only other times I've felt that effect is with alcohol. I have not experienced that with the Ott Light. If you or any one of your loved ones sew, make jewelry, or have need for true daylight in the workplace, try one. They are | well worth the price. My daughter loves hers, so maybe p| her shop can wait a little longer. More on blades I have mentioned blade selection several times in this col- • umn, but there is another point that I would like to make. |. We all know that we can save ourselves a lot of finishing time if the blade we select leaves a burnished edge and few, if any, fuzzies. The project pieces a Ishown in Fig. 1 were I1 started using a blade with fewer than 13 tpi .and bare steel (that is a ; |blade that does not have M |a finish of any sort on it: ;as opposed to the blue- 'f iing found on some rands). Aside from cutting cleanly, these blades: 1 peave a beautiful burnished edge that does riot require sanding, 'the: ; wood selected was 1" rthick Goncolo Alves, a<J 'hard, dense, resinous j wood that soon wears out | f a blade. Each ring;, required a new blade. As luck (or as Alice says, poor planning) would have it, I ran out of the blades which could provide the cut I was looking for on the second to\ last ring. Not wanting to stop that close to the end—once I start a | job I just can't wait to finish it—1 used a blued steel blade; with more teeth. That blade left a dull finish, and in order ; for them to match, all of the rings had to be sanded and buffed. After three hours of work, using my Dremel and a small buffing wheel, the inside and outside of each ring: finally maLched. Conclusion: I actually knew better, but being the compulsive nail biter that I am, T stepped into my own trap. You ought to see the supply of blades I have now! If you have any questions, jusl drop me a line: Uncle Wcs' ; Workshop>, PO Box 7138, Sussex, NJ 07461 or c-maii mc at unclewes@warwick.nel or cwwmag@aol.com. pMMni«« m m' |