Creative Woodworks & crafts 2001-03, страница 24

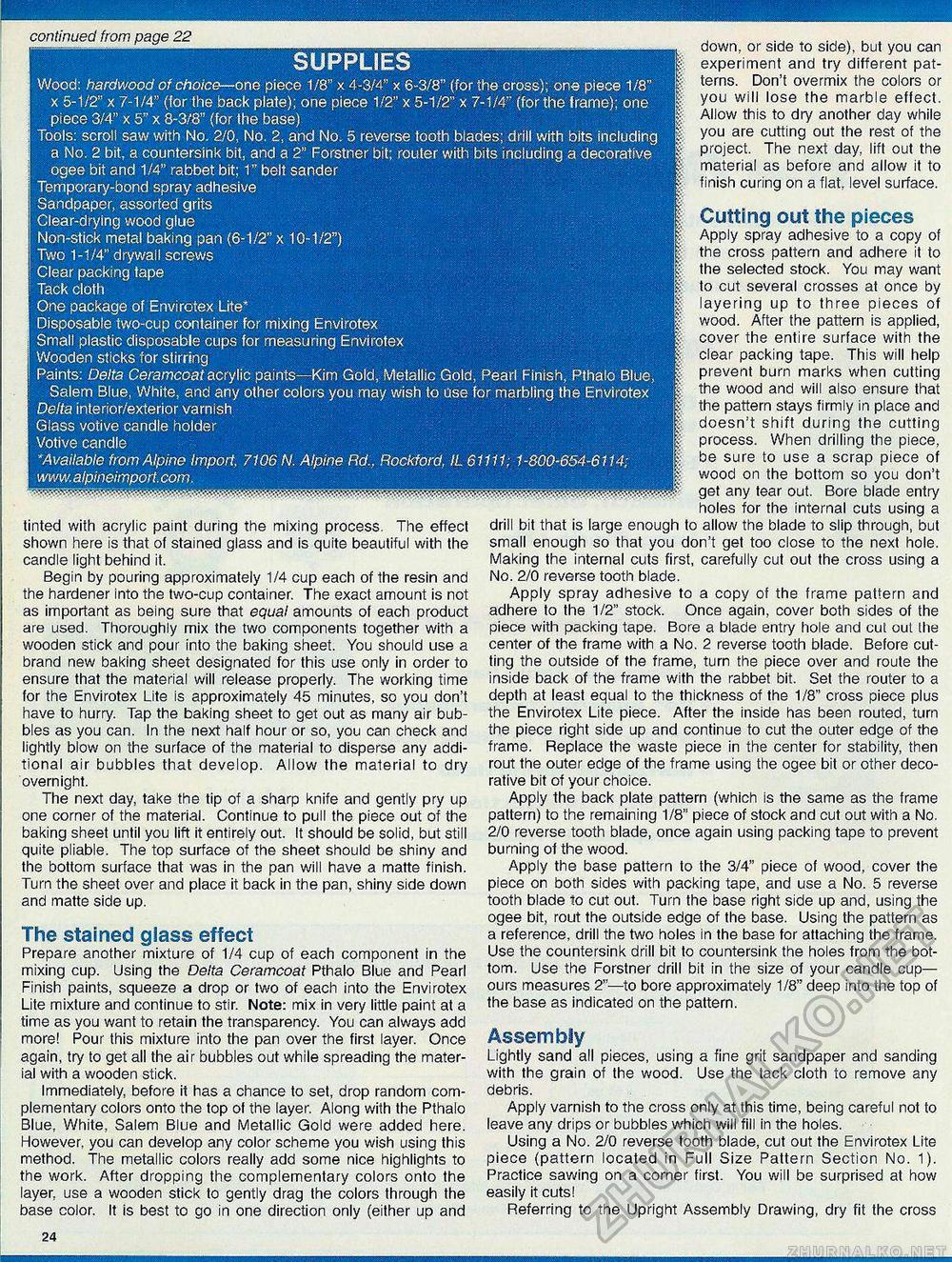

continued from page 22 SUPPLIES Wood: hardwood of choice—one piece 1/8" x 4-3/4" x 6-3/8" (for the cross); one piece 1/8" x 5-1/2" x 7-1/4" (for the back plate); one piece 1/2" x 5-1/2" x 7-1/4" (for the frame); one. piece 3/4" x 5" x 8-3/8" (for the base) Tools: scroll saw with No. 2/0, No. 2, and No. 5 reverse tooth blades; drill with bits including a No. 2 bit, a countersink bit, and a 2" Forstner bit; router with bits including a decorative ogee bit and 1/4" rabbet bit; 1" belt sander Temporary-bond spray adhesive Sandpaper, assorted grits Clear-drying wood glue Non-stick metal baking pan (6-1/2" x 10-1/2") Two 1-1/4" drywall screws Clear packing tape Tack cloth One package of Envirotex Lite* Disposable two-cup container for mixing Envirotex Small plastic disposable cups for measuring Envirotex Wooden sticks for stirring Paints: Delta Ceramcoat acrylic paints—Kim Gold, Metallic Gold, Pearl Finish, Pthalo Blue, Salem Blue, White, and any other colors you may wish to Ctse for marbling the Envirotex Delta interior/exterior varnish Glass votive candle holder Votive candle *Available from Alpine Import, 7106 N. Alpine Rd., Rockford, IL 61111; 1-800-654-6114; www.alpineimport. com. tinted with acrylic paint during the mixing process. The effect shown here is that of stained glass and is quite beautiful with the candle light behind it. Begin by pouring approximately 1/4 cup each of the resin and the hardener into the two-cup container. The exact amount is not as important as being sure that equal amounts of each product are used. Thoroughly mix the two components together with a wooden stick and pour into the baking sheet. You should use a brand new baking sheet designated for this use only in order to ensure that the material will release properly. The working time for the Envirotex Lite is approximately 45 minutes, so you don't have to hurry. Tap the baking sheet to get out as many air bubbles as you can. In the next half hour or so, you can check and lightly blow on the surface of the material to disperse any additional air bubbles that develop. Allow the material to dry overnight. The next day, take the tip of a sharp knife and gently pry up one corner of the material. Continue to pull the piece out of the baking sheet until you lift it entirely out. It should be solid, but still quite pliable. The top surface of the sheet should be shiny and the bottom surface that was in the pan will have a matte finish. Turn the sheet over and place it back in the pan, shiny side down and matte side up. The stained giass effect Prepare another mixture of 1/4 cup of each component in the mixing cup. Using the Delta Ceramcoat Pthalo Blue and Pearl Finish paints, squeeze a drop or two of each into the Envirotex Lite mixture and continue to stir. Note: mix in very little paint at a time as you want to retain the transparency. You can always add more! Pour this mixture into the pan over the first layer. Once again, try to get all the air bubbles out while spreading the material with a wooden stick. Immediately, before it has a chance to set, drop random complementary colors onto the top of the layer. Along with the Pthalo Blue, White, Salem Blue and Metallic Gold were added here. However, you can develop any color scheme you wish using this method. The metallic colors really add some nice highlights to the work. After dropping the complementary colors onto the layer, use a wooden stick to gently drag the colors through the base color. It is best to go in one direction only (either up and , down, or side to side), but you can | experiment and try different pat- | terns. Don't overmix the colors or & you will lose the marble effect. | Allow this to dry another day while | you are cutting out the rest of the ■<: project. The next day, lift out the | material as before and allow it to | finish curing on a flat, level surface. I I Cutting out the pieces | Apply spray adhesive to a copy of | the cross pattern and adhere it to | the selected stock. You may want | to cut several crosses at once by j layering up to three pieces of | wood. After the pattern is applied, | cover the entire surface with the | clear packing tape. This will help | prevent burn marks when cutting | the wood and will also ensure that i the pattern stays firmly in place and | doesn't shift during the cutting | process. When drilling the piece, | be sure to use a scrap piece of | wood on the bottom so you don't get any tear out. Bore blade entry holes for the internal cuts using a drill bit that is large enough to allow the blade to slip through, but small enough so that you don't get too close to the next hole. Making the internal cuts first, carefully cut out the cross using a No. 2/0 reverse tooth blade. Apply spray adhesive to a copy of the frame pattern and adhere to the 1/2" stock. Once again, cover both sides of the piece with packing tape. Bore a blade entry hole and cut out the center of the frame with a No. 2 reverse tooth blade. Before cutting the outside of the frame, turn the piece over and route the inside back of the frame with the rabbet bit. Set the router to a depth at least equal to the thickness of the 1/8" cross piece plus the Envirotex Lite piece. After the inside has been routed, turn the piece right side up and continue to cut the outer edge of the frame. Replace the waste piece in the center for stability, then rout the outer edge of the frame using the ogee bit or other decorative bit of your choice. Apply the back plate pattern (which is the same as the frame pattern) to the remaining 1/8" piece of stock and cut out with a No. 2/0 reverse tooth blade, once again using packing tape to prevent burning of the wood. Apply the base pattern to the 3/4" piece of wood, cover the piece on both sides with packing tape, and use a No. 5 reverse tooth blade 1o cut out. Turn the base right side up and, using the ogee bit, rout the outside edge of the base. Using the pattern as a reference, drill the two holes in the base for attaching the frame. Use the countersink drill bit to countersink the holes from the bottom. Use the Forstner drill bit in the size of your candle cup— ours measures 2"—to bore approximately 1/8" deep into the top of the base as indicated on the pattern. Assembly Lightly sand all pieces, using a fine grit sandpaper and sanding with the grain of the wood. Use the tack cloth to remove any debris. Apply varnish to the cross only at this time, being careful not to leave any drips or bubbles which will fill in the holes. Using a No. 2/0 reverse tooth blade, cut out the Envirotex Lite piece (pattern located in Full Size Pattern Section No. 1). Practice sawing on a corner first. You will be surprised at how easily it cuts! Referring to the Upright Assembly Drawing, dry fit the cross 24 |