Creative Woodworks & crafts 2002-08, страница 35

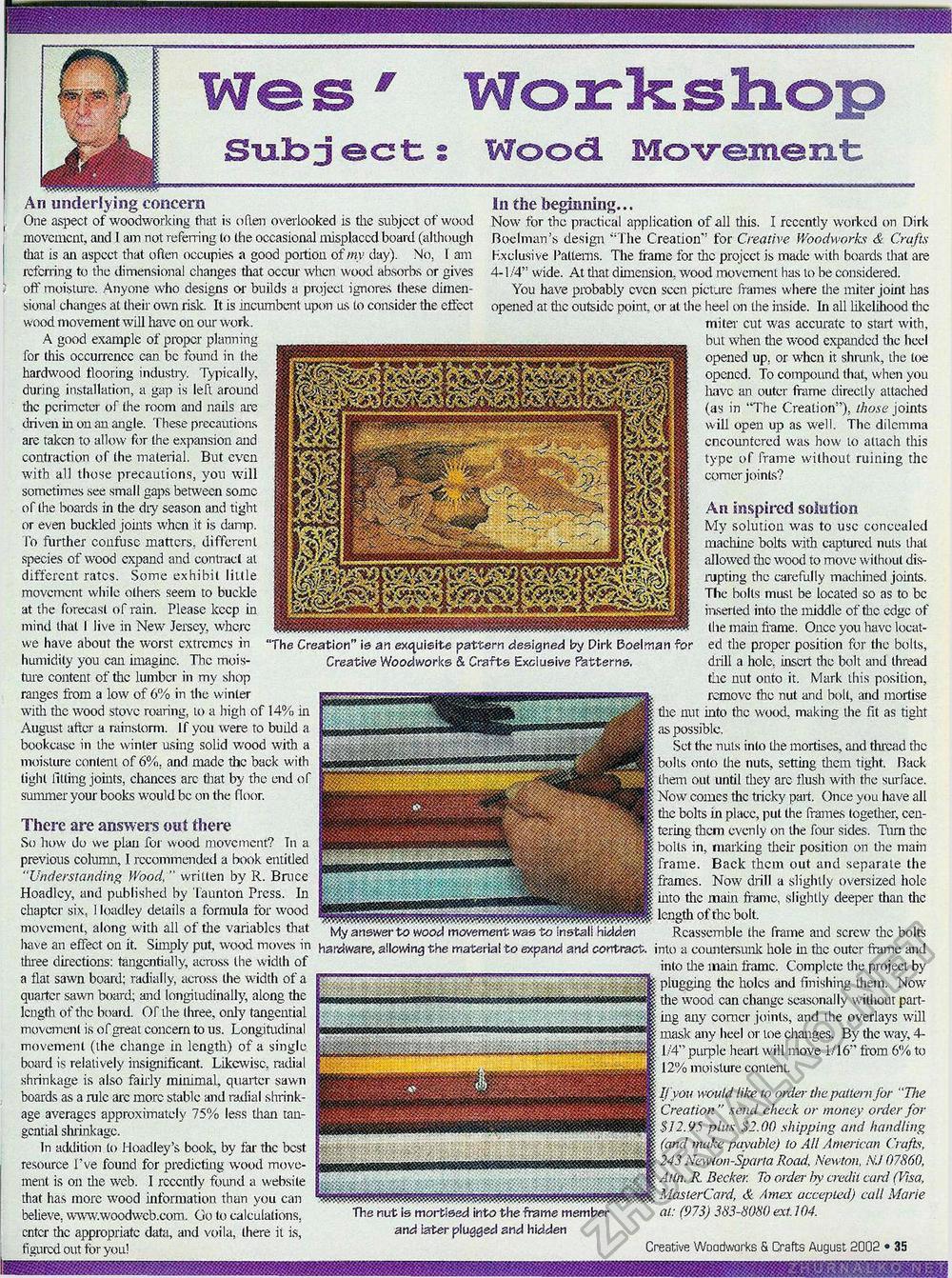

An underlying concern One aspect of woodworking that is often overlooked is the subject of wood movement, and I am not referring to the occasional misplaccd board (although that is an aspect that often occupies a good portion of my day). No. 1 am referring to the dimensional changes that occur when wood absorbs or gives off moisture. Anyone who designs or builds a project ignores these dimensional changes at their own risk. It is incumbent upon us to consider the effect wood movement will have on our work. A good example of proper planning for this occurrence can be found in the hardwood flooring industry. Typically, during installation, a gap is left around the perimeter of (he room and nails are driven in on an angle. These precautions are taken to allow tor the expansion and contraction of the material. But even with all those precautions, you will sometimes see small gaps between some of (he boards in the dry season and tight or even buckled joints when it is damp. To further confuse matters, different species of wood expand and contract at different rates. Some exhibit little movement while others seem to buckle at the forecast of rain. Please keep in mind that I live in New Jersey, where we have about the worst extremes in humidity you can imagine. The moisture content of the lumber in my shop ranges from a low of 6% in the winter with the wood stove roaring, Lo a high of 14% in August after a rainstorm. If you were to build a bookcase in the winter using solid wood with a moisture content of 6%. and made the back with tight fitting joints, chanccs arc that by the end of summer your books would be on the floor. There are answers out there So how do we plan for wood movement? In a previous column, I recommended a book entitled "Understanding Wood, " written by R. Bmce Hoadlcy, and published by Taunton Press. In chapter six, 1 loadley details a formula for wood movement, along with all of the variables that 'The Creation" is an exquisite pattern designed by Dirk Boelman for Creative Woodworks & Crafts Exclusive Patterns. have an effect on it. three directions: tangentially, across the width of a flat sawn board; radially, across the width of a quarter sawn board; and longitudinally, along the length of the board. Of the three, only tangential movement is ofgreat concern to us. Longitudinal movement (the change in length) of a single board is relatively insignificant. Likewise, radial shrinkage is also fairly minimal, quarter sawn boards as a rule arc more stable and radial shrinkage averages approximately 75% less than tangential shrinkage. In addition to Hoadley's book, by far the best resource I've found for predicting wood movement is on the web. I recently found a website that has more wood information than you can believe, www.woodwcb.com. Go to calculations, enter the appropriate data, and voila, there it is, figured out tor you! My answer to wood movement was to install hidden in the beginning... Now tor the practical application of all this. I recently worked on Dirk Rodman's design "The Creation" for Creative Woodworks & Crafts Kxelusive Patterns. The frame for the project is made with boards that are 4-1 /4" wide. At that dimension, wood movement has to be considered. You have probably even seen picture frames where the miter joint lias opened at the outside point, or at the heel on the inside. In all likelihood the miter cut was accurate to start with, but when the wood expanded the heel opened up, or when it shrunk, the toe opened. To compound that, when you have an outer frame directly attached (as in "The Creation"), those joints will open up as well. The dilemma encountered was how lo attach this type of frame without ruining the corner joints? An inspired solution My solution was to use concealed machine bolts with captured nuts that allowed the wood to move without disrupting the carefully machined joints. Tlie bolts must be located so as to be inserted into the middle of the edge of tlie main frame. Oncc you have located the proper position for the bolls, drill a hole, insert the bolt and thread tlie nut onto it. Mark this position, remove the nut and bolt, and mortise | tlie nut into the wood, making the fit as tight as possible. Set the nuts into tlie mortises, and thread the bolts onto the nuts, setting them tight. Back them out until they are flush with the surface. Now comes the tricky part. Once you have all \ the bolts in place, put the frames together, centering them evenly on the four sides. Turn the bolts in, marking their position on the main frame. Back them out and separate the ; frames. Now drill a slightly oversized hole into the main frame, slightly deeper than the i length of the bolt. Reassemble the frame and screw the bolts Simply put, wood moves in hardware, allowing the material to expand and contract, into a countersunk hole in the outer frame and into tlie main frame. Complete the project by plugging the holes and finishing them. Now the wood can change seasonally without part-any corner joints, and the overlays will mask any heel or toe changes. By the way, 4-1/4" purple heart will move 1/16" from 6% to 12% moisture content. If you would like to order the pattern for "The Creation " send check or money order for $ J 2.95 plus $2.00 shipping and handling malic payable) to All American Crafts, 243 Newton-Sparta Road, Newton. N.J 07860, Attn. R. Becker. To order hv credit card (Visa, MasterCard, & Amex accepted) call Marie The nut is mortised into the frame member at: (973) 383-8080 ext. 104. and later plugged and hidden 18 • Creative Woodworks S. Crafts August 2002 Subjects WoodL Movement: |