Creative Woodworks & crafts 2003-09, страница 36

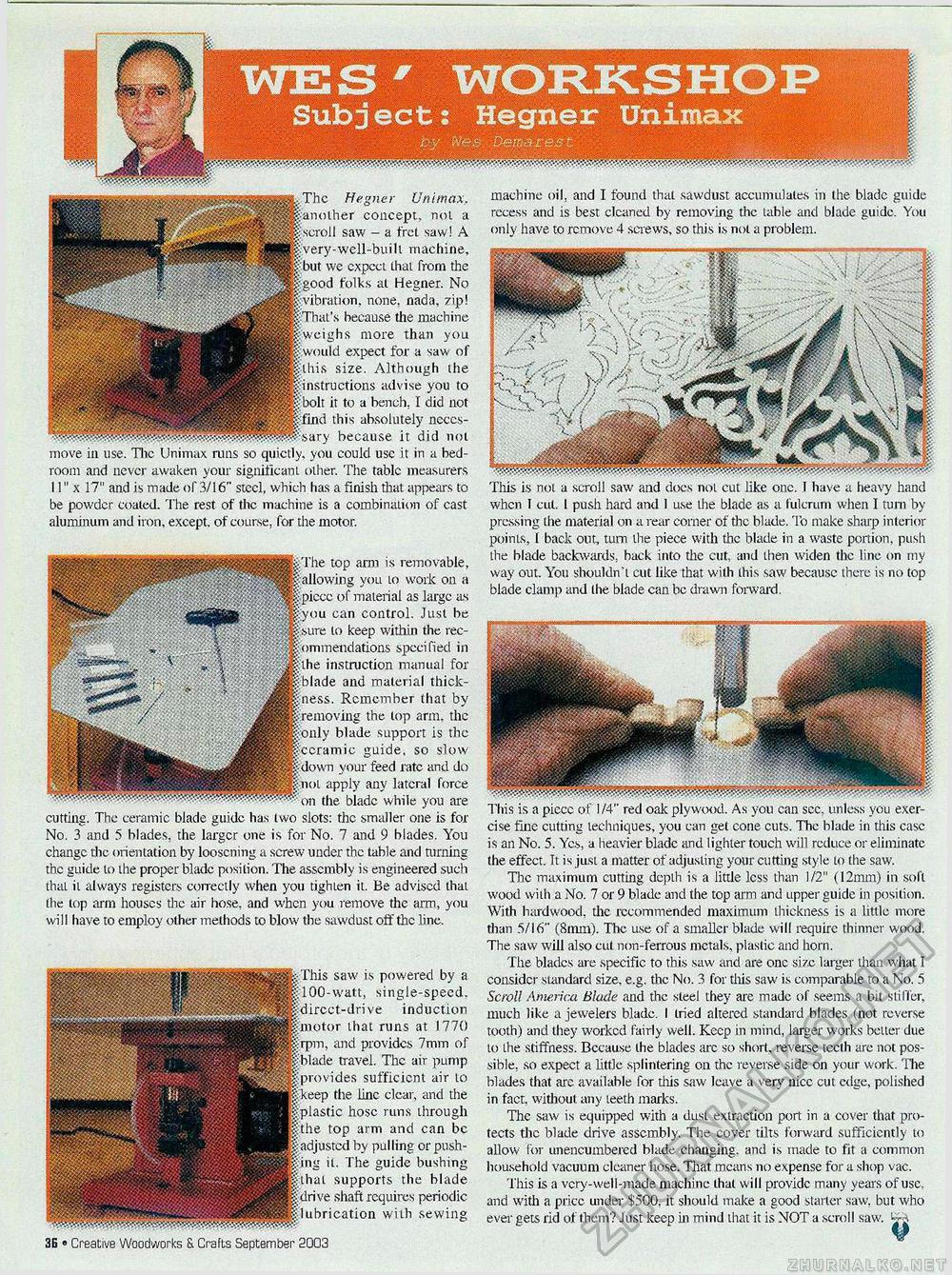

36 • Creative Woodworks & Crafts September 2003 the bottom supports. shelf supports. This is a piccc of 1/4" red oak plywood. As you can see. unless you exercise fine cutting techniques, you can get cone cuts. The blade in this ease is an No. 5. Yes, a heavier blade and lighter touch will reduce or eliminate the effect. It is just a matter of adjusting your cutting style to the saw. The maximum cutting depth is a little less than 1/2" (12mm) in soft wood with a No. 7 or 9 blade and the top arm and upper guide in position. With hardwood, die recommended maximum thickness is a little more than 5/16" (8mm). The use of a smaller blade will require thinner wood. The saw will also cut non-ferrous metals, plastic and horn. The blades are specific to this saw and are one size larger than what I consider standard size, e.g. the No. 3 for this saw is comparable to a No. 5 Scroll America Blade and the steel they are made of seems a bit stiffen much like a jewelers blade. I Iried altered standard blades (not reverse tooth) and they worked fairly well. Keep in mind, larger works better due to the stiffness. Because the blades arc so short, reverse teeth are not possible. so expect a little splintering on the reverse side on your work. The blades that arc available for this saw leave a very nice cut edge, polished in fact, without any teeth marks. The saw is equipped with a dust extraction port in a cover that protects the blade drive assembly. The cover tilts forward sufficiently to allow for unencumbered blade changing, and is made to fit a common household vacuum cleaner hose. That means no expense for a shop vac. This is a very-well-made machine that will provide many years of use, and with a price under $500, it. should make a good starter saw, but who ever gets rid of them? Just keep in mind that it is NOT a scroll saw. u-j* ,Thc Hegner Unimax. concept, not a iscroll saw - a fret saw! A Jvery-well-bui 11 mac hi ne, we expect that from the :-good folks at Hegner. No vibration, none, nada, zip! because the machine >:weighs more than you expect for a saw of •this size. Although the ^instructions advise you to {bolt it to a bench. I did not this absolutely neccs-because it did not move in use. The Unimax runs so quietly, you could use it in a bedroom and never awaken your significant other. The tabic measurers 11" x 17" and is made of 3/16" steel, which has a finish that appears to be powder coated. The rest of the machine is a combination of cast aluminum and iron, except, of course, for the motor. ji-.The top arm is removable, p allowing you to work on a pipiccc of material as large as iiyou can control. Just be i sure to keep within the rec-•jommendations specified in I'lhe instruction manual for sblade and material thick-Sness. Remember that by ^removing the top arm, the Ifonly blade support is the I'ceramic guide, so slow Jdown your feed rate and do Knot apply any lateral force on the blade while you are cutting. The ceramic blade guide has two slots: the smaller one is for No. 3 and 5 blades, the larger one is for No. 7 and 9 blades. You change the orientation by loosening a screw under the table and turning the guide to the proper blade position. The assembly is engineered such that it always registers correctly when you tighten it. Be advised that the top arm houses the air hose, and when you remove the arm, you will have to employ other methods to blow the sawdust off the line. saw is powered by a watt, single-speed. induction that runs at 1770 and provides 7mm of travel. The air pump des sufficient air to the line dear, and the hose runs through top arm and can be by pulling orpush-. The guide bushing supports the blade requires periodic ubrication with sewing machine oil. and I found that sawdust accumulates in the blade guide recess and is best clcaned by removing the table and blade guide. You only have to remove 4 screws, so this is not a problem. ______________________saw and does not cut like one. I have a heavy hand when I cut. I push hard and 1 use the blade as a fulcrum when I turn by-pressing the material on a rear corner of the blade. To make sharp interior points, I back out, turn tine piece with the blade in a waste portion, push the blade backwards, hack into the cut, and then widen the line on my way out. You shouldn't cut like that with this saw because there is no top blade clamp and the blade can be drawn forward. |