Creative Woodworks & crafts 2003-09, страница 44

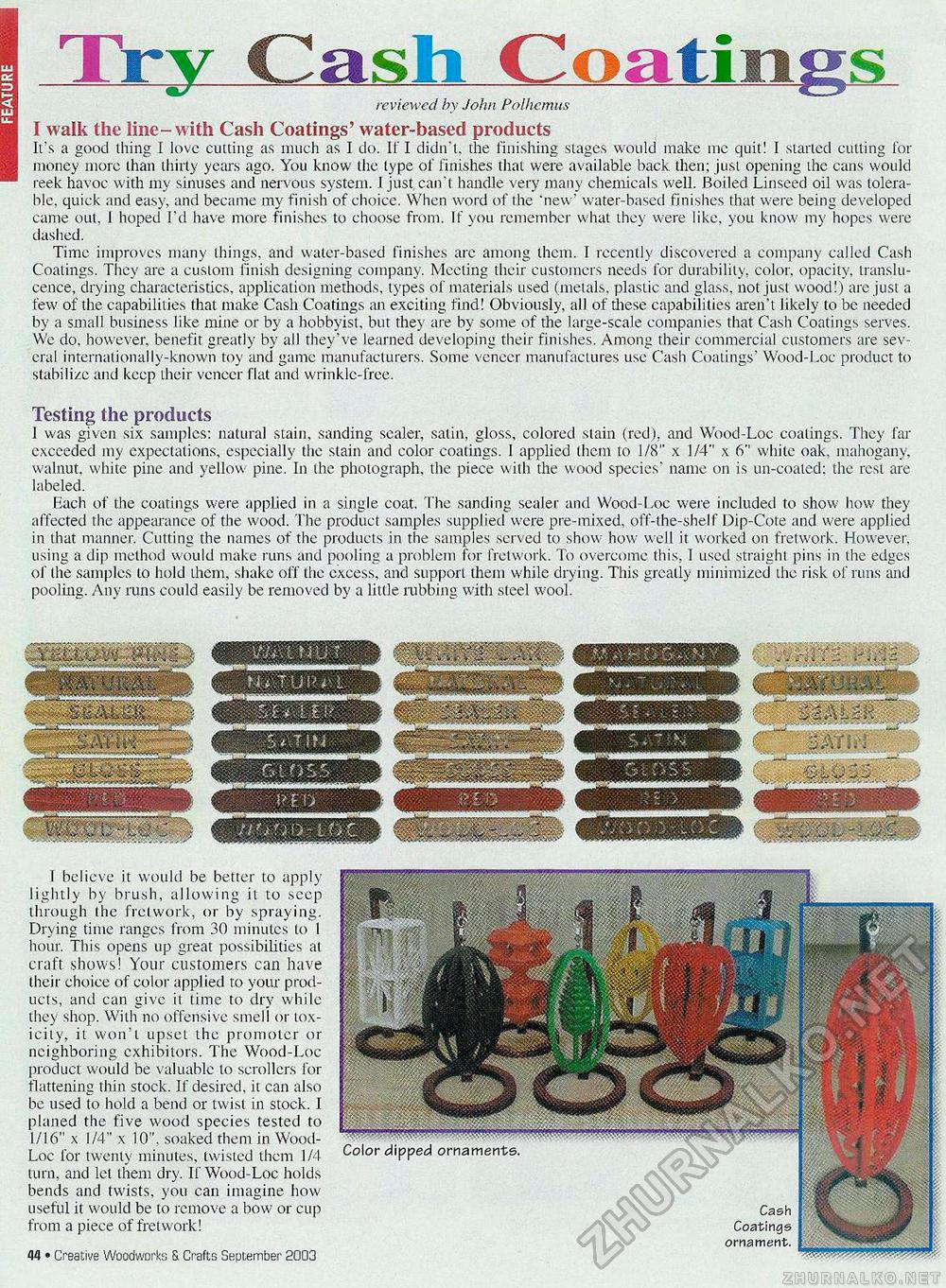

Try Cash Coatings reviewed by John Polhemus I walk the line-with Cash Coatings' water-based products Irs a good thing I love cutting as much as I do. 11' I didn't, the finishing stages would make me quit! I started cutting for money more than thirty years ago. You know the type of finishes that were available back then; just opening the cans would reek havoc with my sinuses and nervous system. I just, can't handle very many chemicals well. Boiled Linseed oil was tolerable. quick and easy, and became my finish of choice. When word of the "new' water-based finishes that were being developed came out, 1 hoped I'd have more finishes to choose from. If you remember what they were like, you know my hopes were dashed. Time improves many things, and water-based finishes are among them. I recently discovered a company called Cash Coatings. They are a custom finish designing company. Meeting their customers needs for durability, color, opacity, translu-cence, drying characteristics, application methods, types of materials used (metals, plastic and glass, not just wood!) are just a few of the capabilities that make Cash Coatings ait exciting find! Obviously, all of these capabilities aren't likely to be needed by a small business like mine or by a hobbyist, but they are by some of the large-scale companies that Cash Coatings serves. We do. however, benefit greatly by all they've learned developing their finishes. Among their commercial customers are several internationally-known toy and game manufacturers. Some veneer manufactures use Cash Coatings' Wood-Loc product to stabilize and keep their veneer flat and wrinkle-free. Testing the products 1 was given six samples: natural stain, sanding sealer, satin, gloss, colored stain (red), and Wood-Loc coalings. They far exceeded my expectations, especially the stain and color coatings. I applied them to 1/8" x 1/4" x 6" white oak. mahogany, walnut, white pine and yellow pine. In the photograph, the piece with the wood species' name on is un-coated; ihe rest are labeled. Each of the coatings were applied in a single coat. The sanding sealer and Wood-Loc were included to show how they affected the appearance of the wood. T he product samples supplied were pre-mixed, off-the-shelf Dip-Cote and were applied in that manner. Cutting the names of the products in the samples served to show how well it worked on fretwork. However, using a dip method would make runs and pooling a problem for fretwork. To overcome this. I used straight pins in the edges of Ihe samples to hold them, shake off the excess, and support them while drying. This greatly minimized the risk of runs and pooling. Any runs could easily be removed by a little rubbing with steel wool. I believe it would be better to apply lightly by brush, allowing it to seep through the fretwork, or by spraying. Drying time ranges from 30 minutes to 1 hour. This opens up great possibilities at craft shows! Your customers can have their choice of color applied to your products, and can give it time to dry while they shop. With no offensive smell or toxicity, it won't upset the promoter or neighboring exhibitors. The Wood-Loc product would be valuable to scrollers for flattening thin stock. If desired, it can also be used to hold a betid or twist in stock. 1 planed the five wood species tested to 1/16" x 1/4" x 10". soaked them in Wood-Loc for twenty minutes, twisted them 1/4 turn, and let them dry. If Wood-Loc holds bends and twists, you can imagine how useful it would be to remove a bow or cup from a piece of fretwork! 44 • Creative Woodworks & Crafts September 2003 the bottom supports. shelf supports. |