Creative Woodworks & crafts 2003-11, страница 39

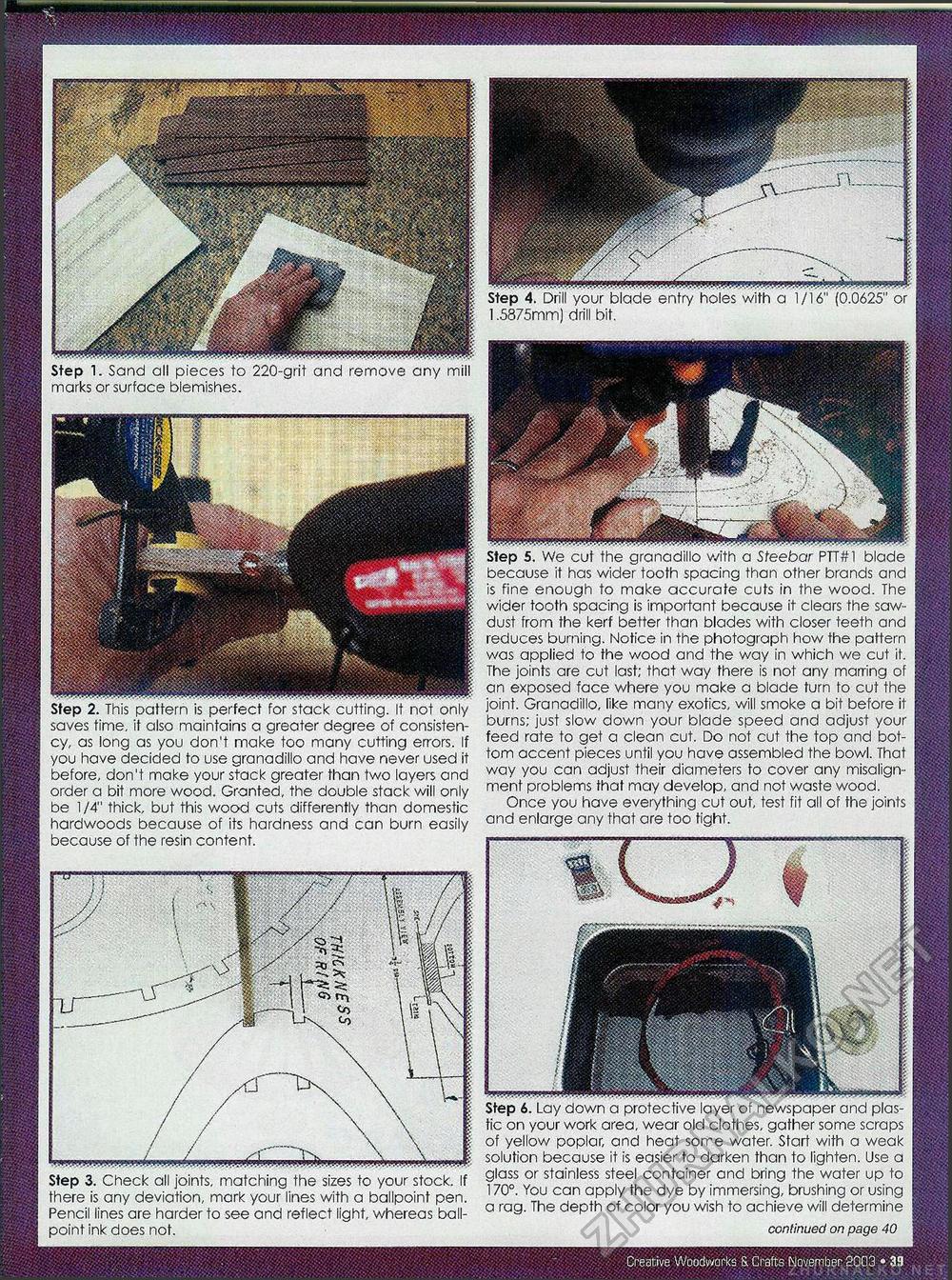

Step 4. Drill your blade entry holes with a 1/16" (0.0625" or 1,5875mm) drill bit. Step 1. Sand all pieces to 220-grit and remove any mill marks or surface blemishes. Step 5. We cut the granadillo with a Steebar PTT#1 blade because it has wider tooth spacing than other brands and is fine enough to make accurate cuts in the wood. The wider tooth spacing is important because it clears the sawdust from the kerf better than blades with closer teeth and reduces burning. Notice in the photograph how the pattern was applied to the wood and the way in which we cut it. The joints are cut last; that way there is not any marring of an exposed face where you make a blade turn to cut the joint. Granadillo, like many exotics, will smoke a bit before it burns; just slow down your blade speed and adjust your feed rate to get a clean cut. Do not cut the top and bottom accent pieces until you have assembled the bowl. That way you can adjust their diameters to cover any misalignment problems that may develop, and not waste wood. Once you have everything cut out, test fit all of the joints and enlarge any that are too tight. Step 2. This pattern is perfect for stack cutting. It not only saves time, it also maintains a greater degree of consistency, as long as you don't make too many cutting errors. If you have decided to use granadillo and have never used it before, don't make your stack greater than two layers and order a bit more wood. Granted, the double stack will only be 1/4" thick, but this wood cuts differently than domestic hardwoods because of its hardness and can burn easily because of the resin content. Step 6. Lay down a protective layer of newspaper and plastic on your work area, wear old clothes, gather some scraps of yellow poplar, and heat sorre water. Start with a weak solution because it is easier to darken than to lighten. Use a glass or stainless steel container and bring the water up to 170°. You can apply the dye by immersing, brushing or using a rag. The depth of color you wish to achieve will determine continued on page 40 Step 3. Check all joints, matching the sizes to your stock. If there is any deviation, mark your lines with a ballpoint pen. Pencil lines are harder to see and reflect light, whereas ballpoint ink does not. |