Creative Woodworks & crafts 2004-03, страница 45

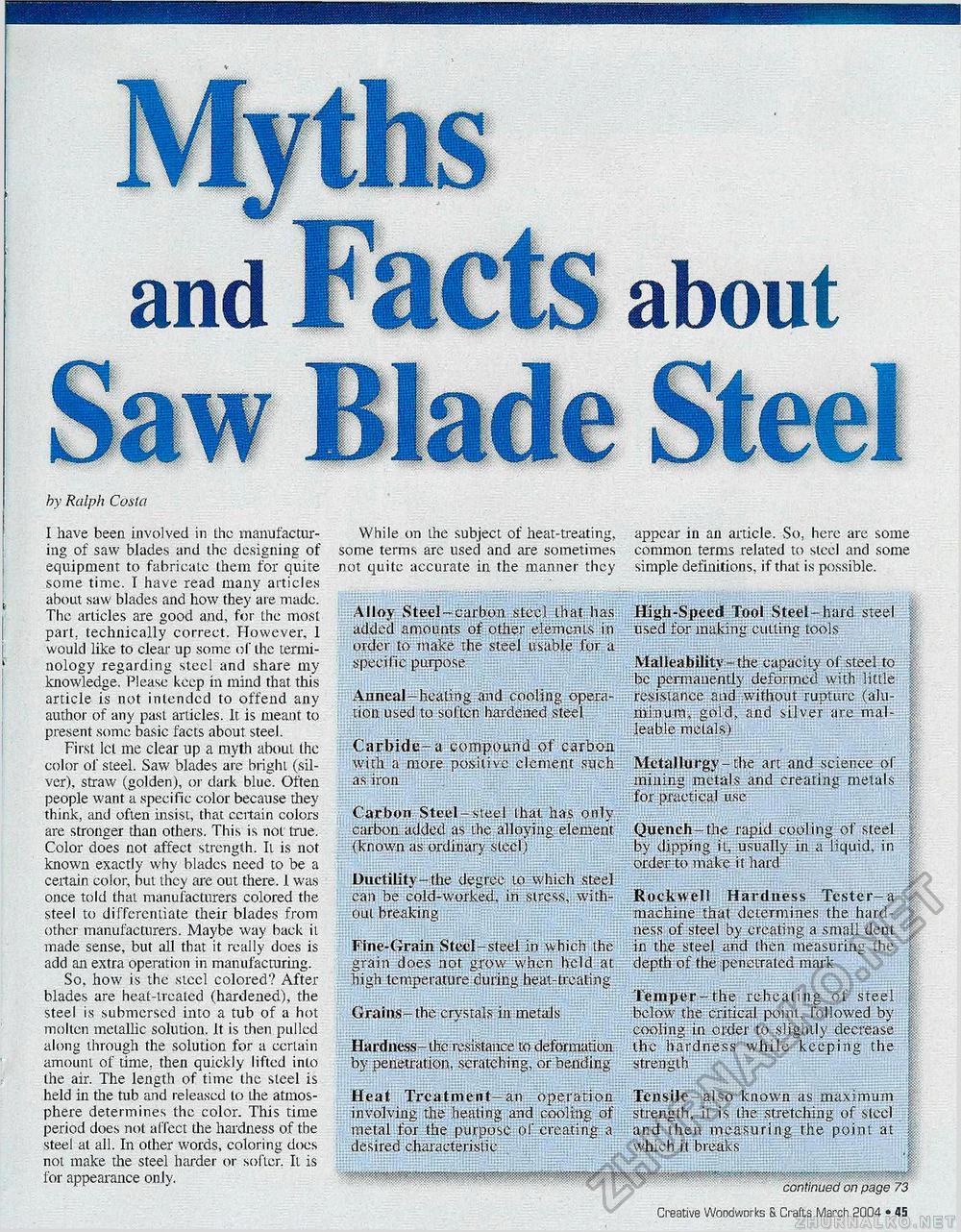

by Ralph Costa I have been involved in the manufacturing of saw blades and the designing of equipment to fabricate them for quite some time. I have read many articles about saw blades and how they are made. The articles are good and, for ihc most part, technically correct. However, 1 would like to clear up some of the terminology regarding steel and share my knowledge. Please keep in mind that this article is not intended to offend any author of any past articles. It is meant to present some basic facts about steel. First let me clear up a myth about the color of steel. Saw blades are bright (silver), straw (golden), or dark blue. Often people want a specific color because they think, and often insist, that ccitain colors are stronger than others. This is not true. Color does not affect strength. It is not known exactly why blades need to be a certain color, but they are out there. 1 was once told that manufacturers colored the steel to differentiate their blades from other manufacturers. Maybe way back il made sense, but all that it really does is add an extra operation in manufacturing. So, how is the steel colored? After blades are heat-treated (hardened), the steel is submersed into a tub of a hot molten metallic solution. It is then pulled along through the solution for a ccrtain amount of time, then quickly lifted into the air. The length of time the steel is held in the tub and released to the atmosphere determines the color. This time period does not affect the hardness of the steel at all. In other words, coloring docs not make the steel harder or softer. It is for appearance only. While on the subject of heat-treating, some terms are used and are sometimes not quite accurate in the manner they Alloy Steel-carbon steel Ihaf has added amounts of other elements in order to make the steel usable for a specific purpose Anneal-healing and cooling operation used to soften hardened steei Carbide-a compound of carbon with a more positive clement such as iron Carbon Steel- steel lhat has only carbon added as the alloying element (known as ordinary slecl} Ductility-the degree to which steel can be cold-worked., in stress, without breaking Fine-Grain Steel-steel in which the grain does not grow when held at high temperature during heat-treating Girains-the crystals in metals Hardness-(he resistance to deformation by penetration, scratching, or bending Heat Treatment-an operation involving the heating and cooling of metal for the purpose of creating a desired characteristic appear in an article. So, here are some common terms related to steel and some simple definitions, if that is possible. High-Speed Tool Steel-hard steel f used for making cutting tools Malleability-the capacity of steel to ; he permanently deformed with little §| resistance and without rupture (alu- fi minum, gold, and silver are mal- | leable metals) iiigpyppS; ' !• Metallurgy-the art and science of & mining metals and creating metals f for practical use Quench-the rapid cooling of steel | by dipping it, usually in a liquid, in | order to make it hard Rockwell Hardness Tester-a | machine that determines the hard- | ness of steel by creating a small dent |: in the steel and then measuring the E depth of the penetrated mark Temper-the reheating of steel | below the critical point, followed by I cooling in older to slightly decrease | the hardness while keeping the | strength p.- Tensile—also known as maximum |i strength, it is the stretching of steel § and then measuring the point at | which it breaks continued on page 73 about 14 • Creative Woodworks S. Crafts March 2004 |