Creative Woodworks & crafts 2004-03, страница 46

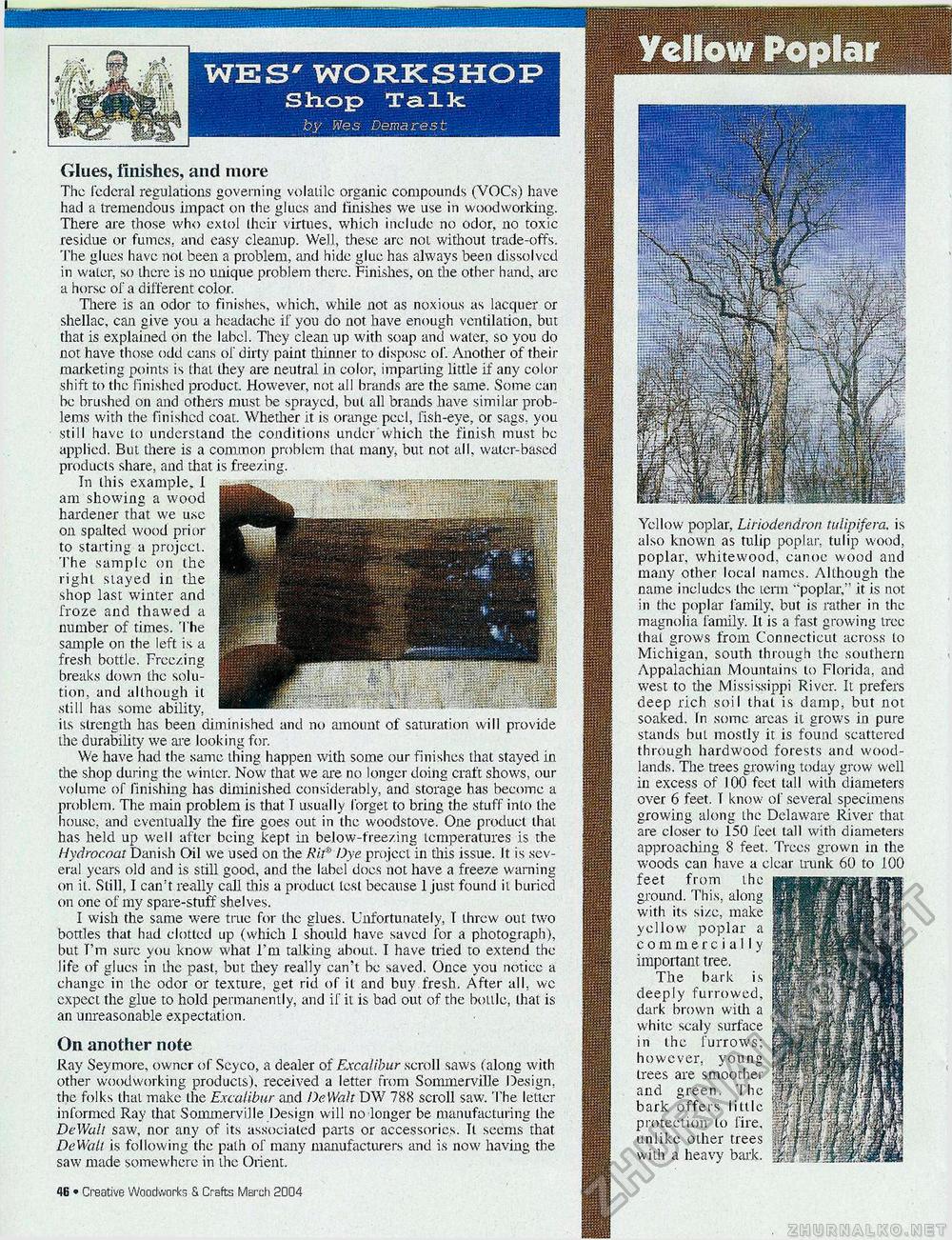

Yellow poplar, Liriodendron tulipifera. is also known as tulip poplar, tulip wood, poplar, whitewood. canoe wood and many other local names. Although the name includes the term "'poplar," it is not in the poplar family, but is rather in the magnolia family. It is a fast growing tree thai grows from Connecticut across to Michigan, south through the southern Appalachian Mountains to Florida, and west to the Mississippi River. It prefers deep rich soil thai is damp, but not soaked. In some areas it grows in pure stands but mostly it is found scattered through hardwood forests and woodlands. The trees growing today grow well in excess of 100 feet tall with diameters over 6 feet. T know of several specimens growing along the Delaware River that are closer to 150 feel tall with diameters approaching 8 feet. Trees grown in the woods can have a clear trunk 60 to 100 Glues, finishes, and more The federal regulations governing volatile organic compounds (VOCs) have had a tremendous impact on the glues and finishes we use in woodworking. There are those who extol (heir virtues, which include no odor, no toxic residue or fumes, and easy cleanup. Well, these arc not without trade-offs. The glues have not been a problem, and hide glue has always been dissolved in waler, so there is no unique problem there. Finishes, on the other hand, arc a horse of a different color. There is an odor to finishes, which, while not as noxious as lacquer or shellac, can give you a headache if you do not have enough ventilation, but that is explained on the label. They clean up with soap and water, so you do not have those odd cans of dirty paint thinner to dispose of. Another of their marketing points is that Ihey are neutral in color, imparting little if any color shift to the finished product. However, not all brands are the same. Some can be brushed on and others must be sprayed, but all brands have similar problems with the finished coat. Whether it is orange peel, fish-eye, or sags, you still have to understand the conditions under which the finish must be applied. But there is a common problem thai many, but not all, water-based products share, and that is freezing. In this example, 1 am showing a wood hardener that, we u.sc on spalted wood prior to starting a projccl. The sample on the right stayed in the shop last winter and froze and thawed a number of times. The sample on the left is a fresh bottle. Frce/.ing breaks down the solution, and although it still has some ability, its strength has been diminished and no amount of saturation will provide the durability we are looking for. We have had the same ihing happen with some our finishes that stayed in the shop during the winter. Now that we are no longer doing craft shows, our volume of finishing has diminished considerably, and storage has become a problem. The main problem is that I usually forget to bring the stuff into the house, and eventually the fire goes out in the woodstove. One product thai has held up well after being kept in below-freezing temperatures is the Hydrocoat Danish Oil we used on the Rif Dye. project in this issue. It is several years old and is still good, and the label does not have a freeze warning on it. Still, I can't really call this a product test because 1 just found ii buried on one of my spare-stuff shelves. I wish the same were true for the glues. Unfortunately, I threw out two bottles that had clotted up (which I should have saved for a photograph), but I'm sure you know what I'm talking about. I have tiied to extend the life of glues in the past, but they really can't be saved. Once you notice a change in the odor or texture, get rid of it and buy fresh. After all, vvc cxpect the glue to hold permanently, and if it is bad out of the bottle, that is an unreasonable expectation. On another note Ray Seymore, owner of Scyco, a dealer of Excalibur scroll saws (along with other woodworking products), received a letter from Sommerville Design, the folks thai make the Excalibur and DeWah DW 788 scroll saw. The letter informed Ray that Sommerville Design will no longer be manufacturing the DeWah saw, nor any of its associated parts or accessories. It seems that DeWall is following the path of many manufacturers and is now having the saw made somewhere in the Orient. 14 • Creative Woodworks S. Crafts March 2004 |