Creative Woodworks & crafts 2004-09, страница 67

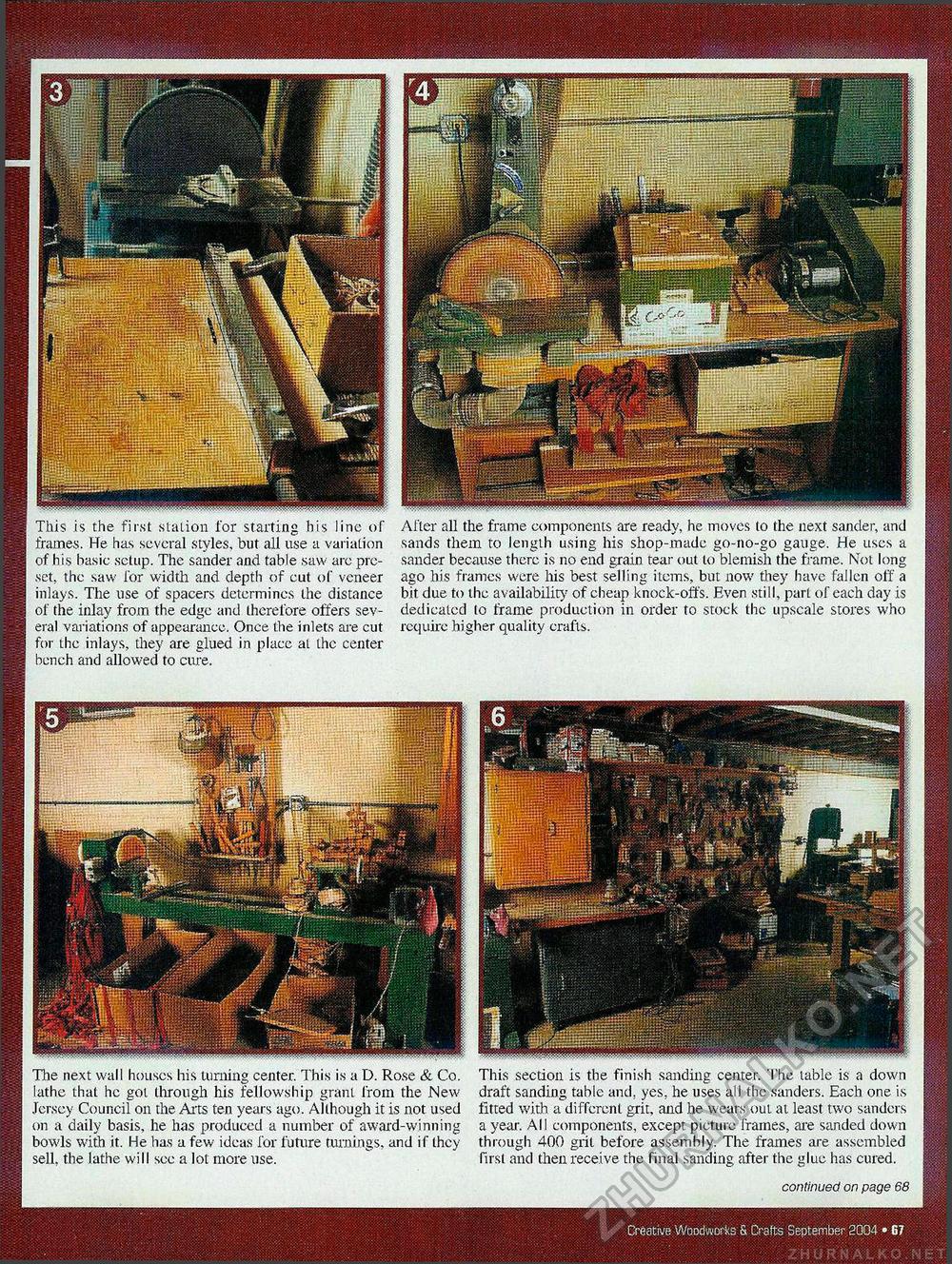

Creative Woodworks & Crafts September 2004 • 67 This is the first station for starting his line of frames. He has several styles, but all use a variation of his basic setup. The sander and table saw are preset, the saw for width and depth of cut of veneer inlays. The use of spacers determines the distance of the inlay from the edge and therefore offers several variations of appearance. Once the inlets are cut for Lhc inlays, they are glued in place at the center bench and allowed to cure. After all the frame components are ready, he moves lo the next sander, and sands them to length using his shop-made go-no-go gauge. He uses a sander because there is no end grain tear out lo blemish the frame. Not long ago his frames were his best selling items, but now they have fallen off a bit due to the availability of cheap knock-offs. F.ven still, part of each day is dedicated lo frame production in order to stock the upscale stores who require higher quality crafts. The next wall houses his turning center. This is a D. Rose & Co. lathe thai he gol through his fellowship grant from the New Jersey Council 011 the Arts ten years ago. Although it is not used on a daily basis, he has produced a number of award-winning bowls with it. He has a few ideas for future turnings, and if they sell, the lathe will see a lot more use. This section is the finish sanding center. The table is a down draft sanding table and. yes, he uses all the sanders. Each one is fitted with a different grit, and he wears out at least two sanders a year. All components, except picture frames, are sanded down through 400 grit before assembly. The frames are assembled first and then receive the final sanding after the glue has cured. continued on page 68 |