Creative Woodworks & crafts 2004-09, страница 66

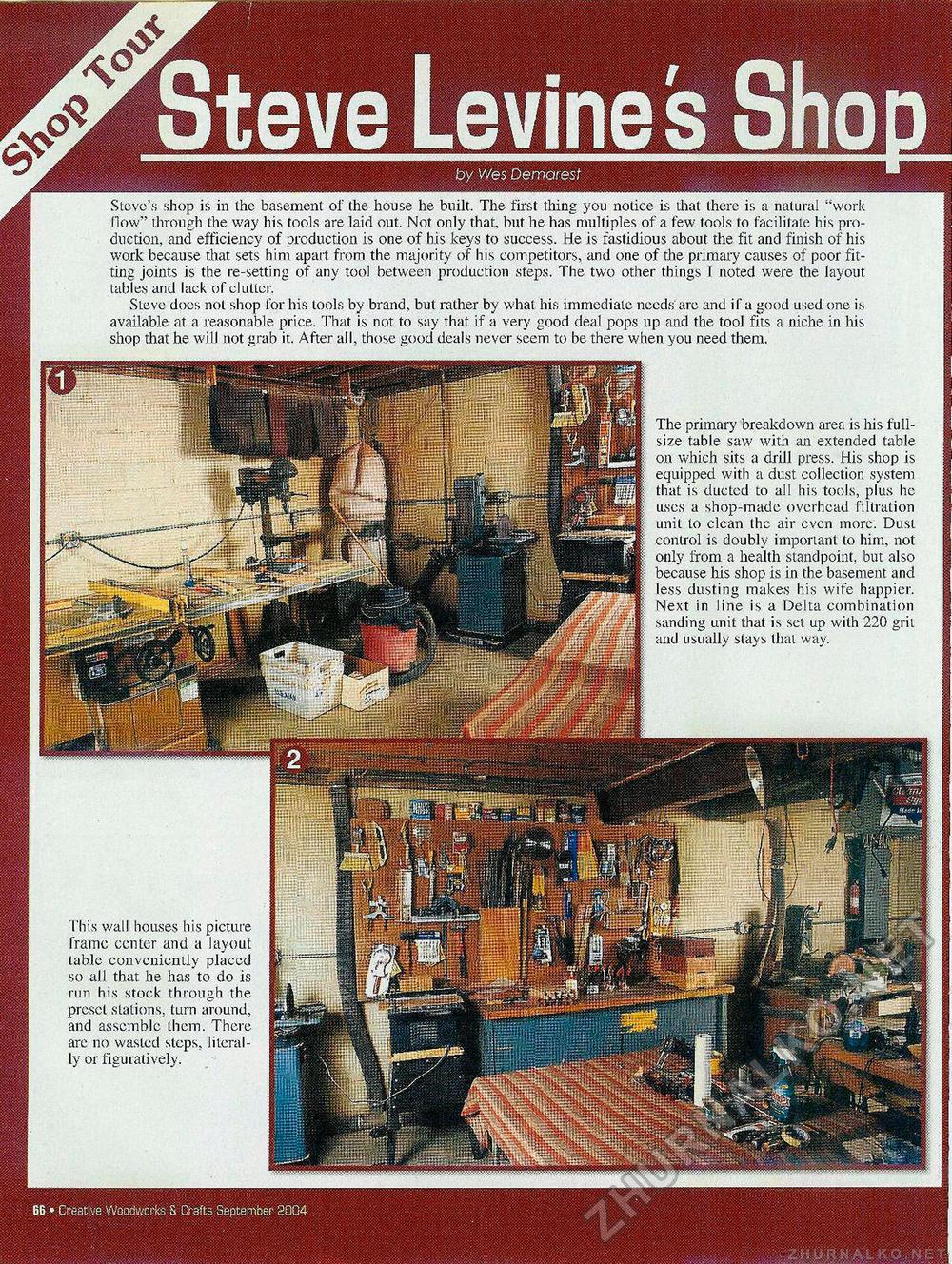

by Wes Demarest Steve's shop is in the basement of the house he built. The first thing you notice is that there is a natural "work How" through the way his tools are laid out. Not only that, but he has multiples of a few tools to facilitate his production, and efficiency of production is one of his keys to success. He is fastidious about the fit and finish of his work because that sets him apart from the majority of his competitors, and one of the primary causes of poor fitting joints is the re-setting of any tool between production steps. The two other things 1 noted were the layout tables and lack of clutter. Steve docs not shop for his tools by brand, but rather by what his immediate needs are and if a good used one is available at a reasonable price. That is not to say that if a very good deal pops up and the tool fits a niche in his shop that he will not grab it. After all, those good deals never seem to be there when you need them. The primary breakdown area is his full-size table saw with an extended table on which sits a drill press. His shop is equipped with a dust collection system that is ducted to all his tools, plus he uses a shop-made overhead filtration unit to clean the air even more. Dust control is doubly important to him, not only from a health standpoint, but also because his shop is in the basement and less dusting makes his wife happier. Next in line is a Delta combination sanding unit that is scl up with 220 grit and usually slays that way. This wall houses his picture frame ccntcr and a layout table conveniently placed so all that he has to do is run his stock through the preset stations, turn around, and assemble Ihem. There are no wasted steps, literally or figuratively. |