Creative Woodworks & crafts 2004-11, страница 32

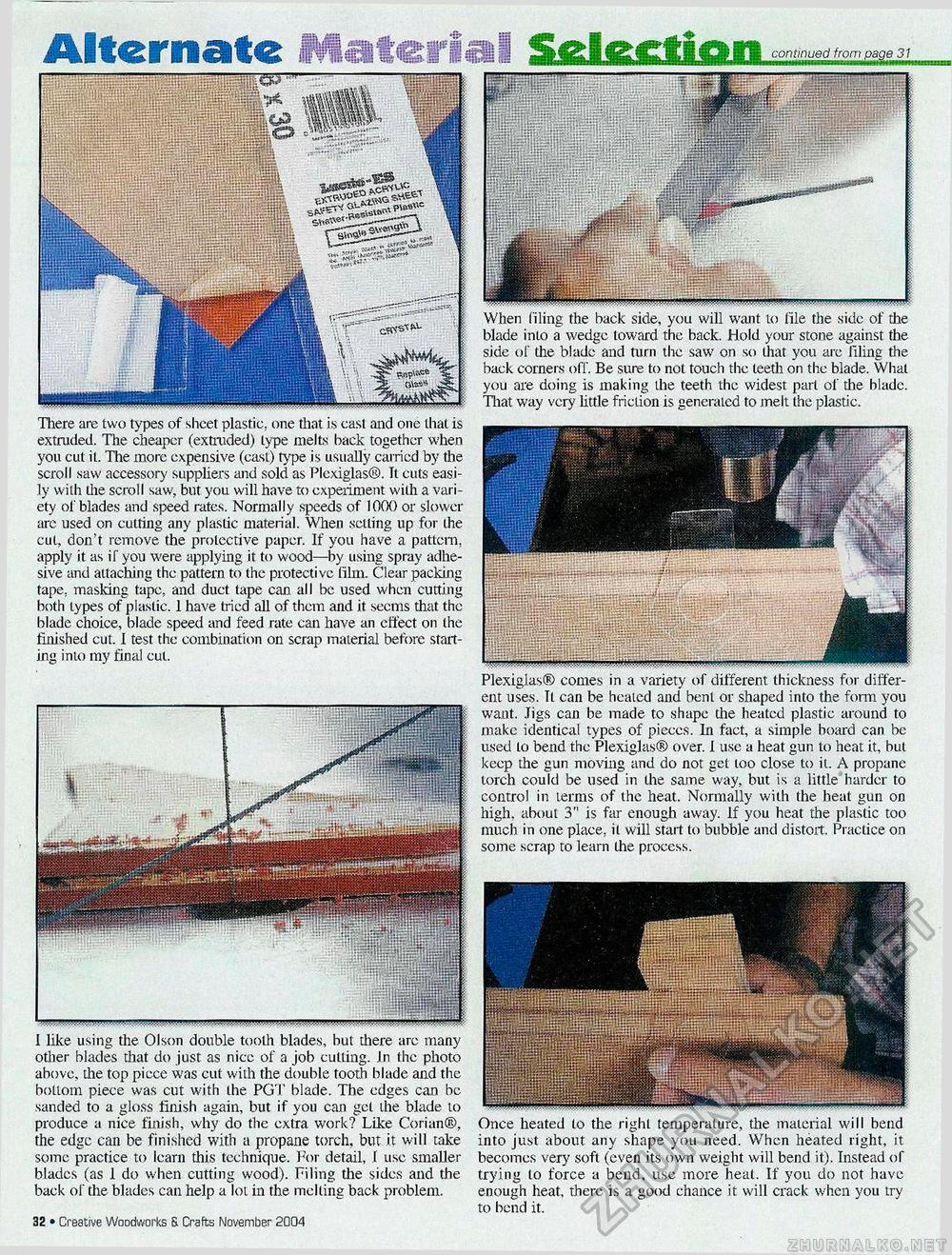

Alternate Material Sglggtion There are two types of sheet plastic, one that is cast and one that is extruded. The cheaper (extruded) type melts back together when you cut it. The more expensive (cast) type is usually carried by the scroll saw accessory suppliers and sold as Plexiglas®. It cuts easily with the scroll saw, but you will have to experiment with a variety of blades and speed rates. Normally speeds of 1000 or slower are used on cutting any plastic material. When setting up for the cut, don't remove the protective paper. If you have a pattern, apply it as if you were applying it to wood—by using spray adhesive and attaching the pattern to the protective film. Clear packing tape, masking tape, and duct tape can all be used when cutting both types of plastic. 1 have tried all of them and it seems that the blade choice, blade speed and feed rate can have an effect on the finished cut. I test the combination on scrap material before starting into my final cut. When filing the back side, you will want to file the side of the blade into a wedge toward the back. Hold your stone against the side of the blade and turn the saw on so that you are Filing the back corners off. Be sure to not touch the teeth on the blade. What you are doing is making the teeth the widest part of the blade. That way very little friction is generated to melt the plastic. Plexiglas® comes in a variety of different thickness for different uses. Tt can be heated and bent or shaped into the form you want. .Tigs can be made to shape the heated plastic around to make identical types of pieces. In fact, a simple board can be used to bend the Plexiglas® over. 1 use a heat gun to heat it, but keep the gun moving and do not get too close to it. A propane torch could be used in the same way, but is a little harder to control in terms of the heat. Normally with the heat gun on high, about 3" is far enough away. If you heat the plastic too much in one place, it will start to bubble and distort. Practice on some scrap to learn the process. I like using the Olson double tooth blades, but there arc many other blades that do just as nice of a job cutting. Jn the photo above, the top piece was cut with the double tooth blade and the bottom piece was cut with the PGT blade. The edges can be sanded to a gloss finish again, but if you can get the blade to produce a nice finish, why do the extra work? Like Corian®, the edge can be finished with a propane torch, but it will take some practice to learn this technique. For detail, I use smaller blades (as 1 do when cutting wood). Filing the sides and the back of the blades can help a lot in the melting back problem. 32 • Creative Woodworks S. Crafts November 2004 Once heated to the right temperature, the material will bend into just about any shape you need. When heated right, it becomes very soft (even its own weight will bend it). Instead of trying to force a bend, use more heal. If you do not have enough heat, there is a good chance it will crack when you try to bend it. |