Creative Woodworks & crafts 2004-11, страница 77

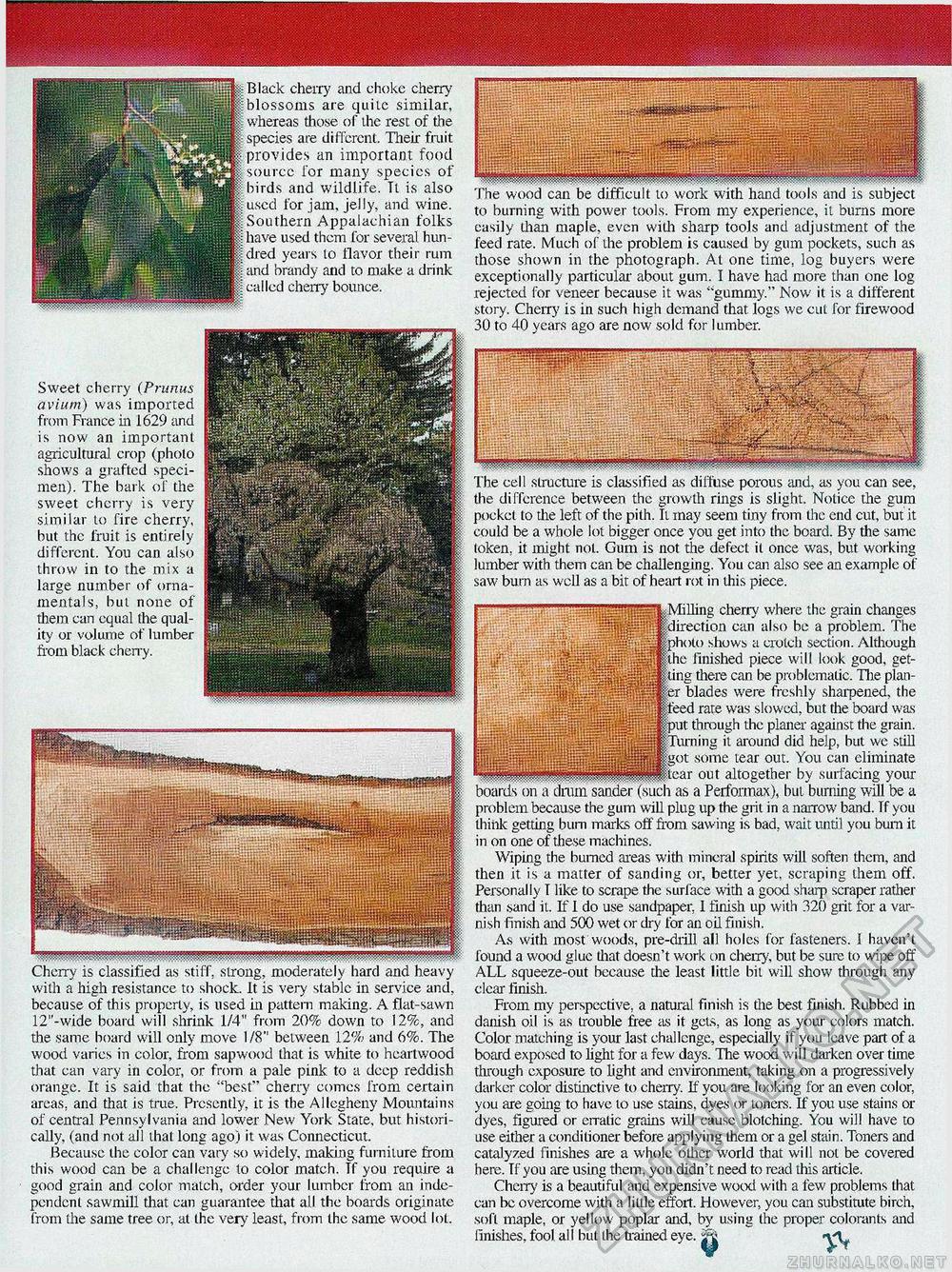

'iMH Itlii^lS'i^-fcMilling cherry where the grain changes tjjj ; direction can also he a problem. The •.. |photo shows a crotch section. Although SI he finisherl niftnp. will look priori oef- :the finished piece will look good, getting there can be problematic. The plan- ler blades were freshly sharpened, the " , |gl" 5teed rate was slowed, but the board was flput through the planer against the grain, -ilillffTurning il around did help, but wc still Igot some tear out. You can eliminate fllear out altogether by surfacing your boards on a drum sander (such as a Performax), but burning will be a problem because the gum will plug up the grit in a narrow band. If you think getting bum marks off from sawing is bad, wait until you bum it in on one of these machines. Wiping the bumcd areas with mineral spirits will soften them, and then it is a matter of sanding or, better yet. scraping them off. Personally 1 like to scrape the surface with a good sharp scraper rather than sand" it. If I do use sandpaper, 1 finish up with 320 grit for a varnish finish and 500 wet or dry for an oil finish. As with most woods, pre-drill all holes for fasteners. 1 haven't found a wood glue (hat doesn't work on cherry, but be sure to wipe off ALL squeeze-out because the least little bit will show through any clear finish. From my perspective, a natural finish is the best finish. Rubbed in danish oil is as trouble free as it gets, as long as your colors match. Color matching is your last challenge, especially if you leave part of a board exposed to light for a few days. The wood will darken over time through exposure to light and environment, taking on a progressively darker color distinctive to cherry. If you are looking for an even color, you are going to have to use stains, dyes or toners. If you use stains or dyes, figured or erratic grains wilt cause blotching. You will have to use either a conditioner before applying them or a gel stain. Toners and catalyzed finishes are a whole other world that will not be covered here. If you are using them, you didn't need to read this article. Cherry is a beautiful and expensive wood with a few problems that can be overcome with a little effort. However, you can substitute birch, soft maple, or yel low poplar and, by using the proper colorants and linishes, fool all but the trained eye. Cherry is classified as stiff, strong, moderately with a high resistance to shock. It is very stable in service because of this property, is used in pattern making. A flat-sawn 12"-wide board will shrink 1/4" from 20% down to 12%, and the same board will only move 1/8" between 12% and 6%. The wood varies in color, from sapwood that is white to hcartwood that can vary in color, or from a pale pink to a deep reddish orange. It is said that the "best" cherry comes from certain areas, and that is true. Presently, it is the Allegheny Mountains of central Pennsylvania and lower New York State, but historically, (and not all that long ago) it was Connecticut. Because the color can vary so widely. making furniture from this wood can be a challenge to color match. Tf you require a good grain and color match, order your lumber from an independent sawmill that can guarantee that all the boards originate from the same tree or, at the very least, from the same wood lot. to burning with power tools. From my experience, it burns more easily than maple, even with sharp tools and adjustment of the feed rate. Much of the problem is caused by gum pockets, such as those shown in the photograph. At one time, log buyers were exceptionally particular about gum. I have had more than one log rejected for veneer because it was "gummy." Now it is a different story. Cherry is in such high demand that logs we cut for firewood 30 to 40 years ago are now sold for lumber. Sweet cherry (Primus avium) was imported from France in 1629 and is now an important agricultural crop (photo shows a grafted specimen). The bark of the sweet cherry is very similar to fire cherry, but the fruit is entirely different. You can also throw in to the mix a large number of ornamentals, but none of them can equal the quality or volume of lumber from black cherry. The cell structure is classified as diffuse porous and, as you can see, the difference between the growth rings is slight. Notice the gum pocket to the left of the pith. It may seem tiny from the end cut, but it could be a whole lot bigger once you get into the board. By the same token, it might not. Gum is not the defect it once was, but working lumber with them can be challenging. You can also see an example of saw burn as well as a bit of heart rot in this piece. Black cherry and choke cherry ossoms are quite similar, those of the rest of the are different. Their fruit ides an important food rcc for many species of rds and wildlife. Tt is also used for jam, jelly, and wine. Southern Appalachian folks used them for several hun-years to flavor their rum brandy and to make a drink led cherry bounce. |