Creative Woodworks & Crafts-050-1998-winter, страница 22

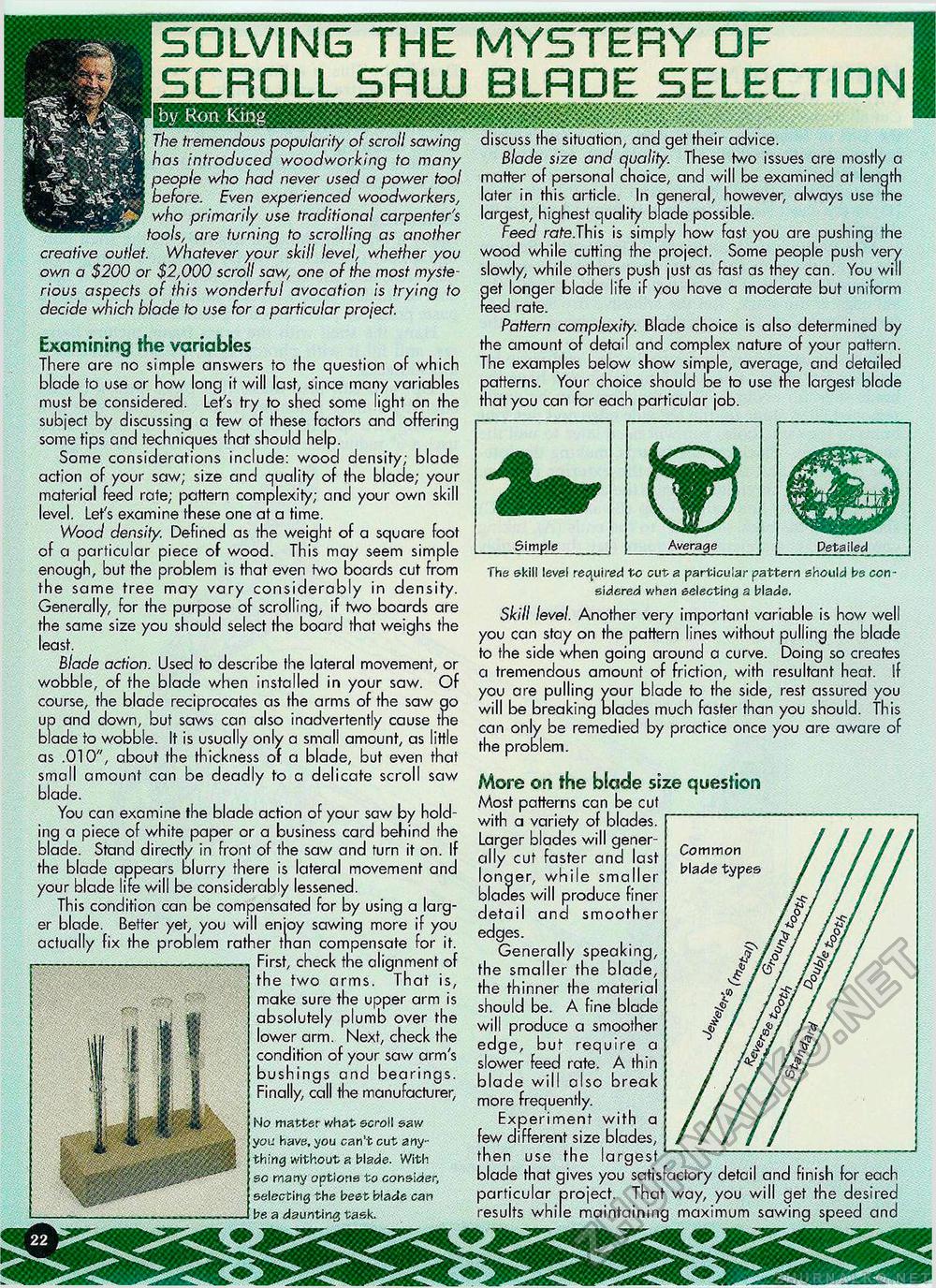

SOLVING THE SCROLL SRUL) The tremendous popularity of scroll sawing has introduced woodworking to many people who had never used a power tool before. Even experienced woodworkers, who primarily use traditional carpenter's tools, are turning to scrolling as another creative outlet. Whatever your skill level, whether you own a $200 or $2,000 scroll saw, one of the most mysterious aspects of this wonderful avocation is trying to decide which blade to use for a particular project. Examining the variables There are no simple answers to the question of which blade to use or how long it will last, since many variables must be considered. Lefs try to shed some light on the subject by discussing a few of these factors and offering some tips and techniques that should help. Some considerations include: wood density; blade action of your saw; size and quality of the blade; your material feed rate; pattern complexity; and your own skill level. Let's examine these one at a time. Wood density. Defined as the weight of a square foot of a particular piece of wood. This may seem simple enough, but the problem is that even two boards cut from the same tree may vary considerably in density. Generally, for the purpose of scrolling, if two boards are the same size you should select the board that weighs the least. Blade action. Used to describe the lateral movement, or wobble, of the blade when installed in your saw. Of course, the blade reciprocates as the arms of the saw go up and down, but saws can also inadvertently cause trie blade to wobble. It is usually only a small amount, as little as .010", about the thickness of a blade, but even that small amount can be deadly to a delicate scroll saw blade. You can examine the blade action of your saw by holding a piece of white paper or a business card behind the blade. Stand directly in front of the saw and turn it on. If the blade appears blurry there is lateral movement and your blade life will be considerably lessened. This condition can be compensated for by using a larger blade. Better yet you will enioy sawing more if you actually fix the problem rather than compensate for it. First, check tne alignment of the two arms. That is, make sure the upper arm is absolutely plumb over the lower arm. Next, check the condition of your saw arm's bushings and bearings. Finally, call the manufacturer, No matter what scroll saw you have, you can't cut anything without a blade. With so many options to consider, selecting the best blade can be a daunting task. MYSTERY OF BLROE SELECTION discuss the situation, and get their advice. Blade size and quality. These two issues are mostly a matter of personal choice, and will be examined at length later in this article. In general, however, always use tne largest, highest quality blade possible. Feed rate.This is simply how fast you are pushing the wood while cutting the project. Some people push very slowly, while others push just as fast as they can. You will get longer blade life if you have a moderate but uniform reed rate. Pattern complexify. Blade choice is also determined by the amount of detail and complex nature of your pattern. The examples below show simple, average, and detailed patterns. Your choice should be to use the largest blade that you can for each particular job. Simple Average Detailed The ©kill level required to cut a particular pattern should be con sidered when selecting a blade. Skill level. Another very important variable is how well you can stay on the pattern lines without pulling the blade to the side when going around a curve. Doing so creates a tremendous amount of friction, with resultant heat. If you are pulling your blade to the side, rest assured you will be breaking blades much faster than you should. This can only be remedied by practice once you are aware of the problem. More on the blade size question Most patterns can be cut with a variety of blades. Larger blades will generally cut faster and last longer, while smaller blades will produce finer detail and smoother edges. Generally speaking, the smaller the blade, the thinner the material should be. A fine blade will produce a smoother edge, but require a slower feed rate. A thin blade will also break more frequently. Experiment with a few different size blades, then use the largest blade that gives you satisfactory detail and finish for each particular project. That way, you will get the desired results while maintaining maximum sawing speed and blade types |