Creative Woodworks & Crafts-050-1998-winter, страница 24

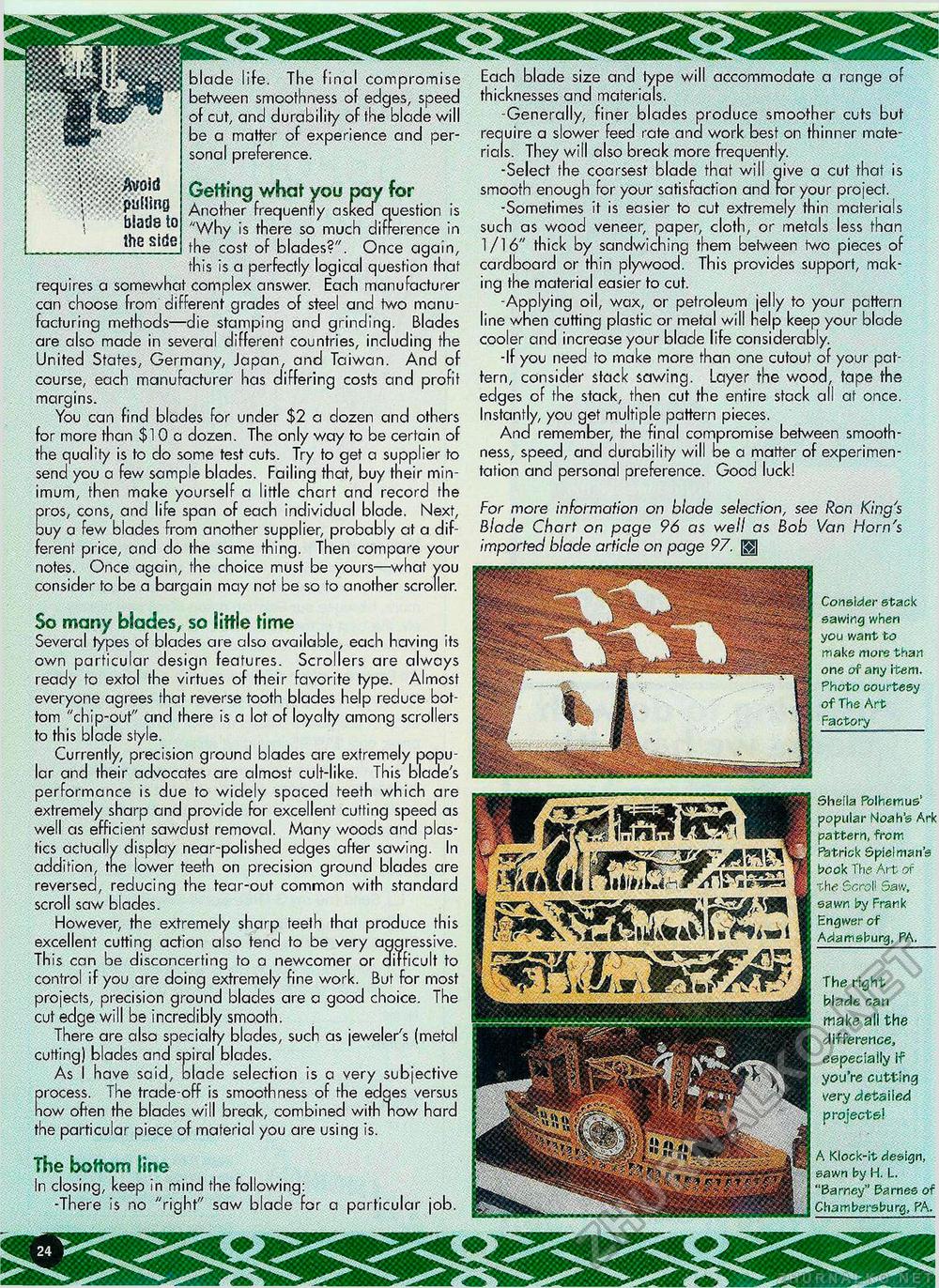

isilli™ m^SF^im blade lire. Ihe tinal compromise between smoothness of edges, speed of cut, and durability of the blade will be a matter of experience and personal preference. Getting what you pay for Another frequently asked question is "Why is there so much difference in the cost of blades?". Once again, this is a perfectly logical question that requires a somewhat complex answer. Each manufacturer can choose from different grades of steel and two manufacturing methods—die stamping and grinding. Blades are also made in several different countries, including the United States, Germany, Japan, and Taiwan. And of course, each manufacturer has differing costs and profit margins. You can find blades for under $2 a dozen and others for more than $10 a dozen. The only way to be certain of the quality is to do some test cuts. Try to get a supplier to send you a few sample blades. Failing that, buy their minimum, then make yourself a little chart and record the pros, cons, and life span of each individual blade. Next, buy a few blades from another supplier, probably at a different price, and do the same thing. Then compare your notes. Once again, the choice must be yours—what you consider to be a bargain may not be so to another scroller. So many blades, so little time Several types of blades are also available, each having its own particular design features. Scrollers are always ready to extol the virtues of their favorite type. Almost everyone agrees that reverse tooth blades help reduce bottom "chip-out" and there is a lot of loyalty among scrollers to this blade style. Currently, precision ground blades are extremely popular and their advocates are almost cult-like. This blade's performance is due to widely spaced teeth which are extremely sharp and provide for excellent cutting speed as well as efficient sawdust removal. Many woods and plastics actually display near-polished edges after sawing. In addition, the lower teeth on precision ground blades are reversed, reducing the tear-out common with standard scroll saw blades. However, the extremely sharp teeth that produce this excellent cutting action also tend to be very aggressive. This can be disconcerting to a newcomer or difficult to control if you are doing extremely fine work. But for most projects, precision ground blades are a good choice. The cut edge will be incredibly smooth. There are also specialty blades, such as jeweler's (metal cutting) blades and spiral blades. As I have said, blade selection is a very subjective process. The trade-off is smoothness of the edges versus now often the blades will break, combined with now hard the particular piece of material you are using is. The bottom tine In closing, keep in mind the following: -There is no "right" saw blade for a particular job. Each blade size and type will accommodate a range of thicknesses and materials. -Generally, finer blades produce smoother cuts but require a slower feed rate ana work best on thinner materials. They will also break more frequently. -Select the coarsest blade that will give a cut that is smooth enough for your satisfaction and for your project. -Sometimes it is easier to cut extremely thin materials such as wood veneer, paper, cloth, or metals less than 1/16" thick by sandwiching them between two pieces of cardboard or thin plywood. This provides support, making the material easier to cut. -Applying oil, wax, or petroleum jelly to your pattern line when cutting plastic or metal will help keep your blade cooler and increase your blade life considerably. -If you need to make more than one cutout of your pattern, consider stack sawing. Layer the wood, tape the edges of the stack, then cut the entire stack all at once. Instantly, you get multiple pattern pieces. And remember, the final compromise between smoothness, speed, and durability will be a matter of experimentation and personal preference. Good luck! For more information on blade selection, see Ron King's Blade Chart on page 96 as well as Bob Van Horn's imported blade article on page 97. [S5| Consider stack sawing when you want to make more than one of any item. Photo courtesy of The Art Factory Sheila Polhemus' popular Noah's Ark pattern, from Patrick Spielman's book The Art or % he Scroll Saw, sawn by Frank Engwer of Adamsburg, PA, The right blade can make all the difference, especially if you're cutting very de tailed projects! A Klock-it design, sawn by H. L. "Barney" Barnes of Chambersburg, PA. |