Creative Woodworks & Crafts-050-1998-winter, страница 38

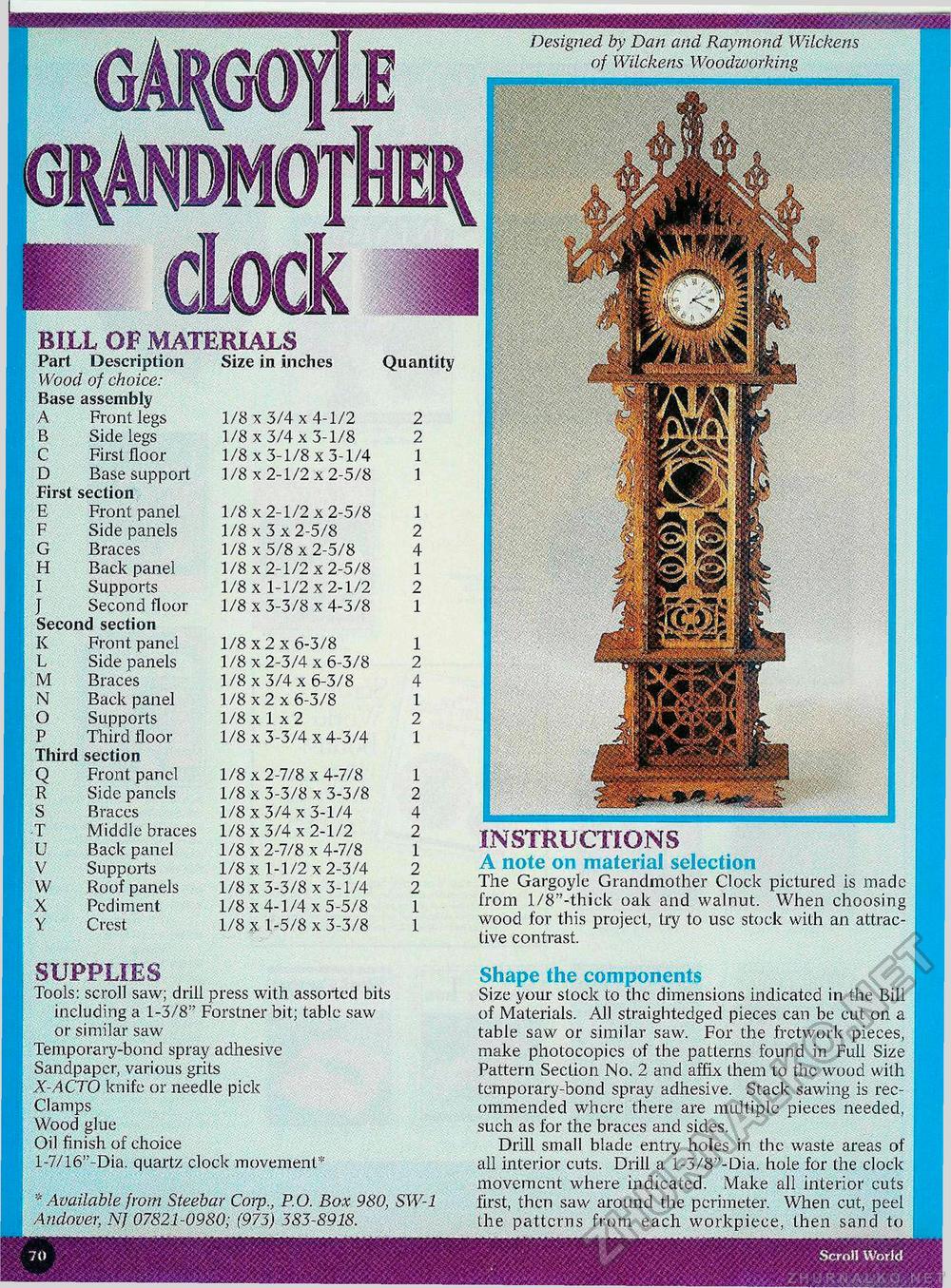

Scroll World * Available from Steebar Corp., P.O. Box 980, SW-1 Andover, NJ 07821-0980; (973) 383-8918. Size in inches BILL OF MATERIALS Part Description Wood of choice: Base assembly A Front legs B Side legs C First floor D Base support First section E Front panel F Side panels G Braces H Back panel I Supports J Second floor Second section K Front panel L Side panels M Braces N Back panel O Supports P Third floor Third section Q Front panel 1/8 x 2-7/8 x 4-7/8 R Side panels 1/8 x 3-3/8 x 3-3/8 S Braces 1/8 x 3/4 x 3-1/4 -T Middle braces 1/8 x 3/4 x 2-1/2 U Back panel 1/8 x 2-7/8 x 4-7/8 V Supports 1/8 x 1-1/2 x 2-3/4 W Roof panels 1/8 x 3-3/8 x 3-1/4 X Pediment 1/8x4-1/4x5-5/8 Y Crest 1/8 x 1-5/8 x 3-3/8 Quantity 1/8x3/4x4-1/2 1/8 x 3/4x3-1/8 1/8x3-1/8x3-1/4 1/8 x 2-1/2x2-5/8 1/8x2-1/2x2-5/8 1/8x3x2-5/8 1/8x5/8x2-5/8 1/8x2-1/2x2-5/8 1/8x1-1/2x2-1/2 1/8x3-3/8x4-3/8 1/8x2x6-3/8 1/8x2-3/4x6-3/8 1/8x3/4x6-3/8 1/8x2x6-3/8 1/8x1x2 1/8x3-3/4x4-3/4 SUPPLIES Tools: scroll saw; drill press with assorted bits including a 1-3/8" Forstner bit; table saw or similar saw Temporary-bond spray adhesive Sandpaper, various grits X-ACTO knife or needle pick Clamps Wood glue Oil finish of choice l-7/16"-Dia. quartz clock movement* Shape the components Size your stock to the dimensions indicated in the Bill of Materials. All straightedged pieces can be cut on a table saw or similar saw. For the fretwork pieces, I make photocopies of the patterns found in Full Size Pattern Section No. 2 and affix them to the wood with temporary-bond spray adhesive. Stack sawing is rec- I ommended where there are multiple pieces needed, 1 such as for the braces and sides. Drill small blade entry holes in the waste areas of all interior cuts. Drill a l-3/8"-Dia. hole for the clock | movement where indicated. Make all interior cuts I first, then saw around the perimeter. When cut, peel 1 the patterns from each workpieee, then sand to INSTRUCTIONS A note on material selection The Gargoyle Grandmother Clock pictured is made from l/8"-thick oak and walnut. When choosing wood for this project, try to use stock with an attractive contrast. Designed by Dan and Raymond Wilckens of Wilckens Woodworking |