Creative Woodworks & Crafts-059-1998-Fall, страница 48

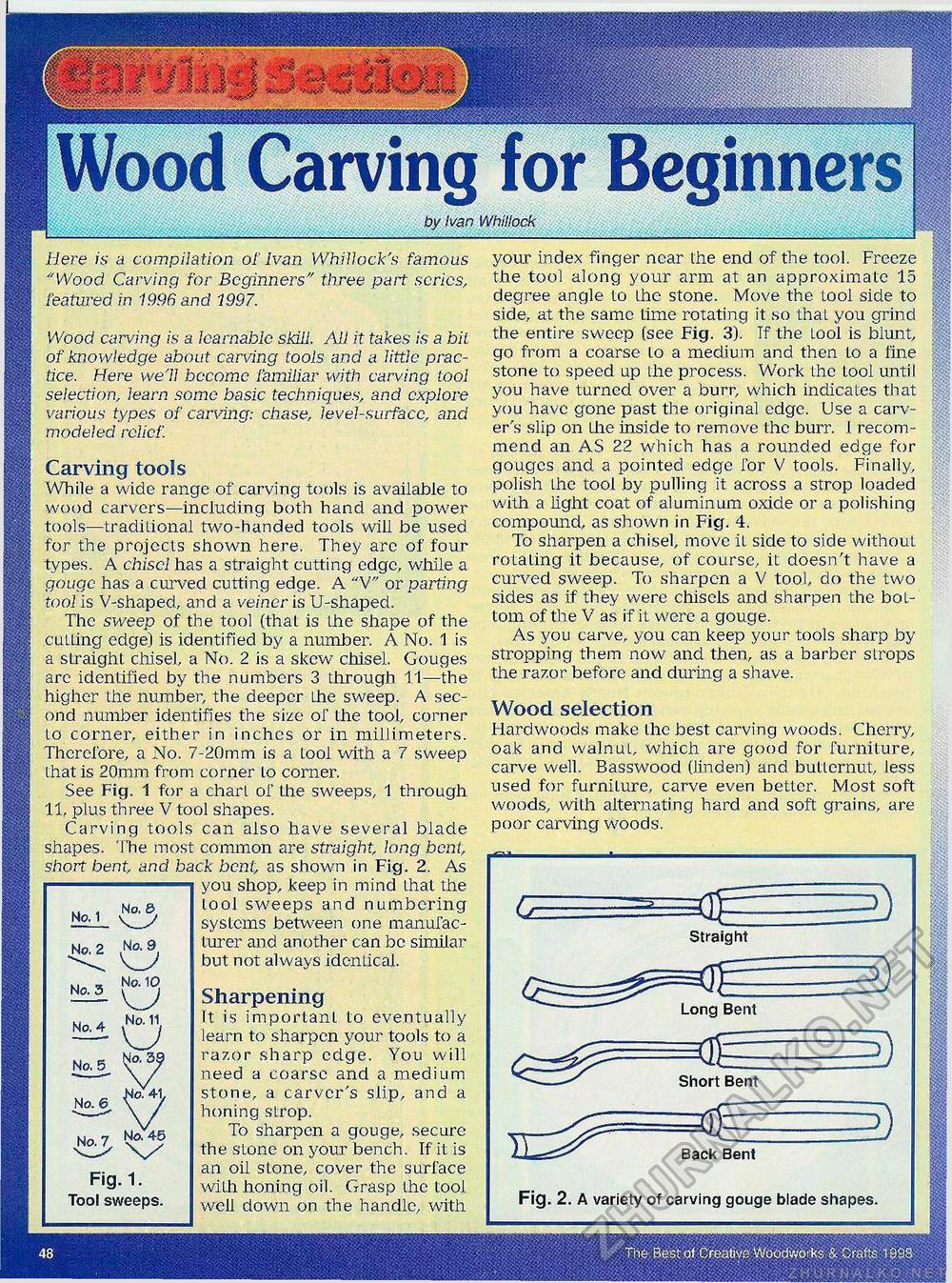

by Ivan Whlllock Here is a compilation of Ivan Whillock's famous "Wood Carving for Beginners" three part series, Featured in 1996 and 1997. Wood carving is a lcarnablc skill. All it takes is a bit of knowledge about carving tools and a little practice. Here we'll hccome familiar with carving tool selection, learn some basic techniques, and explore various types of carving: chase, level-surfaceand modeled relief. Carving tools While a wide range of carving tools is available to wood carvers—including both hand and power tools—traditional two-handed tools will be used for the projects shown here. They arc of four types. A chiscl has a straight cutting edge, while a gouge has a curved cutting edge. A "V" or parting tool is V-shaped, and a veincr is U-shaped. The sweep of the tool (that is lhe shape of the culling edge) is identified by a number. A No. 1 is a straight chisel, a No. 2 is a skew chisel. Gouges arc identified by the numbers 3 through 11—the higher the number, the deeper Lhe sweep. A second number identifies the size of the tool, corner Lo corner, either in inches or in millimeters. Therefore, a No. 7-20mm is a Lool with a 7 sweep lhat is 20mm from corner Lo corner. See Fig. 1 for a charl of Lhe sweeps, 1 through 11, plus three V tool shapes. Carving tools can also have several blade shapes. The most common are straight, long bent short bent, and back bent, as shown in Fig. 2. As you shop, keep in mind Lhat the lool sweeps and numbering systems between one manufacturer and another can be similar but not always identical. Sharpening It is important to eventually learn to sharpen your tools to a razor sharp edge. You will need a coarsc and a medium stone, a carver's slip, and a honing strop. To sharpen a gouge, secure the stone on your bench. If it is an oil slone, cover the surface with honing oil. Grasp the tool well down on the handle, with No. o No. 1 No. 9 No. 2 No. 10 No. 3 No. 11 No. 4 No. 5 No. 6 No. 45 No. 7 Tool sweeps. your index finger near lhe end of the tool. Freeze the tool along your arm at an approximate 15 degree angle lo the stone. Move the Lool side to side, at the same Lime rotating it so that you grind the entire sweep (see Fig. 3). If the lool is blunt, go from a coarse lo a medium and then lo a fine stone to speed up the process. Work the lool until you have turned over a burr, which indicates that you have gone past the original edge. Use a carver's slip on Lhe inside to remove the burr. 1 recommend an AS 22 which has a rounded edge for gouges and a pointed edge for V tools. Finally, polish lhe tool by pulling it across a strop loaded with a light coat of aluminum oxide or a polishing compound, as shown in Fig. 4. To sharpen a chisel, move it side to side without rotating it because, of coursc, it doesn't have a curved sweep. To sharpen a V tool, do the two sides as if they were chisels and sharpen the bol-tom of the V as if it were a gouge. As you carve, you can keep your tools sharp by stropping them now and then, as a barber strops the razor before and during a shave. Wood selection Hardwoods make lhe best carving woods. Cherry, oak and walnul, which are good for furniture, carve well. Basswood (linden) and buLlernut, less used for furniture, carve even better. Most soft woods, with alternating hard and soft grains, are poor carving woods. Straight Long Bent Short Bent Back Bent Fig. 2. A variety of carving gouge blade shapes. |