Popular Woodworking 2000-02 № 113, страница 25

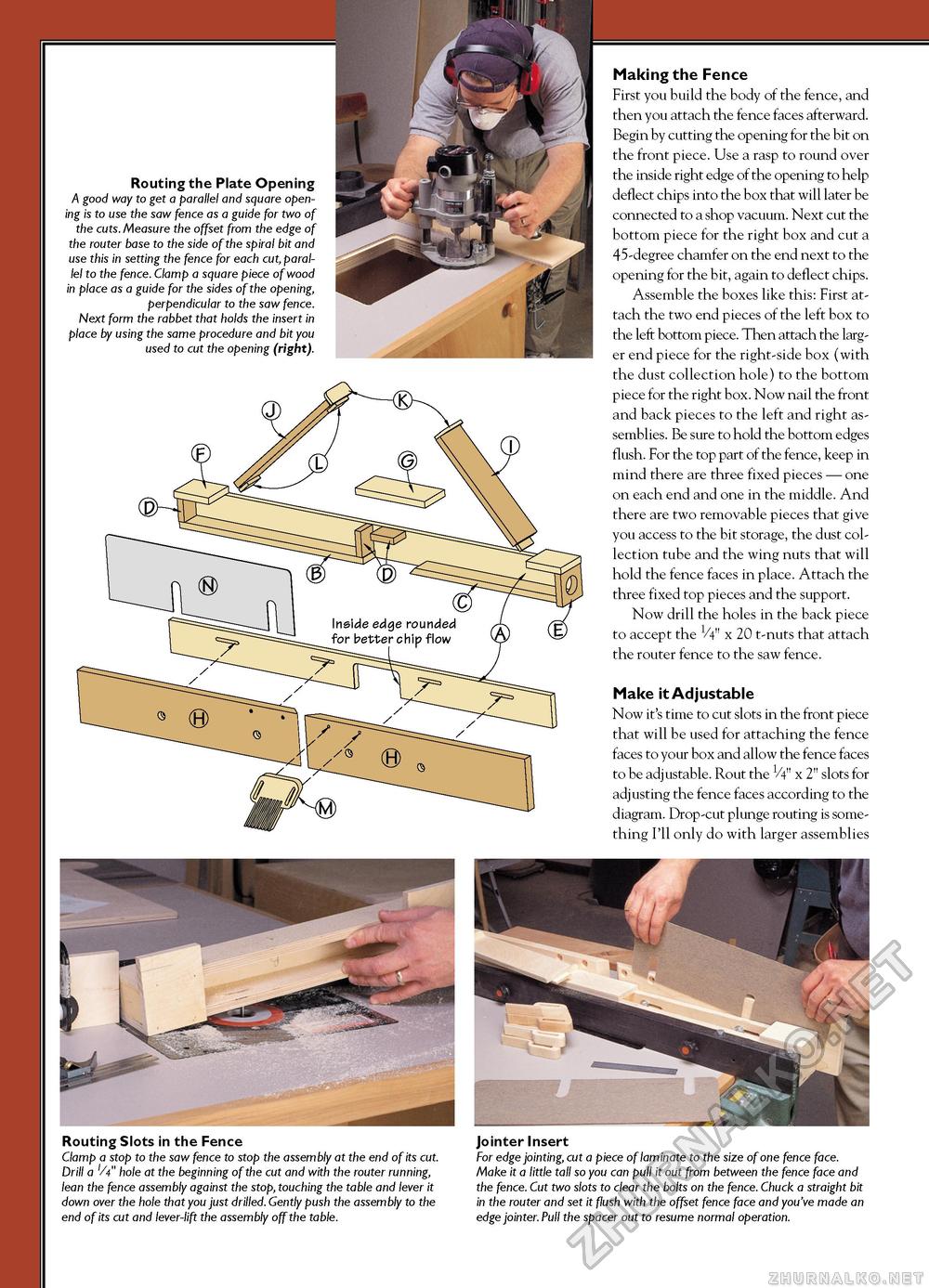

Routing the Plate Opening A good way to get a parallel and square opening is to use the saw fence as a guide for two of the cuts. Measure the offset from the edge of the router base to the side of the spiral bit and use this in setting the fence for each cut, parallel to the fence. Clamp a square piece of wood in place as a guide for the sides of the opening, perpendicular to the saw fence. Next form the rabbet that holds the insert in place by using the same procedure and bit you used to cut the opening (right). Making the Fence First you build the body of the fence, and then you attach the fence faces afterward. Begin by cutting the opening for the bit on the front piece. Use a rasp to round over the inside right edge of the opening to help deflect chips into the box that will later be connected to a shop vacuum. Next cut the bottom piece for the right box and cut a 45-degree chamfer on the end next to the opening for the bit, again to deflect chips. Assemble the boxes like this: First attach the two end pieces of the left box to the left bottom piece. Then attach the larger end piece for the right-side box (with the dust collection hole) to the bottom piece for the right box. Now nail the front and back pieces to the left and right assemblies. Be sure to hold the bottom edges flush. For the top part of the fence, keep in mind there are three fixed pieces — one on each end and one in the middle. And there are two removable pieces that give you access to the bit storage, the dust collection tube and the wing nuts that will hold the fence faces in place. Attach the three fixed top pieces and the support. Now drill the holes in the back piece to accept the V4" x 20 t-nuts that attach the router fence to the saw fence. Make it Adjustable Now it's time to cut slots in the front piece that will be used for attaching the fence faces to your box and allow the fence faces to be adjustable. Rout the V4" x 2" slots for adjusting the fence faces according to the diagram. Drop-cut plunge routing is something I'll only do with larger assemblies Routing Slots in the Fence Clamp a stop to the saw fence to stop the assembly at the end of its cut. Drill a 'A" hole at the beginning of the cut and with the router running, lean the fence assembly against the stop, touching the table and lever it down over the hole that you just drilled. Gently push the assembly to the end of its cut and lever-lift the assembly off the table. Jointer Insert For edge jointing, cut a piece of laminate to the size of one fence face. Make it a little tall so you can pull it out from between the fence face and the fence. Cut two slots to clear the bolts on the fence. Chuck a straight bit in the router and set it flush with the offset fence face and you've made an edge jointer. Pull the spacer out to resume normal operation. |