Popular Woodworking 2000-02 № 113, страница 56

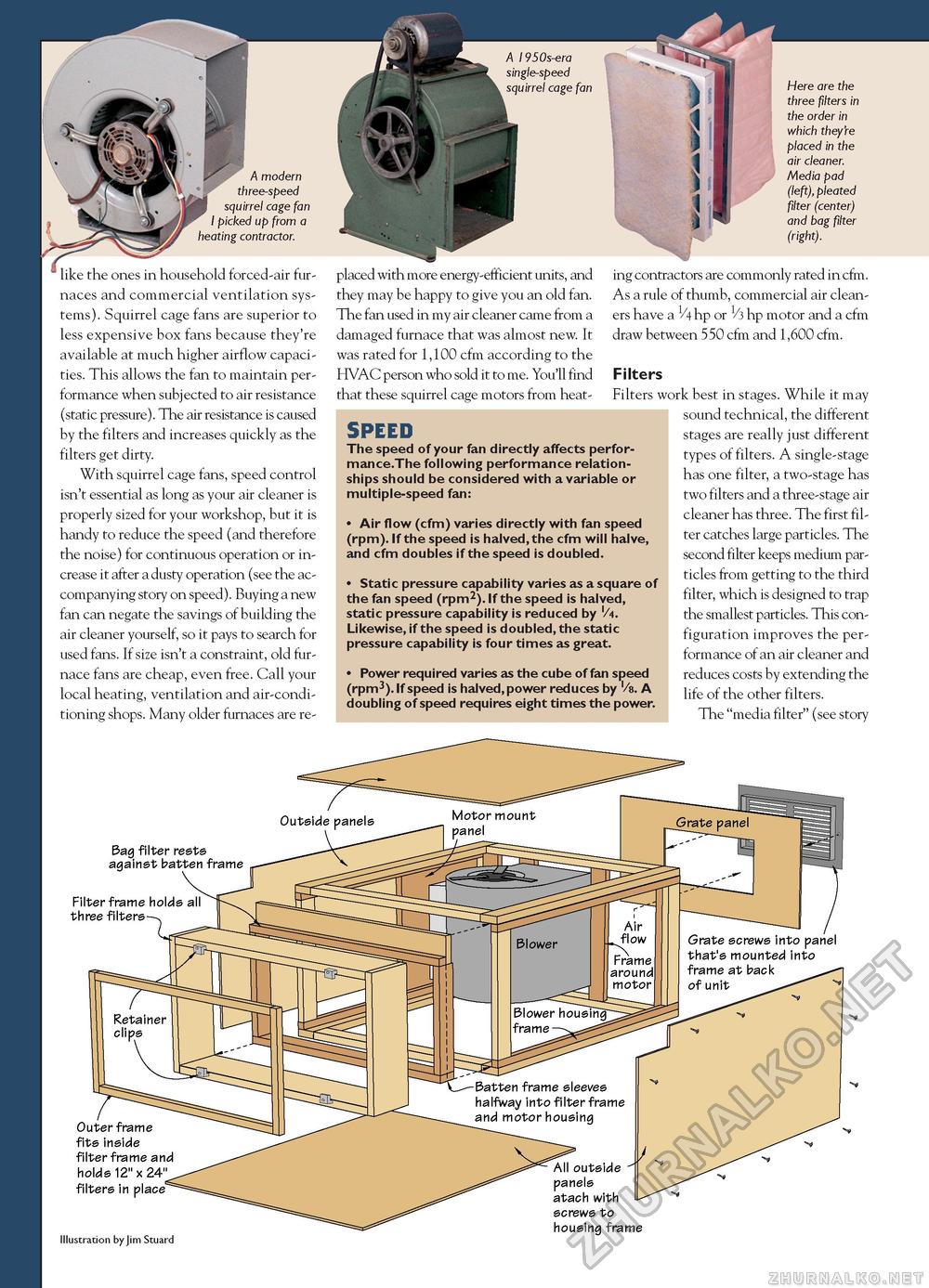

A modern three-speed squirrel cage fan I picked up from a heating contractor. ' like the ones in household forced-air furnaces and commercial ventilation systems). Squirrel cage fans are superior to less expensive box fans because they're available at much higher airflow capacities. This allows the fan to maintain performance when subjected to air resistance (static pressure). The air resistance is caused by the filters and increases quickly as the filters get dirty. With squirrel cage fans, speed control isn't essential as long as your air cleaner is properly sized for your workshop, but it is handy to reduce the speed (and therefore the noise) for continuous operation or increase it after a dusty operation (see the accompanying story on speed). Buying a new fan can negate the savings of building the air cleaner yourself, so it pays to search for used fans. If size isn't a constraint, old furnace fans are cheap, even free. Call your local heating, ventilation and air-conditioning shops. Many older furnaces are re- A I950s-era single-speed squirrel cage fan placed with more energy-efficient units, and they may be happy to give you an old fan. The fan used in my air cleaner came from a damaged furnace that was almost new. It was rated for 1,100 cfm according to the HVAC person who sold it to me. You'll find that these squirrel cage motors from heat- SPEED The speed of your fan directly affects perfor-mance.The following performance relationships should be considered with a variable or multiple-speed fan: • Air flow (cfm) varies directly with fan speed (rpm). If the speed is halved,the cfm will halve, and cfm doubles if the speed is doubled. • Static pressure capability varies as a square of the fan speed (rpm2). If the speed is halved, static pressure capability is reduced by '/4. Likewise, if the speed is doubled, the static pressure capability is four times as great. • Power required varies as the cube of fan speed (rpm3). If speed is halved, power reduces by '/s. A doubling of speed requires eight times the power. Here are the three filters in the order in which they're placed in the air cleaner. Media pad (left), pleated filter (center) and bag filter (right). ing contractors are commonly rated in cfm. As a rule of thumb, commercial air cleaners have a hp or 1/3 hp motor and a cfm draw between 550 cfm and 1,600 cfm. Filters Filters work best in stages. While it may sound technical, the different stages are really just different types of filters. A single-stage has one filter, a two-stage has two filters and a three-stage air cleaner has three. The first filter catches large particles. The second filter keeps medium particles from getting to the third filter, which is designed to trap the smallest particles. This configuration improves the performance of an air cleaner and reduces costs by extending the life of the other filters. The "media filter" (see story Bag filter rests against batten frame Filter frame holds all three filters Outer frame fits inside filter frame and holds 12" x 24" filters in place Illustration by Jim Stuard outside panels atach with screws to housing frame |