Popular Woodworking 2000-02 № 113, страница 57

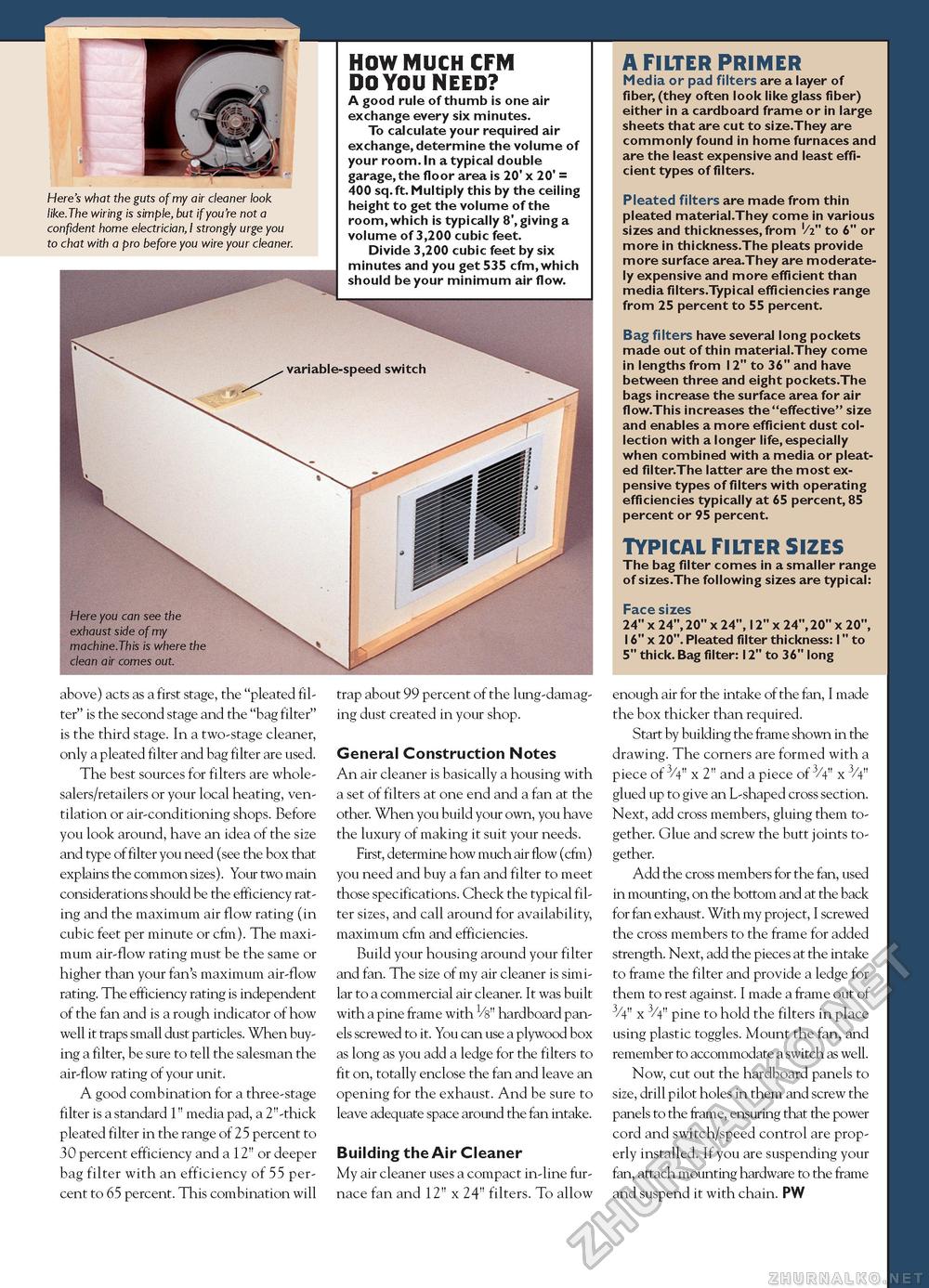

Here's what the guts of my air cleaner look like.The wiring is simple, but if you're not a confident home electrician, I strongly urge you to chat with a pro before you wire your cleaner. HOW MUCH CFM DO YOU NEED? A good rule of thumb is one air exchange every six minutes. To calculate your required air exchange, determine the volume of your room. In a typical double garage, the floor area is 20' x 20' = 400 sq.ft. Multiply this by the ceiling height to get the volume of the room, which is typically 8', giving a volume of 3,200 cubic feet. Divide 3,200 cubic feet by six minutes and you get 535 cfm, which should be your minimum air flow. Here you can see the exhaust side of my machine.This is where the clean air comes out. above) acts as a first stage, the "pleated filter" is the second stage and the "bag filter" is the third stage. In a two-stage cleaner, only a pleated filter and bag filter are used. The best sources for filters are wholesalers/retailers or your local heating, ventilation or air-conditioning shops. Before you look around, have an idea of the size and type of filter you need (see the box that explains the common sizes). Your two main considerations should be the efficiency rating and the maximum air flow rating (in cubic feet per minute or cfm). The maximum air-flow rating must be the same or higher than your fan's maximum air-flow rating. The efficiency rating is independent of the fan and is a rough indicator of how well it traps small dust particles. When buying a filter, be sure to tell the salesman the air-flow rating of your unit. A good combination for a three-stage filter is a standard 1" media pad, a 2"-thick pleated filter in the range of 25 percent to 30 percent efficiency and a 12" or deeper bag filter with an efficiency of 55 percent to 65 percent. This combination will trap about 99 percent of the lung-damaging dust created in your shop. General Construction Notes An air cleaner is basically a housing with a set of filters at one end and a fan at the other. When you build your own, you have the luxury of making it suit your needs. First, determine how much air flow (cfm) you need and buy a fan and filter to meet those specifications. Check the typical filter sizes, and call around for availability, maximum cfm and efficiencies. Build your housing around your filter and fan. The size of my air cleaner is similar to a commercial air cleaner. It was built with a pine frame with Vs" hardboard panels screwed to it. You can use a plywood box as long as you add a ledge for the filters to fit on, totally enclose the fan and leave an opening for the exhaust. And be sure to leave adequate space around the fan intake. Building the Air Cleaner My air cleaner uses a compact in-line furnace fan and 12" x 24" filters. To allow A FILTER PRIMER Media or pad filters are a layer of fiber, (they often look like glass fiber) either in a cardboard frame or in large sheets that are cut to size.They are commonly found in home furnaces and are the least expensive and least efficient types of filters. Pleated filters are made from thin pleated material.They come in various sizes and thicknesses, from '/2" to 6" or more in thickness.The pleats provide more surface area.They are moderately expensive and more efficient than media filters.Typical efficiencies range from 25 percent to 55 percent. Bag filters have several long pockets made out of thin material.They come in lengths from 12" to 36" and have between three and eight pockets.The bags increase the surface area for air flow.This increases the "effective" size and enables a more efficient dust collection with a longer life, especially when combined with a media or pleated filter.The latter are the most expensive types of filters with operating efficiencies typically at 65 percent, 85 percent or 95 percent. Typical filter sizes The bag filter comes in a smaller range of sizes.The following sizes are typical: Face sizes 24" x 24", 20" x 24", 12" x 24", 20" x 20", 16" x 20".Pleated filter thickness: I" to 5" thick. Bag filter: I2" to 36" long enough air for the intake of the fan, I made the box thicker than required. Start by building the frame shown in the drawing. The corners are formed with a piece of 3/4" x 2" and a piece of 3/4" x 3/4" glued up to give an L-shaped cross section. Next, add cross members, gluing them together. Glue and screw the butt joints together. Add the cross members for the fan, used in mounting, on the bottom and at the back for fan exhaust. With my project, I screwed the cross members to the frame for added strength. Next, add the pieces at the intake to frame the filter and provide a ledge for them to rest against. I made a frame out of 3/4" x 3/4" pine to hold the filters in place using plastic toggles. Mount the fan, and remember to accommodate a switch as well. Now, cut out the hardboard panels to size, drill pilot holes in them and screw the panels to the frame, ensuring that the power cord and switch/speed control are properly installed. If you are suspending your fan, attach mounting hardware to the frame and suspend it with chain. pw |