Popular Woodworking 2000-04 № 114, страница 10

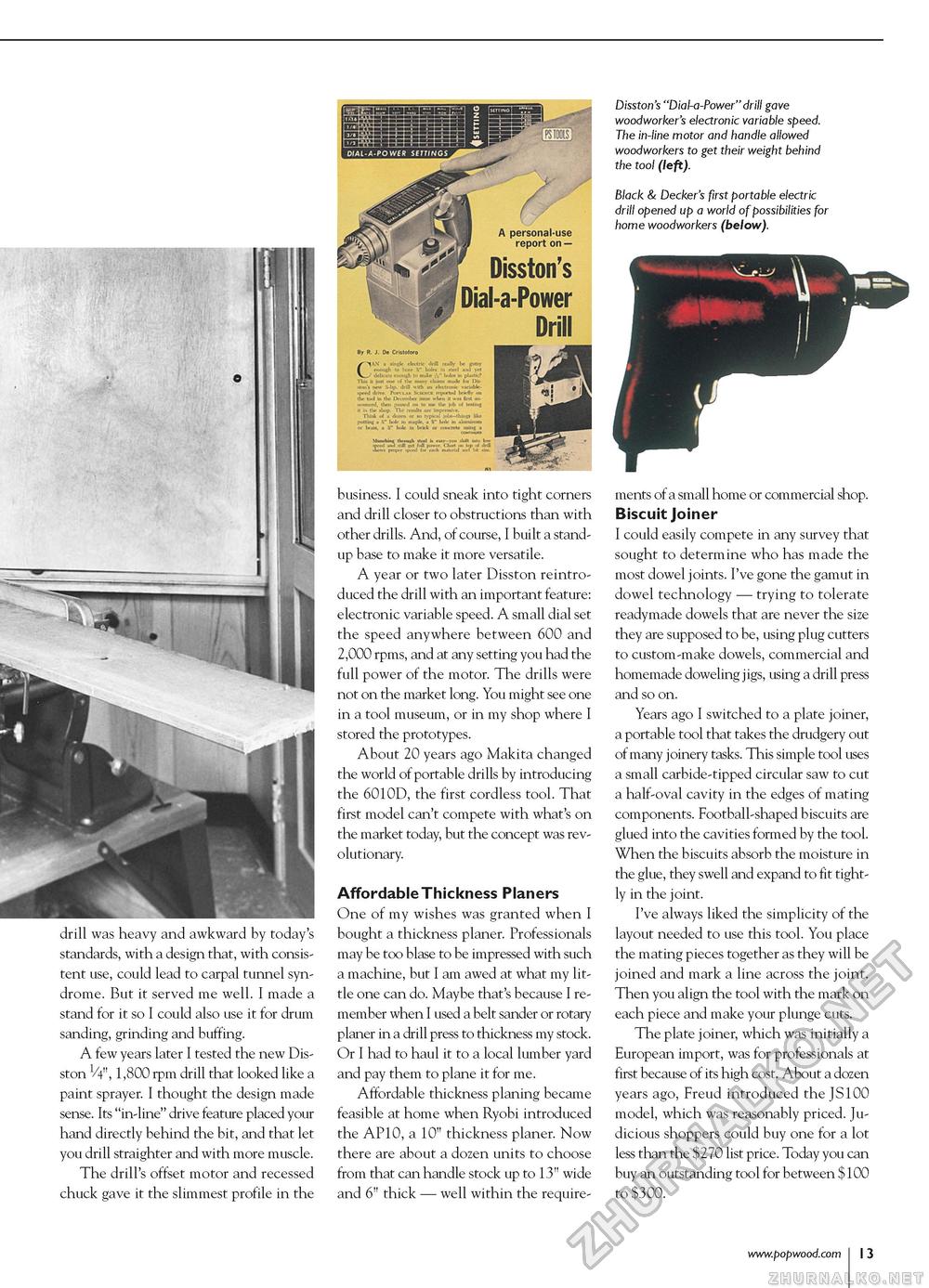

drill was heavy and awkward by today's standards, with a design that, with consistent use, could lead to carpal tunnel syndrome. But it served me well. I made a stand for it so I could also use it for drum sanding, grinding and buffing. A few years later I tested the new Dis-ston V4", 1,800 rpm drill that looked like a paint sprayer. I thought the design made sense. Its "in-line" drive feature placed your hand directly behind the bit, and that let you drill straighter and with more muscle. The drill's offset motor and recessed chuck gave it the slimmest profile in the Disston's "Dial-a-Power" drill gave woodworker's electronic variable speed. The in-line motor and handle allowed woodworkers to get their weight behind the tool (left). Black & Decker's first portable electric drill opened up a world of possibilities for home woodworkers (below). MS , f business. I could sneak into tight corners and drill closer to obstructions than with other drills. And, of course, I built a stand-up base to make it more versatile. A year or two later Disston reintro-duced the drill with an important feature: electronic variable speed. A small dial set the speed anywhere between 600 and 2,000 rpms, and at any setting you had the full power of the motor. The drills were not on the market long. You might see one in a tool museum, or in my shop where I stored the prototypes. About 20 years ago Makita changed the world of portable drills by introducing the 6010D, the first cordless tool. That first model can't compete with what's on the market today, but the concept was revolutionary. Affordable Thickness Planers One of my wishes was granted when I bought a thickness planer. Professionals may be too blase to be impressed with such a machine, but I am awed at what my little one can do. Maybe that's because I remember when I used a belt sander or rotary planer in a drill press to thickness my stock. Or I had to haul it to a local lumber yard and pay them to plane it for me. Affordable thickness planing became feasible at home when Ryobi introduced the AP10, a 10" thickness planer. Now there are about a dozen units to choose from that can handle stock up to 13" wide and 6" thick — well within the require- ments of a small home or commercial shop. Biscuit Joiner I could easily compete in any survey that sought to determine who has made the most dowel joints. I've gone the gamut in dowel technology — trying to tolerate readymade dowels that are never the size they are supposed to be, using plug cutters to custom-make dowels, commercial and homemade doweling jigs, using a drill press and so on. Years ago I switched to a plate joiner, a portable tool that takes the drudgery out of many joinery tasks. This simple tool uses a small carbide-tipped circular saw to cut a half-oval cavity in the edges of mating components. Football-shaped biscuits are glued into the cavities formed by the tool. When the biscuits absorb the moisture in the glue, they swell and expand to fit tightly in the joint. I've always liked the simplicity of the layout needed to use this tool. You place the mating pieces together as they will be joined and mark a line across the joint. Then you align the tool with the mark on each piece and make your plunge cuts. The plate joiner, which was initially a European import, was for professionals at first because of its high cost. About a dozen years ago, Freud introduced the JS100 model, which was reasonably priced. Judicious shoppers could buy one for a lot less than the $270 list price. Today you can buy an outstanding tool for between $100 to $300. |