Popular Woodworking 2000-04 № 114, страница 12

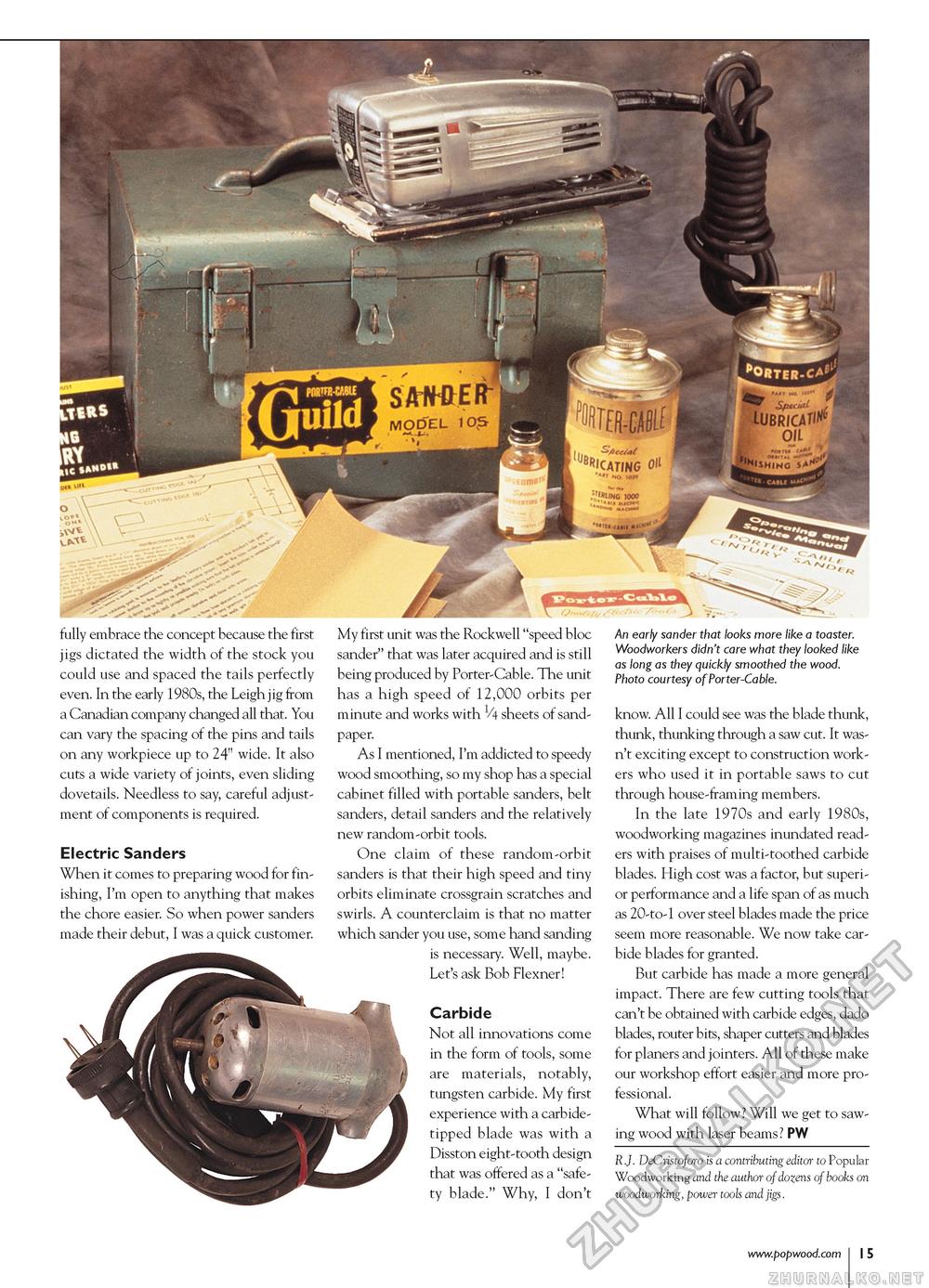

An early sander that looks more like a toaster. Woodworkers didn't care what they looked like as long as they quickly smoothed the wood. Photo courtesy of Porter-Cable. know. All I could see was the blade thunk, thunk, thunking through a saw cut. It wasn't exciting except to construction workers who used it in portable saws to cut through house-framing members. In the late 1970s and early 1980s, woodworking magazines inundated readers with praises of multi-toothed carbide blades. High cost was a factor, but superior performance and a life span of as much as 20-to-1 over steel blades made the price seem more reasonable. We now take carbide blades for granted. But carbide has made a more general impact. There are few cutting tools that can't be obtained with carbide edges, dado blades, router bits, shaper cutters and blades for planers and jointers. All of these make our workshop effort easier and more professional. What will follow? Will we get to sawing wood with laser beams? PW R.J. DeCristoforo is a contributing editor to Popular Woodworking and the author of dozens of books on woodworking, power tools and jigs. fully embrace the concept because the first jigs dictated the width of the stock you could use and spaced the tails perfectly even. In the early 1980s, the Leigh jig from a Canadian company changed all that. You can vary the spacing of the pins and tails on any workpiece up to 24" wide. It also cuts a wide variety of joints, even sliding dovetails. Needless to say, careful adjustment of components is required. Electric Sanders When it comes to preparing wood for finishing, I'm open to anything that makes the chore easier. So when power sanders made their debut, I was a quick customer. My first unit was the Rockwell "speed bloc sander" that was later acquired and is still being produced by Porter-Cable. The unit has a high speed of 12,000 orbits per minute and works with V4 sheets of sandpaper. As I mentioned, I'm addicted to speedy wood smoothing, so my shop has a special cabinet filled with portable sanders, belt sanders, detail sanders and the relatively new random-orbit tools. One claim of these random-orbit sanders is that their high speed and tiny orbits eliminate crossgrain scratches and swirls. A counterclaim is that no matter which sander you use, some hand sanding is necessary. Well, maybe. Let's ask Bob Flexner! Carbide Not all innovations come in the form of tools, some are materials, notably, tungsten carbide. My first experience with a carbide-tipped blade was with a Disston eight-tooth design that was offered as a "safety blade." Why, I don't |