Popular Woodworking 2000-04 № 114, страница 15

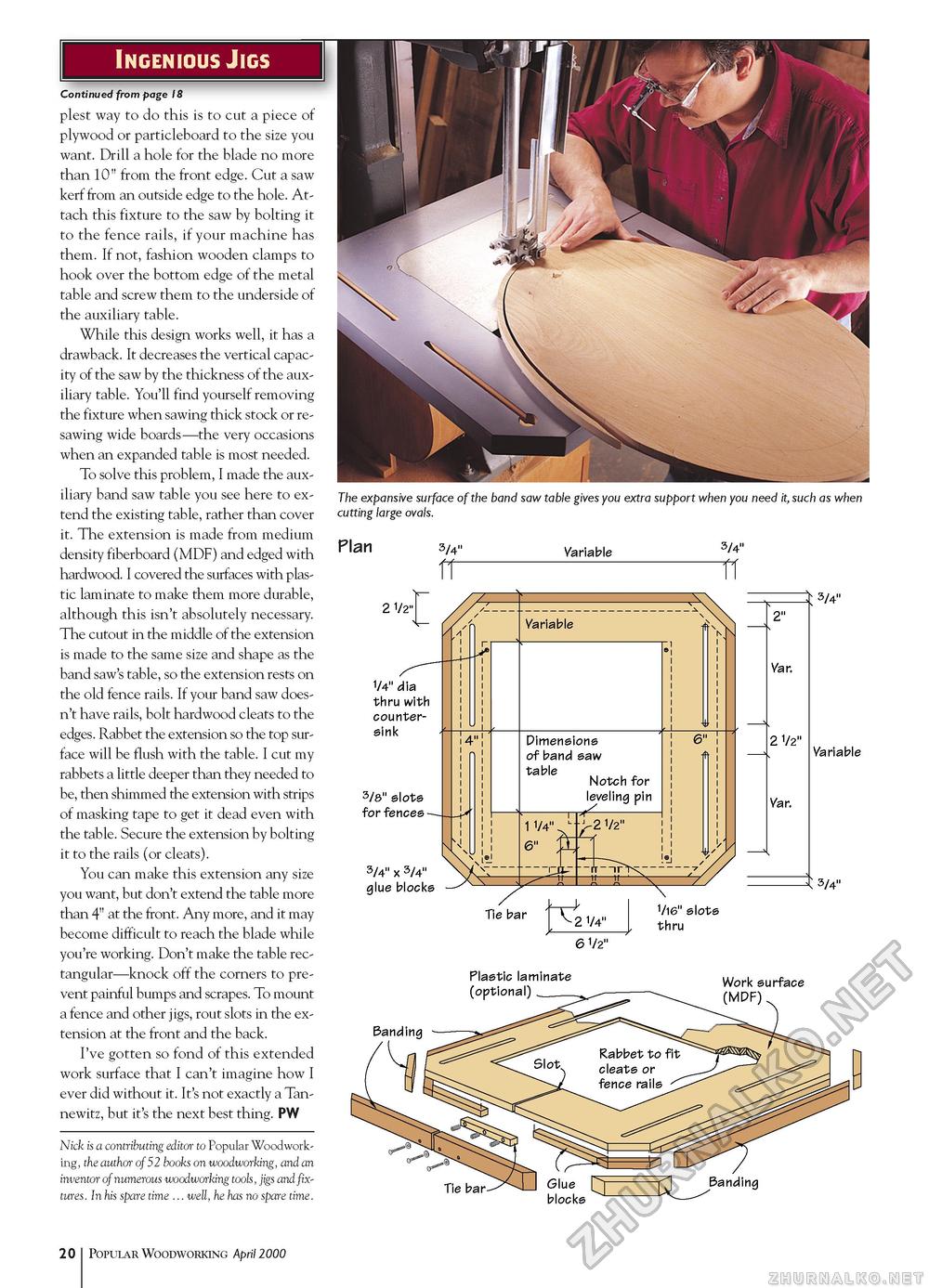

Ingenious Jigs Continued from page 18 plest way to do this is to cut a piece of plywood or particleboard to the size you want. Drill a hole for the blade no more than 10" from the front edge. Cut a saw kerf from an outside edge to the hole. Attach this fixture to the saw by bolting it to the fence rails, if your machine has them. If not, fashion wooden clamps to hook over the bottom edge of the metal table and screw them to the underside of the auxiliary table. While this design works well, it has a drawback. It decreases the vertical capacity of the saw by the thickness of the auxiliary table. You'll find yourself removing the fixture when sawing thick stock or re-sawing wide boards—the very occasions when an expanded table is most needed. To solve this problem, I made the auxiliary band saw table you see here to extend the existing table, rather than cover it. The extension is made from medium density fiberboard (MDF) and edged with hardwood. I covered the surfaces with plastic laminate to make them more durable, although this isn't absolutely necessary. The cutout in the middle of the extension is made to the same size and shape as the band saw's table, so the extension rests on the old fence rails. If your band saw doesn't have rails, bolt hardwood cleats to the edges. Rabbet the extension so the top surface will be flush with the table. I cut my rabbets a little deeper than they needed to be, then shimmed the extension with strips of masking tape to get it dead even with the table. Secure the extension by bolting it to the rails (or cleats). You can make this extension any size you want, but don't extend the table more than 4" at the front. Any more, and it may become difficult to reach the blade while you're working. Don't make the table rectangular—knock off the corners to prevent painful bumps and scrapes. To mount a fence and other jigs, rout slots in the extension at the front and the back. I've gotten so fond of this extended work surface that I can't imagine how I ever did without it. It's not exactly a Tan-newitz, but it's the next best thing. PW Nick is a contributing editor to Popular Woodworking, the author of 52 books on woodworking, and an inventor of numerous woodworking tools, jigs and fixtures. In his spare time ... well, he has no spare time. The expansive surface of the band saw table gives you extra support when you need it, such as when cutting large ovals. Plan 3/4" 4 Variable 3/4" Tf 2 1/2" 1/4" dia thru with countersink 3/8" slots for fences 3/4" x 3/4" glue blocks 4" Variable Dimensions of band saw table Notch for leveling pin 6" 2" Var. 2 1/2" Var. V 1/16" slots thru 3/4" Variable 3/4" 6 1/2" Plastic laminate (optional) Work surface (MDF). Banding Tie bar Glue blocks j^J^^^Banding 12 Popular Woodworking April 2000 |