Popular Woodworking 2000-10 № 117, страница 10

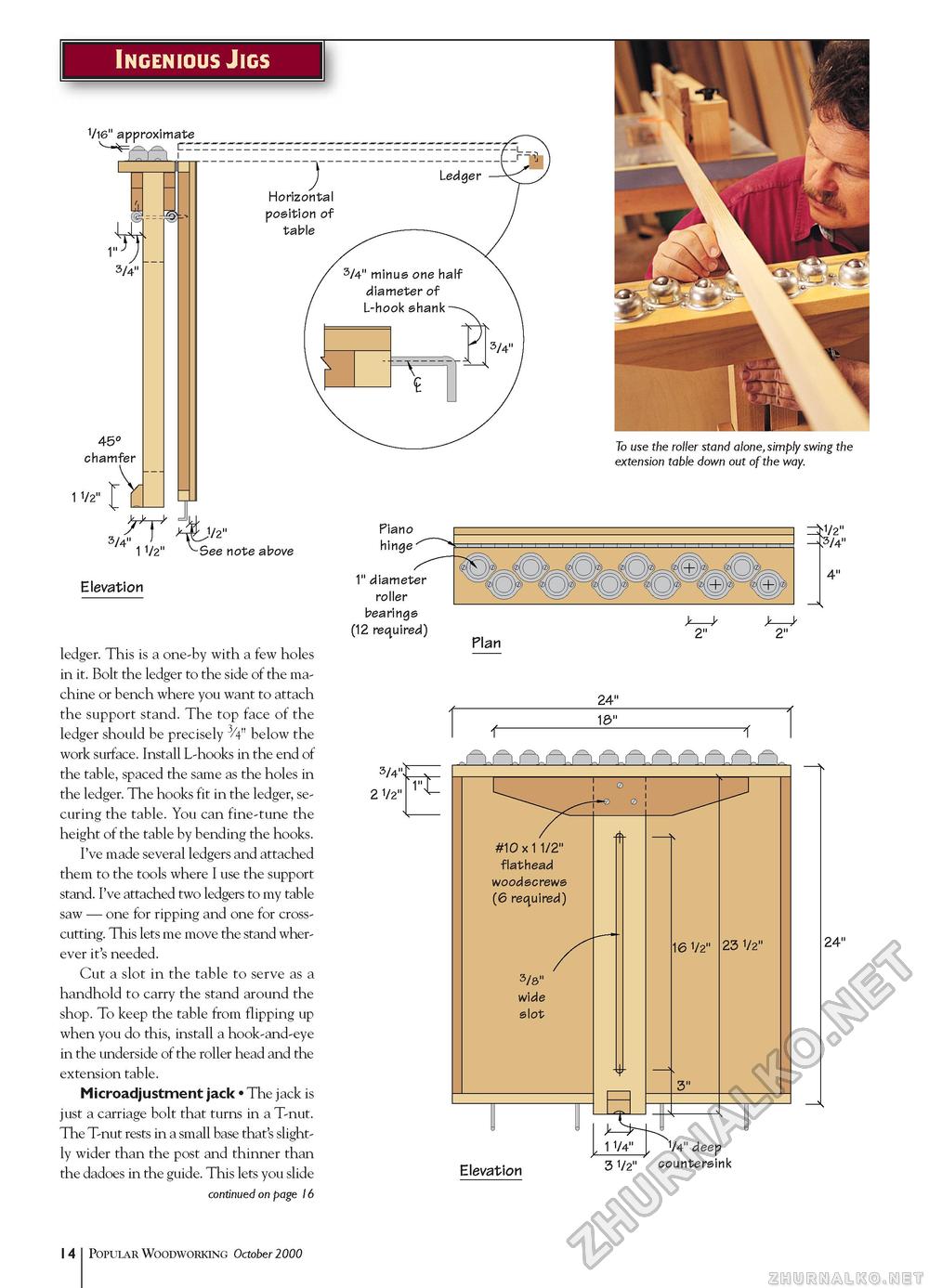

1" diameter roller bearings (12 required) ledger. This is a one-by with a few holes in it. Bolt the ledger to the side of the machine or bench where you want to attach the support stand. The top face of the ledger should be precisely 3/4" below the work surface. Install L-hooks in the end of the table, spaced the same as the holes in the ledger. The hooks fit in the ledger, securing the table. You can fine-tune the height of the table by bending the hooks. I've made several ledgers and attached them to the tools where I use the support stand. I've attached two ledgers to my table saw — one for ripping and one for cross-cutting. This lets me move the stand wherever it's needed. Cut a slot in the table to serve as a handhold to carry the stand around the shop. To keep the table from flipping up when you do this, install a hook-and-eye in the underside of the roller head and the extension table. Microadjustment jack • The jack is just a carriage bolt that turns in a T-nut. The T-nut rests in a small base that's slightly wider than the post and thinner than the dadoes in the guide. This lets you slide continued on page 16 Plan 24" 18" 3/4" 2 1/2" 1" #10 x 1 1/2" flathead woodscrews (6 required) 3/8" wide slot 24" Elevation 1/4" deep 3 1/2" countersink 12 Popular Woodworking October 2000 |