Popular Woodworking 2000-10 № 117, страница 53

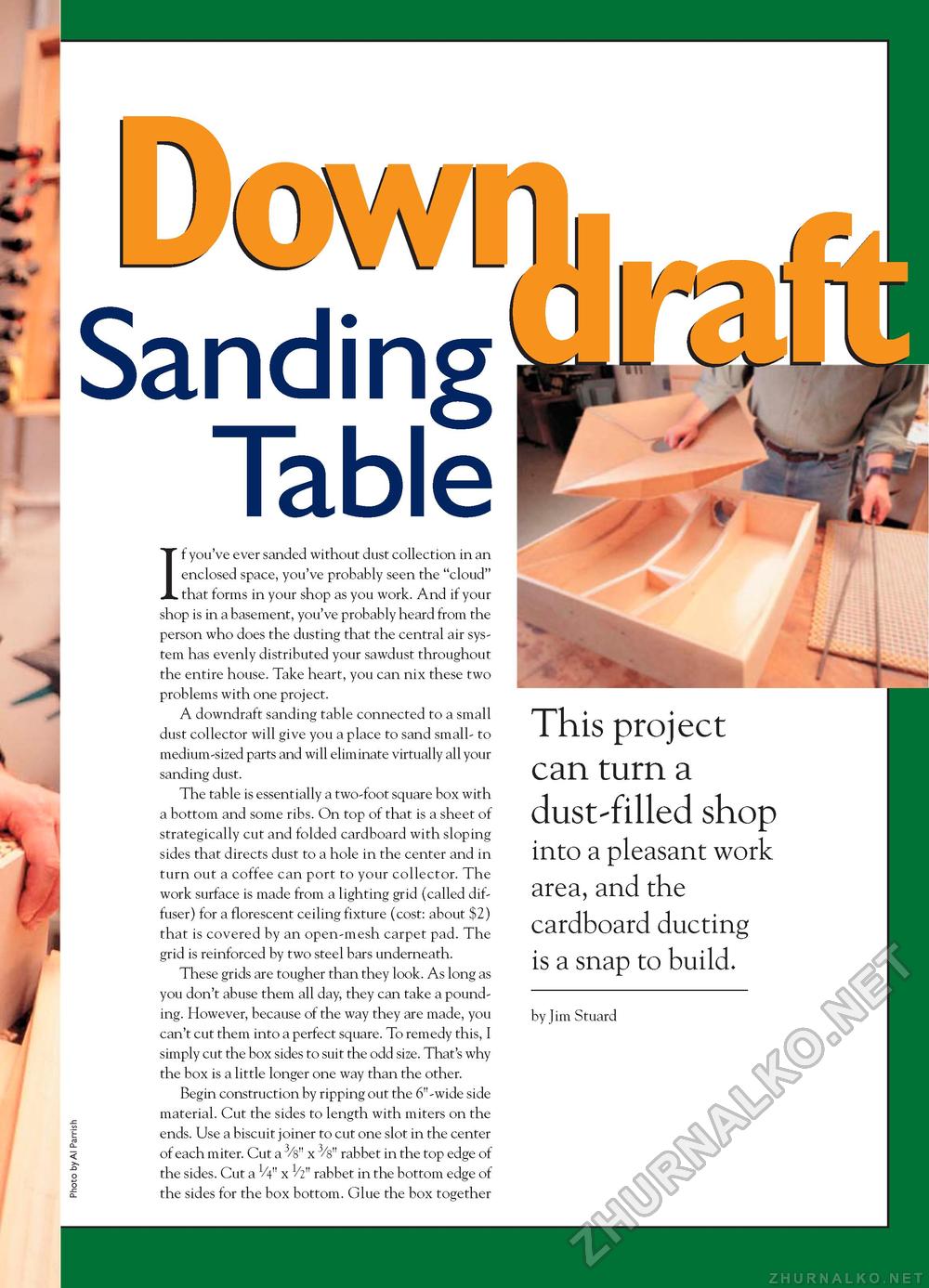

f - » I J > ) DowSanding TableIf you've ever sanded without dust collection in an enclosed space, you've probably seen the "cloud" that forms in your shop as you work. And if your shop is in a basement, you've probably heard from the person who does the dusting that the central air system has evenly distributed your sawdust throughout the entire house. Take heart, you can nix these two problems with one project. A downdraft sanding table connected to a small dust collector will give you a place to sand small- to medium-sized parts and will eliminate virtually all your sanding dust. The table is essentially a two-foot square box with a bottom and some ribs. On top of that is a sheet of strategically cut and folded cardboard with sloping sides that directs dust to a hole in the center and in turn out a coffee can port to your collector. The work surface is made from a lighting grid (called dif-fuser) for a florescent ceiling fixture (cost: about $2) that is covered by an open-mesh carpet pad. The grid is reinforced by two steel bars underneath. These grids are tougher than they look. As long as you don't abuse them all day, they can take a pounding. However, because of the way they are made, you can't cut them into a perfect square. To remedy this, I simply cut the box sides to suit the odd size. That's why the box is a little longer one way than the other. Begin construction by ripping out the 6"-wide side material. Cut the sides to length with miters on the ends. Use a biscuit joiner to cut one slot in the center of each miter. Cut a 3/s" x 3/s" rabbet in the top edge of the sides. Cut a V4" x 1/2" rabbet in the bottom edge of the sides for the box bottom. Glue the box together This project can turn a dust-filled shop into a pleasant work area, and the cardboard ducting is a snap to build. by Jim Stuard |