Popular Woodworking 2000-12 № 119, страница 11

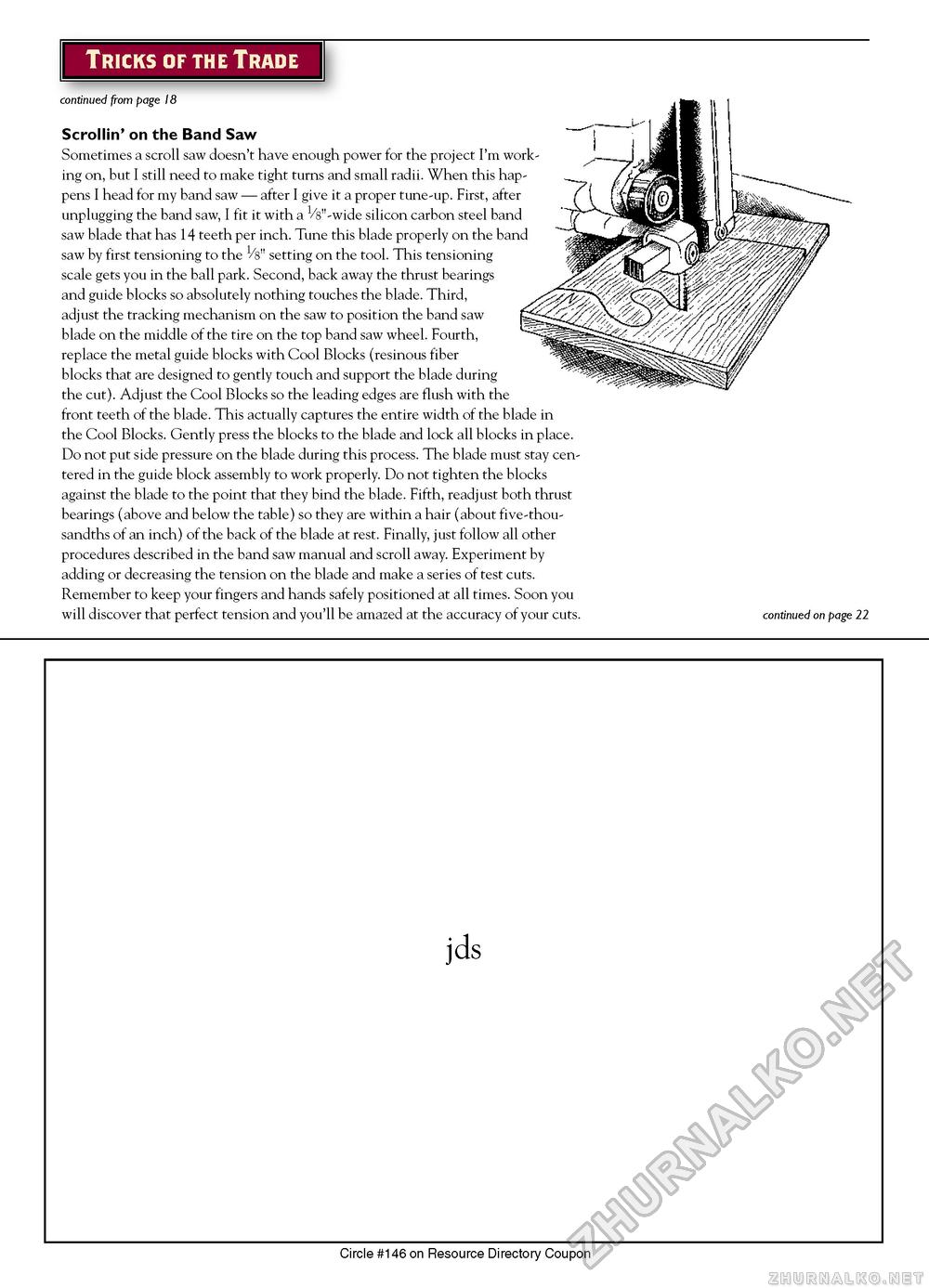

continued from page 18 Scrollin' on the Band Saw Sometimes a scroll saw doesn't have enough power for the project I'm working on, but I still need to make tight turns and small radii. When this happens I head for my band saw — after I give it a proper tune-up. First, after unplugging the band saw, I fit it with a V^'-wide silicon carbon steel band saw blade that has 14 teeth per inch. Tune this blade properly on the band saw by first tensioning to the Vs" setting on the tool. This tensioning scale gets you in the ball park. Second, back away the thrust bearings and guide blocks so absolutely nothing touches the blade. Third, > adjust the tracking mechanism on the saw to position the band saw blade on the middle of the tire on the top band saw wheel. Fourth, replace the metal guide blocks with Cool Blocks (resinous fiber blocks that are designed to gently touch and support the blade during the cut). Adjust the Cool Blocks so the leading edges are flush with the front teeth of the blade. This actually captures the entire width of the blade in the Cool Blocks. Gently press the blocks to the blade and lock all blocks in place. Do not put side pressure on the blade during this process. The blade must stay centered in the guide block assembly to work properly. Do not tighten the blocks against the blade to the point that they bind the blade. Fifth, readjust both thrust bearings (above and below the table) so they are within a hair (about five-thousandths of an inch) of the back of the blade at rest. Finally, just follow all other procedures described in the band saw manual and scroll away. Experiment by adding or decreasing the tension on the blade and make a series of test cuts. Remember to keep your fingers and hands safely positioned at all times. Soon you will discover that perfect tension and you'll be amazed at the accuracy of your cuts. continued on page 22 jds Circle #146 on Resource Directory Coupon |