Popular Woodworking 2000-12 № 119, страница 10

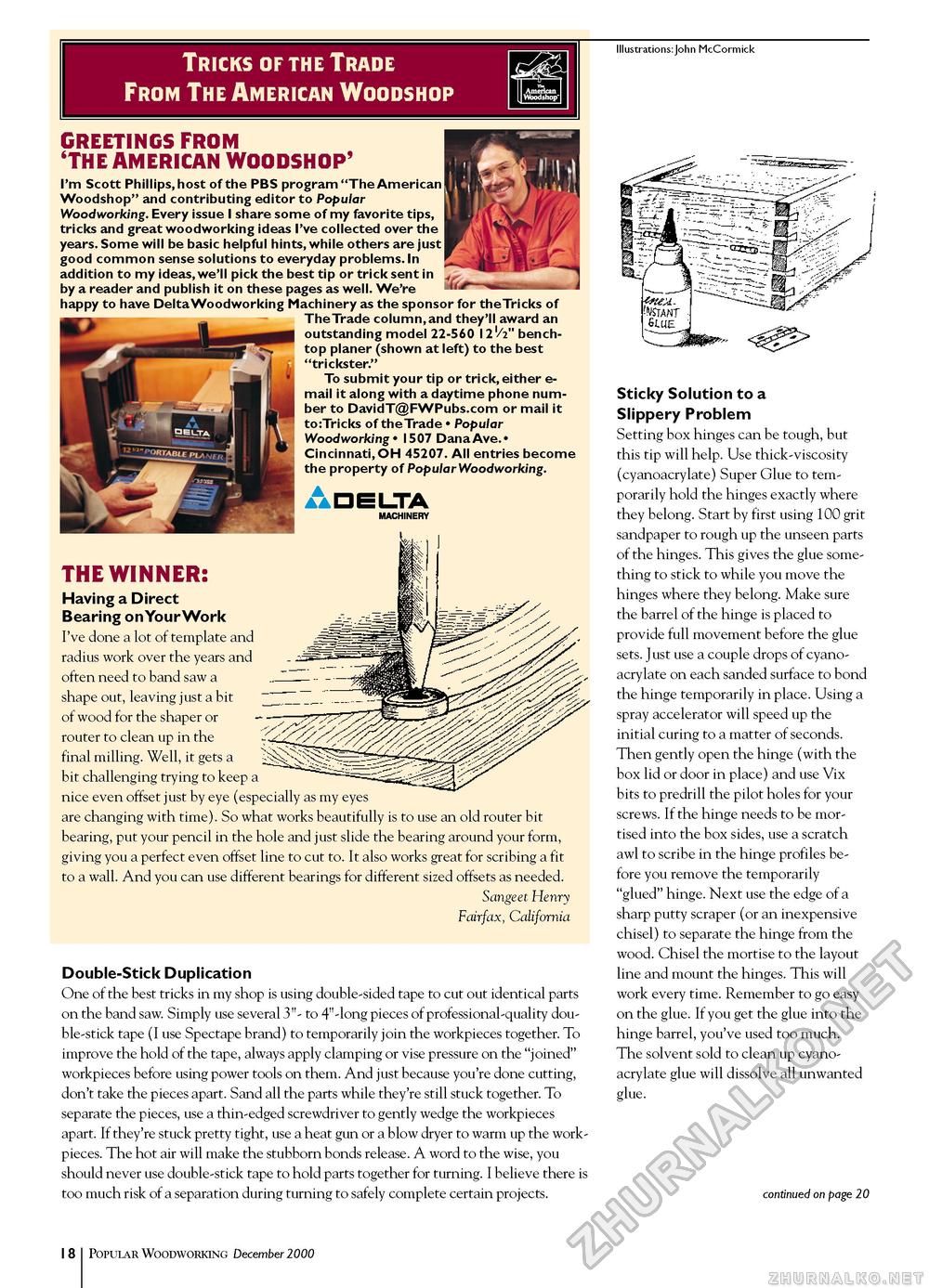

Tricks of the Trade From The American Woodshop Illustrations:John McCormick GREETINGS FROM 'THE AMERICAN WOODSHOP' I'm Scott Phillips, host of the PBS program "The American Woodshop" and contributing editor to Popular Woodworking. Every issue I share some of my favorite tips, tricks and great woodworking ideas I've collected over the years. Some will be basic helpful hints, while others are just good common sense solutions to everyday problems. In addition to my ideas, we'll pick the best tip or trick sent in by a reader and publish it on these pages as well. We're happy to have Delta Woodworking Machinery as the sponsor for theTricks of TheTrade column,and they'll award an outstanding model 22-560 l2'/2" bench-top planer (shown at left) to the best "trickster." To submit your tip or trick, either email it along with a daytime phone number to DavidT@FWPubs.com or mail it to:Tricks of the Trade • Popular Woodworking • 1507 Dana Ave.^ Cincinnati,OH 45207. All entries become the property of Popular Woodworking. Adelta the winner: Having a Direct Bearing onYourWork I've done a lot of template and radius work over the years and often need to band saw a shape out, leaving just a bit of wood for the shaper or router to clean up in the final milling. Well, it gets a bit challenging trying to keep a nice even offset just by eye (especially as my eyes are changing with time). So what works beautifully is to use an old router bit bearing, put your pencil in the hole and just slide the bearing around your form, giving you a perfect even offset line to cut to. It also works great for scribing a fit to a wall. And you can use different bearings for different sized offsets as needed. Sangeet Henry Fairfax, California Double-Stick Duplication One of the best tricks in my shop is using double-sided tape to cut out identical parts on the band saw. Simply use several 3"- to 4"-long pieces of professional-quality double-stick tape (I use Spectape brand) to temporarily join the workpieces together. To improve the hold of the tape, always apply clamping or vise pressure on the "joined" workpieces before using power tools on them. And just because you're done cutting, don't take the pieces apart. Sand all the parts while they're still stuck together. To separate the pieces, use a thin-edged screwdriver to gently wedge the workpieces apart. If they're stuck pretty tight, use a heat gun or a blow dryer to warm up the work-pieces. The hot air will make the stubborn bonds release. A word to the wise, you should never use double-stick tape to hold parts together for turning. I believe there is too much risk of a separation during turning to safely complete certain projects. Sticky Solution to a Slippery Problem Setting box hinges can be tough, but this tip will help. Use thick-viscosity (cyanoacrylate) Super Glue to temporarily hold the hinges exactly where they belong. Start by first using 100 grit sandpaper to rough up the unseen parts of the hinges. This gives the glue something to stick to while you move the hinges where they belong. Make sure the barrel of the hinge is placed to provide full movement before the glue sets. Just use a couple drops of cyano-acrylate on each sanded surface to bond the hinge temporarily in place. Using a spray accelerator will speed up the initial curing to a matter of seconds. Then gently open the hinge (with the box lid or door in place) and use Vix bits to predrill the pilot holes for your screws. If the hinge needs to be mortised into the box sides, use a scratch awl to scribe in the hinge profiles before you remove the temporarily "glued" hinge. Next use the edge of a sharp putty scraper (or an inexpensive chisel) to separate the hinge from the wood. Chisel the mortise to the layout line and mount the hinges. This will work every time. Remember to go easy on the glue. If you get the glue into the hinge barrel, you've used too much. The solvent sold to clean up cyano-acrylate glue will dissolve all unwanted glue. continued on page 20 18 Popular Woodworking December 1000 |